Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 17, 2025 17:05

Back to list

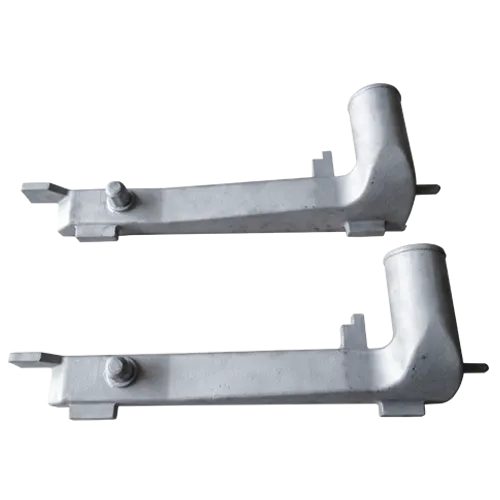

efr turbine housing

The evolving demands of the automotive and aerospace industries have pushed the boundaries of engineering and design, particularly in components that boost performance and efficiency. One such critical component is the EFR turbine housing. This element is not only instrumental in enhancing vehicle performance but also requires an integration of cutting-edge technology and precision engineering.

The boost in performance afforded by an EFR turbine housing doesn't come at the expense of reliability. Real-world experience and rigorous testing underscore the trustworthiness of this component; subjected to extensive dynamometer tests, these housings are evaluated under scenarios that replicate extreme racing conditions. Such empirical testing validates their resilience and assures end-users of their reliability in demanding applications. In terms of authoritativeness, choosing an EFR turbine housing confers the assurance of a component that adheres to and often surpasses industry standards. Prominent manufacturers of these housings work closely with automotive engineers and performance specialists, ensuring that every EFR unit not only meets OEM requirements but also offers enhancements tailored to niche applications. Such collaborations reflect a commitment to quality and performance that sets the benchmark in turbocharger technology. For automotive engineers and performance enthusiasts seeking a potent upgrade, the EFR turbine housing represents not just a high-performance component but a confluence of proven engineering principles and cutting-edge technology. It's not just about increased horsepower or improved acceleration; it's about achieving these gains with a component that epitomizes reliability and precision. The narrative of EFR turbine housing illustrates a saga of innovation that has consistently catered to the quest for excellence in high-performance environments. It is a product of engineering excellence, reflecting an unparalleled understanding of the intricate dynamics involved in turbocharger performance enhancement. For those invested in the relentless pursuit of automotive superiority, the EFR turbine housing remains an indispensable ally.

The boost in performance afforded by an EFR turbine housing doesn't come at the expense of reliability. Real-world experience and rigorous testing underscore the trustworthiness of this component; subjected to extensive dynamometer tests, these housings are evaluated under scenarios that replicate extreme racing conditions. Such empirical testing validates their resilience and assures end-users of their reliability in demanding applications. In terms of authoritativeness, choosing an EFR turbine housing confers the assurance of a component that adheres to and often surpasses industry standards. Prominent manufacturers of these housings work closely with automotive engineers and performance specialists, ensuring that every EFR unit not only meets OEM requirements but also offers enhancements tailored to niche applications. Such collaborations reflect a commitment to quality and performance that sets the benchmark in turbocharger technology. For automotive engineers and performance enthusiasts seeking a potent upgrade, the EFR turbine housing represents not just a high-performance component but a confluence of proven engineering principles and cutting-edge technology. It's not just about increased horsepower or improved acceleration; it's about achieving these gains with a component that epitomizes reliability and precision. The narrative of EFR turbine housing illustrates a saga of innovation that has consistently catered to the quest for excellence in high-performance environments. It is a product of engineering excellence, reflecting an unparalleled understanding of the intricate dynamics involved in turbocharger performance enhancement. For those invested in the relentless pursuit of automotive superiority, the EFR turbine housing remains an indispensable ally.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS