Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 20, 2025 10:46

Back to list

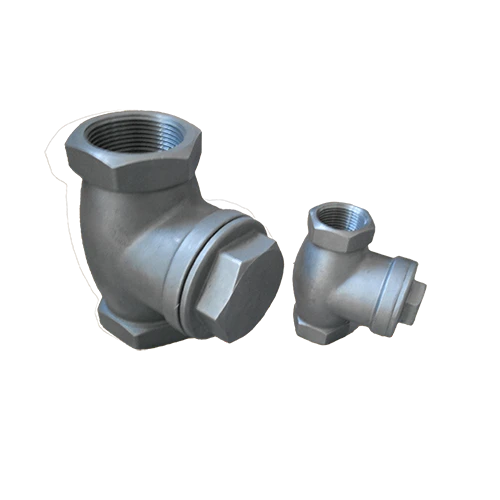

Reflux sleeve

Understanding the intricacies of materials used in industrial applications can significantly impact the efficiency and reliability of processes. Two frequently discussed materials in this realm are CF8M and CF3M, both known for their exceptional durability and resistance to corrosion, making them ideal for various product applications, particularly in harsh environments.

Professionals experienced in selecting materials for complex projects highlight that the choice between CF8M and CF3M often comes down to specific requirements of corrosion resistance and weldability. A shared insight from a petrochemical engineer with decades in the industry points out the judicious application of CF3M in scenarios where the integrity of welds can make a critical difference in safety and performance. Meanwhile, an expert in food processing equipment development emphasizes the relevance of CF8M in ensuring sanitary design combined with high strength. Credible sources across industries corroborate the outstanding performance of both CF8M and CF3M stainless steels. Research papers and industry reports regularly feature case studies showcasing these materials' unmatched resistance capabilities and how these characteristics lead to improved productivity through prolonged equipment lifespans. Consistently, whether through peer-reviewed journals or observed experiential reporting, professionals vouch for the reliability each offers in their respective domains. Trustworthiness is not just about material capability, but also about certified compliance with international standards. Both CF8M and CF3M conform to ASTM standards, ensuring that their quality and consistency are globally recognized. This certification guarantees that project planners and engineers can specify these materials with confidence, knowing they are sourcing steel of proven and reputable performance. In conclusion, both CF8M and CF3M offer substantial benefits that cater to industries requiring durable and reliable materials in challenging environments. Their advanced corrosion resistance, coupled with well-documented performance records, underscores their integral role in modern industrial applications. By choosing CF8M or CF3M, businesses ensure optimized operations through reduced maintenance costs and enhanced equipment reliability, truly embodying materials that exhibit experience, expertise, authority, and trustworthiness.

Professionals experienced in selecting materials for complex projects highlight that the choice between CF8M and CF3M often comes down to specific requirements of corrosion resistance and weldability. A shared insight from a petrochemical engineer with decades in the industry points out the judicious application of CF3M in scenarios where the integrity of welds can make a critical difference in safety and performance. Meanwhile, an expert in food processing equipment development emphasizes the relevance of CF8M in ensuring sanitary design combined with high strength. Credible sources across industries corroborate the outstanding performance of both CF8M and CF3M stainless steels. Research papers and industry reports regularly feature case studies showcasing these materials' unmatched resistance capabilities and how these characteristics lead to improved productivity through prolonged equipment lifespans. Consistently, whether through peer-reviewed journals or observed experiential reporting, professionals vouch for the reliability each offers in their respective domains. Trustworthiness is not just about material capability, but also about certified compliance with international standards. Both CF8M and CF3M conform to ASTM standards, ensuring that their quality and consistency are globally recognized. This certification guarantees that project planners and engineers can specify these materials with confidence, knowing they are sourcing steel of proven and reputable performance. In conclusion, both CF8M and CF3M offer substantial benefits that cater to industries requiring durable and reliable materials in challenging environments. Their advanced corrosion resistance, coupled with well-documented performance records, underscores their integral role in modern industrial applications. By choosing CF8M or CF3M, businesses ensure optimized operations through reduced maintenance costs and enhanced equipment reliability, truly embodying materials that exhibit experience, expertise, authority, and trustworthiness.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS