Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Custom Cast Iron Foundry Solutions for Unique Design and Manufacturing Needs

The Evolution and Importance of Custom Cast Iron Foundries

Cast iron has long been a fundamental material in various industries, ranging from automotive to construction, and custom cast iron foundries play a crucial role in its production. These specialized foundries focus on producing tailored cast iron components that meet specific requirements of clients, ensuring optimal performance and efficacy in end-use applications.

Historical Context

The origins of cast iron can be traced back to ancient China and its use expanded over the centuries, finding its way to Europe and eventually into modern factories. The flexibility of cast iron as a material, combined with its durability and excellent casting characteristics, made it pivotal during the Industrial Revolution. The invention of mechanized processes for casting iron allowed for greater production quantities and precision, setting the stage for the rise of custom foundries.

What is a Custom Cast Iron Foundry?

A custom cast iron foundry specializes in producing cast iron products according to specific designs and specifications provided by clients. Unlike mass-production foundries that create standardized parts, custom foundries focus on bespoke solutions. This process includes creating molds tailored to the client's requirements, followed by the pouring of molten iron into these molds. Once cooled, the castings are removed, trimmed, and further processed to meet the desired finish and fit.

The Advantages of Custom Cast Iron Foundries

1. Tailored Solutions One of the primary advantages of custom foundries is their ability to produce components that meet unique specifications. Industries such as aerospace, automotive, and machinery often have particular needs that off-the-shelf products cannot fulfill. Custom foundries work closely with clients to understand their requirements, leading to innovations that enhance performance.

2. Quality and Precision Custom foundries maintain stringent quality control measures to ensure that every piece meets the necessary standards. Using advanced technologies, such as computer-aided design (CAD) and simulation tools, these foundries can anticipate potential issues and refine designs before the actual production process starts.

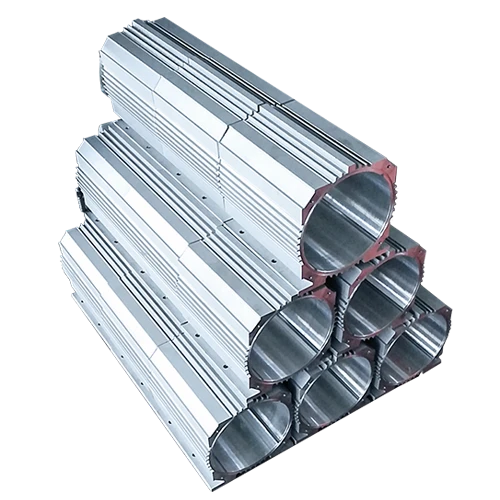

custom cast iron foundry

3. Material Versatility Cast iron can be formulated in various ways to achieve specific attributes, such as tensile strength, machinability, and wear resistance. Custom foundries often work with different grades of cast iron, including gray iron, ductile iron, and malleable iron, allowing for optimal material selection based on the specific application.

4. Innovative Techniques Custom foundries often lead the way in developing and implementing new casting techniques. For example, advancements in core manufacturing and 3D printing technology have revolutionized mold-making processes, reducing lead times and costs while improving product quality.

Environmental Considerations

In recent years, the environmental impact of manufacturing processes has come under scrutiny. Custom cast iron foundries are embracing sustainable practices by optimizing their operations to reduce waste and energy consumption. Many foundries are now implementing recycling initiatives for scrap metal and used sand, alongside employing energy-efficient furnaces and production techniques. This not only reduces their carbon footprint but also enhances their appeal to eco-conscious clients.

Future Trends

Looking ahead, the demand for custom cast iron components is expected to grow. As industries increasingly prioritize customization and specialized applications, custom foundries are well-positioned to take advantage of this trend. The transition towards Industry 4.0, characterized by automation, data exchange, and smart manufacturing, will likely further enhance the capabilities of custom foundries. This advancement will enable them to respond more efficiently to client demands and manage production dynamically.

Conclusion

Custom cast iron foundries are vital to many industries, providing the tailored solutions necessary for a wide array of applications. By emphasizing quality, precision, and innovation, these foundries not only cater to current industry needs but are also preparing for future challenges. As the business landscape continues to evolve, custom foundries will remain essential providers of cutting-edge cast iron solutions, driving innovation and progress across multiple sectors. Their ability to adapt and embrace new technologies will ensure their relevance in the ever-changing industrial landscape.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025