Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

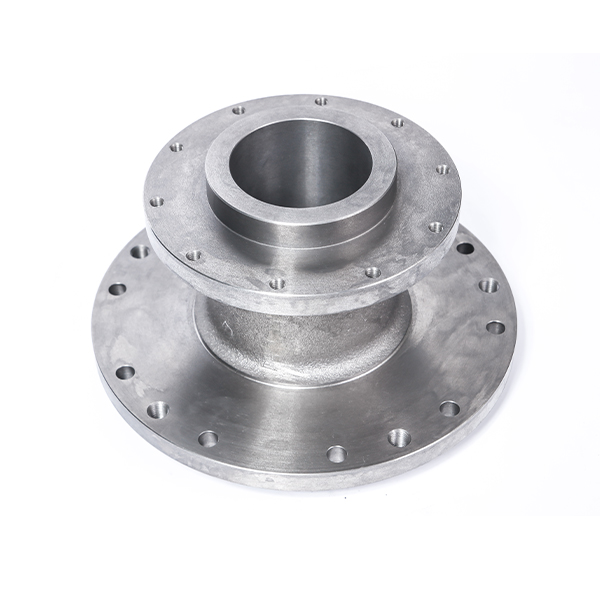

Connectors for Pump Equipment | Hebei Yuanda

Introduction to Connectors in Pump Equipment

Connectors are critical components in pump systems, serving as the vital link between various parts and piping. These connector castings are typically manufactured from robust materials such as cast iron, stainless steel, or aluminum alloys, ensuring durability and performance. The design and material selection of these components play a pivotal role in the overall efficiency and stability of pumping systems. By choosing the right connectors, users can significantly reduce the risk of leaks, damage, and system failures, ultimately improving operational reliability. For more information about pump equipment and impeller technology, visit Hebei Yuanda Trade Co., Ltd..

Key Features of Advanced Connectors

The connector castings produced by Hebei Yuanda Trade Co., Ltd. are engineered to meet the rigorous demands of modern pumping systems. One of the standout features is their high shape accuracy, achieved through the use of precision molds and advanced casting technologies. This ensures that the connectors maintain tight tolerances, which is essential for proper sealing and performance in pump applications. Additionally, these connectors exhibit excellent dimensional accuracy, minimizing size errors that could compromise the functionality of the pump. For further details on pump castings and their manufacturing processes, explore our product page.

Another critical feature is the smooth surface finish of the connectors, which eliminates defects such as sand holes or air pockets. This not only reduces the need for post-casting machining but also enhances the pump's efficiency and service life. The advanced production technology employed in the manufacturing process allows for mass production while maintaining high quality and consistency. Compared to traditional methods, this approach reduces energy consumption and labor costs, making the connectors a cost-effective solution for industrial applications.

Advantages of High-Quality Connectors

The advantages of using premium connectors in pump systems are multifaceted. First and foremost, their corrosion resistance and wear resistance ensure longevity, even in harsh environments. This is particularly important for pump equipment used in industries such as chemical processing, wastewater treatment, and oil and gas, where exposure to corrosive substances is common. By selecting connectors with these properties, operators can minimize maintenance costs and downtime.

Furthermore, the pressure resistance of these connectors is a key factor in their reliability. They are designed to withstand the mechanical stresses encountered during operation, preventing failures that could lead to costly repairs or safety hazards. The efficiency and reliability of the entire pumping system are significantly enhanced by the use of high-quality connectors, making them an indispensable component in industrial and commercial applications.

Technical Specifications of Connectors

| Parameter | Details |

|---|---|

| Product Name | Connectors |

| Weight | 5-50 kg |

| Material | GG25-Cast Iron |

| Casting Process | Resin Sand Casting |

These specifications highlight the robustness and precision of the connectors, making them suitable for a wide range of applications. For a comprehensive overview of pump castings and their technical details, visit Hebei Yuanda Trade Co., Ltd..

Application Scenarios for Connectors

Connectors are integral to the operation of pump equipment across various industries. In water treatment plants, they ensure the efficient transfer of fluids, reducing the risk of leaks and system failures. In the oil and gas sector, these connectors are used in pipelines and pumping systems, where their corrosion resistance and pressure resistance are critical. Additionally, in manufacturing facilities, connectors play a vital role in maintaining the integrity of hydraulic and pneumatic systems.

The smooth surface finish and high shape accuracy of the connectors make them ideal for applications requiring precise sealing. This is particularly important in chemical processing, where even minor leaks can lead to significant safety and environmental concerns. By leveraging the advanced casting technology employed by Hebei Yuanda Trade Co., Ltd., industries can ensure the reliability and efficiency of their pumping systems.

About Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer and supplier of high-quality pump castings and connector castings. With a commitment to innovation and excellence, the company has established itself as a trusted name in the industry. Their products are designed to meet the stringent requirements of modern pumping systems, ensuring durability, precision, and performance.

As a manufacturer of pump equipment components, Hebei Yuanda Trade Co., Ltd. leverages advanced casting technologies to produce connectors that are both cost-effective and reliable. Their expertise in resin sand casting and cast iron materials ensures that their products meet the highest standards of quality. For more information about their offerings, visit Hebei Yuanda Trade Co., Ltd..

Authoritative Citations and References

According to the National Institute of Standards and Technology (NIST), precision in casting processes is critical for ensuring the performance and reliability of industrial components. NIST's research on casting technologies highlights the importance of dimensional accuracy and material selection in manufacturing. These principles align with the standards upheld by Hebei Yuanda Trade Co., Ltd. in their production of connectors.

Additionally, NIST's guidelines on corrosion resistance in industrial materials emphasize the need for advanced coatings and material formulations. This is directly relevant to the corrosion resistance of connectors used in harsh environments, as discussed in this article.

References:

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025