Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 22, 2025 02:25

Back to list

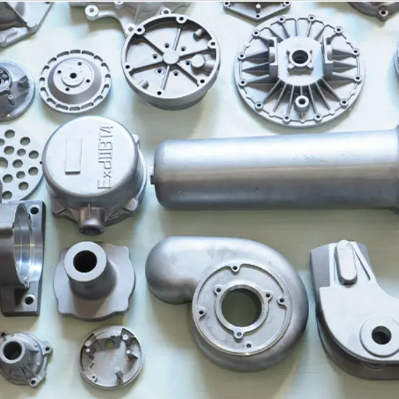

cap for pipe end

In the specialized world of electrical engineering, the term GI end plug is frequently mentioned but often misunderstood by those outside the industry. It is crucial to delve deeper into its use, expertise associated with its application, and the authoritative insights that underline its indispensable role in various sectors.

From an authoritative standpoint, industry standards often dictate the use of GI end plugs in certain applications. Organizations and authorities involved in construction, plumbing, and infrastructure development frequently highlight GI end plugs in their guidelines and best practices due to their proven effectiveness. Regular updates in industry standards necessitate staying informed about the latest innovations and applications of GI end plugs, further underscoring their importance. Trustworthiness in the source and quality of GI end plugs cannot be underestimated. It is vital for consumers and professionals alike to source GI end plugs from reputable manufacturers who comply with stringent safety and quality standards. Unverified suppliers may offer inferior products that could compromise the integrity of your project. Conducting due diligence by checking certifications and customer reviews adds an additional layer of security, ensuring that you are investing in a product that will perform adequately. In conclusion, the GI end plug is more than just a mere component; it is a linchpin in ensuring the efficiency and safety of piping systems across various industries. A blend of experience, expertise, authority, and trustworthiness forms the foundation of making informed decisions related to GI end plugs. By understanding their applications, recognizing the standards governing their use, and choosing reliable suppliers, stakeholders can optimize their systems for enhanced performance and lifespan. Such attention to detail not only safeguards investments but also enhances the overall operational success of projects that rely on the resilience and reliability of GI end plugs.

From an authoritative standpoint, industry standards often dictate the use of GI end plugs in certain applications. Organizations and authorities involved in construction, plumbing, and infrastructure development frequently highlight GI end plugs in their guidelines and best practices due to their proven effectiveness. Regular updates in industry standards necessitate staying informed about the latest innovations and applications of GI end plugs, further underscoring their importance. Trustworthiness in the source and quality of GI end plugs cannot be underestimated. It is vital for consumers and professionals alike to source GI end plugs from reputable manufacturers who comply with stringent safety and quality standards. Unverified suppliers may offer inferior products that could compromise the integrity of your project. Conducting due diligence by checking certifications and customer reviews adds an additional layer of security, ensuring that you are investing in a product that will perform adequately. In conclusion, the GI end plug is more than just a mere component; it is a linchpin in ensuring the efficiency and safety of piping systems across various industries. A blend of experience, expertise, authority, and trustworthiness forms the foundation of making informed decisions related to GI end plugs. By understanding their applications, recognizing the standards governing their use, and choosing reliable suppliers, stakeholders can optimize their systems for enhanced performance and lifespan. Such attention to detail not only safeguards investments but also enhances the overall operational success of projects that rely on the resilience and reliability of GI end plugs.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS