Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Connectors for Pump Equipment - Hebei Yuanda Trade Co., Ltd.|Corrosion Resistant&Pressure Tolerant

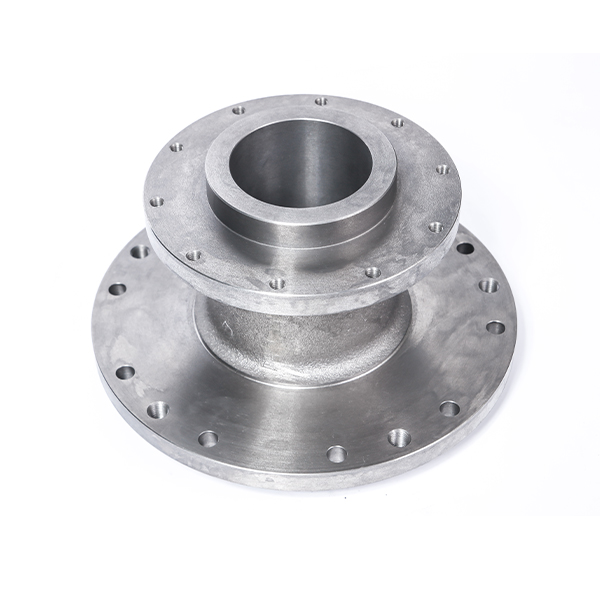

Introduction to Connector Castings

Connector castings are essential components in pump equipment, serving as critical links between various parts or piping systems. These castings are typically manufactured from durable materials such as cast iron, stainless steel, or aluminum alloys, ensuring robustness and longevity. The design and material selection of connector castings play a pivotal role in the overall performance and stability of pumping systems. High-quality connectors not only guarantee seamless operation but also significantly reduce the risk of leaks or mechanical failures. When selecting connectors, considerations such as corrosion resistance, wear resistance, and pressure tolerance are paramount. By investing in premium connector castings, users can enhance the efficiency and reliability of their pumping equipment.

Key Features and Technical Specifications

The performance of connector castings is defined by several critical parameters. Below is a detailed overview of their technical specifications:

| Parameter | Details |

|---|---|

| Material | GG25-Cast Iron, Stainless Steel, Aluminum Alloys |

| Weight | 5-50 kg |

| Casting Process | Resin Sand Casting |

| Shape Accuracy | High precision, ensuring optimal sealing performance |

| Dimensional Accuracy | Minimal size error, meeting strict engineering standards |

| Surface Quality | Smooth finish with no sand holes or air pockets |

| Production Technology | Advanced equipment for mass production and efficiency |

These specifications highlight the advanced manufacturing techniques employed to ensure that connector castings meet the rigorous demands of industrial applications. The use of resin sand casting technology not only enhances dimensional accuracy but also reduces post-casting processing, thereby lowering costs and improving production efficiency.

Applications in Pump Equipment

Connector castings are integral to the functionality of pump systems, particularly in industries such as water treatment, oil and gas, and manufacturing. Their ability to withstand high pressure and resist corrosion makes them ideal for use in water pump impeller systems and cap ends. For instance, in water pump impeller applications, connectors ensure a secure and leak-proof connection between the impeller and the pump housing, which is crucial for maintaining efficiency and preventing downtime. Similarly, cap ends require precise engineering to withstand mechanical stress and environmental factors, making high-quality connectors indispensable.

For more details on pumpe impeller and impeller on pump solutions, visit Hebei Yuanda Trade Co., Ltd..

Advantages of Premium Connector Castings

Investing in high-quality connector castings offers numerous benefits, including:

- Enhanced Durability: Materials like stainless steel and aluminum alloys provide exceptional resistance to wear and tear, ensuring long-term performance.

- Improved Sealing Performance: High shape and dimensional accuracy minimize the risk of leaks, which is critical for pumps operating under pressure.

- Cost Efficiency: Advanced production methods reduce the need for post-casting machining, lowering overall costs and production time.

- Environmental Sustainability: Modern casting technologies reduce energy consumption and material waste, aligning with global sustainability goals.

These advantages make premium connector castings a wise choice for industries prioritizing reliability and operational efficiency.

About Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer and supplier of high-quality casting solutions, specializing in pump castings, impellers, and cap ends. With a commitment to excellence, the company leverages advanced technologies and strict quality control measures to deliver products that meet international standards. Their expertise in resin sand casting ensures that each connector casting is produced with precision and consistency, catering to diverse industrial needs.

Industry Standards and Quality Assurance

As highlighted by the National Institute of Standards and Technology (NIST), adherence to industry standards is crucial for ensuring the quality and reliability of manufactured components. NIST's research and development efforts in metrology and materials science provide a framework for evaluating the performance of industrial products, including connector castings. By aligning with these standards, Hebei Yuanda Trade Co., Ltd. ensures that their products meet the highest levels of precision and durability, as emphasized in the NIST Handbook 133.

Conclusion

Connector castings are vital to the efficient operation of pump systems, and selecting the right product is essential for long-term performance. Hebei Yuanda Trade Co., Ltd. offers a comprehensive range of high-quality connectors, engineered to meet the demands of modern industries. With a focus on innovation, precision, and sustainability, the company continues to set benchmarks in the casting industry. For more information, explore their product catalog or contact their team directly.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025