Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Connectors for Pump Systems-Hebei Yuanda Trade Co., Ltd.|Precision Castings,Resin Sand Casting

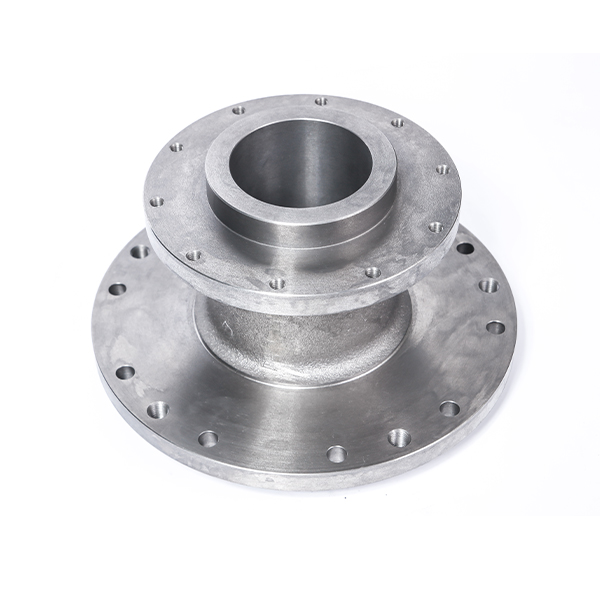

Introduction to Connector Castings

Connector castings are essential components in pump systems, serving as vital links between various mechanical parts and piping networks. These metal castings, typically fabricated from materials like cast iron, stainless steel, or aluminum alloys, play a crucial role in ensuring the operational efficiency and structural integrity of pumping equipment. The design and material selection of these connectors directly impact the performance, reliability, and longevity of pump systems.

As the backbone of fluid handling systems, high-quality connector castings help prevent leaks, reduce mechanical failures, and maintain optimal pressure levels. Their importance is underscored by the need for precision in both shape and dimensional accuracy, which are critical for proper sealing and mechanical compatibility in pump applications.

Key Features and Advantages

Material Selection and Durability

Hebei Yuanda Trade Co., Ltd. specializes in producing connector castings using premium materials such as GG25-Cast iron and advanced alloys. These materials offer exceptional corrosion resistance, wear resistance, and pressure tolerance, making them ideal for demanding industrial environments.

The company's expertise in resin sand casting technology ensures that each component meets rigorous quality standards. This process allows for precise control over material properties, resulting in castings that maintain structural integrity under extreme operating conditions.

Precision Engineering

One of the standout features of these connector castings is their high shape accuracy. Through the use of fine molds and state-of-the-art casting equipment, Hebei Yuanda ensures that each component adheres to strict dimensional tolerances. This precision is critical for maintaining proper sealing in pump systems, where even minor deviations can lead to significant performance issues.

The dimensional accuracy of these castings is another key advantage. By minimizing size errors during the casting process, the company ensures that components meet the exact specifications required for seamless integration into pump assemblies.

Surface Quality and Efficiency

The smooth surface finish of these castings is achieved through advanced manufacturing techniques that eliminate defects like sand holes and air pockets. This not only reduces the need for post-casting machining but also enhances the overall efficiency and service life of pump systems.

As noted in NIST research, surface quality in casting components directly impacts mechanical performance and maintenance requirements. Hebei Yuanda's commitment to excellence in this area ensures that their connectors contribute to reduced downtime and lower operational costs for end-users.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | GG25-Cast iron, stainless steel, aluminum alloys |

| Weight Range | 5-50kg |

| Casting Process | Resin Sand Casting |

| Shape Accuracy | High precision (±0.1mm) |

| Surface Finish | Smooth, defect-free (Ra ≤ 3.2μm) |

| Corrosion Resistance | Enhanced through material selection and surface treatments |

Applications in Industrial Pump Systems

Hebei Yuanda's connector castings are widely used in various pump applications, including:

- Water pump systems for municipal and industrial water treatment

- Chemical processing equipment requiring corrosion-resistant components

- Oil and gas pumping systems for high-pressure environments

- HVAC systems for temperature-controlled fluid circulation

The versatility of these connectors is evident in their ability to adapt to different operating conditions. Whether in high-temperature environments or corrosive chemical solutions, Hebei Yuanda's products maintain their structural integrity and performance.

Company Background and Expertise

Founded as Hebei Yuanda Trade Co., Ltd., the company has established itself as a leading manufacturer of precision casting solutions. With over a decade of experience in the industry, they specialize in producing high-quality pump components that meet international standards.

The company's commitment to innovation is reflected in their adoption of advanced casting technologies. Their production facilities are equipped with modern machinery that enables efficient mass production while maintaining strict quality control. This approach not only reduces energy consumption and labor costs but also ensures consistent product quality.

Hebei Yuanda's customer-centric philosophy is evident in their ability to customize solutions for specific application requirements. Whether it's adjusting material composition for particular environments or modifying design specifications, the company provides tailored support to meet diverse industrial needs.

Why Choose Hebei Yuanda Trade Co., Ltd.?

Quality Assurance

Every connector casting undergoes rigorous quality inspection to ensure compliance with international standards. The company's quality control processes include:

- Non-destructive testing (NDT) for internal defects

- Dimensional verification using precision measuring instruments

- Surface quality assessment according to industry specifications

Technical Support and Customization

Hebei Yuanda offers comprehensive technical support to help customers select the most suitable connector solutions. Their team of engineers provides guidance on material selection, design optimization, and application-specific requirements.

The company also specializes in custom casting solutions, allowing clients to specify unique dimensions, material properties, or surface treatments to meet specific operational challenges.

Global Reach and Reliable Supply Chain

With a strong presence in the international market, Hebei Yuanda ensures timely delivery of high-quality products to customers worldwide. Their efficient supply chain management and logistics network enable them to meet tight deadlines without compromising on quality.

Conclusion

High-quality connector castings are indispensable components in modern pump systems, and Hebei Yuanda Trade Co., Ltd. has established itself as a trusted provider of these critical parts. Through their expertise in precision casting, commitment to quality, and customer-focused approach, the company continues to set industry benchmarks.

As the demand for more efficient and reliable fluid handling systems grows, the role of advanced connector castings becomes increasingly important. Hebei Yuanda's innovative solutions and dedication to excellence make them a valuable partner for industries relying on high-performance pumping equipment.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

Hebei Yuanda Trade Co., Ltd. (n.d.). Product Specifications for Connectors. Retrieved from https://www.ydcastings.com/connectors-401.html

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025