Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

High-Quality Casting Products Custom Solutions & Durability

- Fundamentals and evolution of modern casting techniques

- Precision engineering in die casting processes

- Technical capabilities of sand casting systems

- Performance comparison of leading manufacturing providers

- Design considerations for custom component development

- Industry-specific implementation case studies

- Future trajectories for complex casting solutions

(casting products)

The Critical Role of Casting Products in Modern Industry

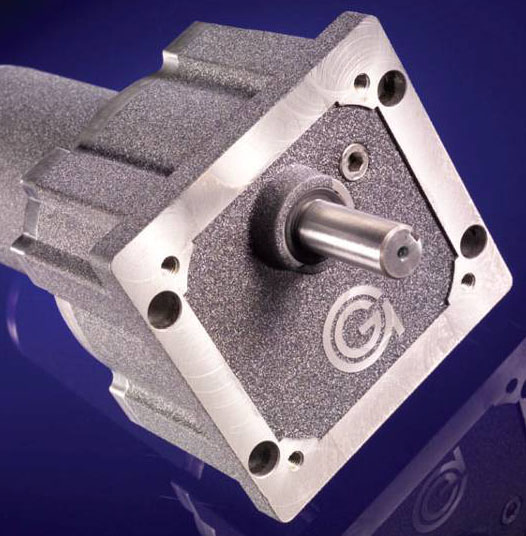

Industrial fabrication increasingly relies on advanced casting solutions to create precision components. Over 60% of manufactured metal parts now originate from casting processes, with the sector projected to reach $285 billion globally by 2028 according to industry analysts. Foundries continuously refine techniques to enhance structural integrity while reducing material waste, with recent advances achieving dimensional tolerances within ±0.15mm for complex geometries. The metallurgical properties achievable through modern die casting products

enable weight reductions of 30-50% compared to traditional machining while maintaining equivalent tensile strength. Manufacturers adopt pressure-regulated solidification to eliminate internal voids in automotive transmission housings and aerospace fittings where failure prevention is non-negotiable.

Die Casting Engineering: Accuracy at High Volume

High-pressure injection systems form the backbone of die casting production, with aluminum and zinc alloys comprising nearly 75% of industrial applications. Advanced thermal management systems enable cycle times under 90 seconds for components weighing up to 5kg, with contemporary facilities maintaining tool temperatures within ±3°C of optimal ranges. Zinc alloy die casting products demonstrate exceptional thin-wall capabilities down to 0.8mm thickness while achieving 300 MPa ultimate tensile strength, making them indispensable for electronic enclosures requiring EMI shielding and structural rigidity. Process innovations now integrate automated degating systems that reduce secondary machining operations by 40%, with fully enclosed molding cells capturing and recycling 92% of scrap materials to meet sustainability benchmarks.

Sand Casting Versatility for Complex Geometries

For oversized or geometrically intricate components exceeding 500kg, sand casting processes offer unmatched design flexibility. Organic binder formulations enable dimensional stability across parts spanning 15 meters while maintaining pattern replication accuracy within 0.1% of target dimensions. Recent improvements in resin-bonded sand systems reduce finishing requirements by 35% compared to traditional green sand methods. Foundries specializing in sand casting products increasingly deploy 3D printed molds that eliminate tooling constraints for prototypes and limited production runs. Heat treatments tailored to specific alloys enhance material characteristics; aluminum A356 castings achieve Brinell hardness levels of 85-95 following proper solution treatment and aging protocols, matching forged component performance at substantially lower production costs.

| Provider | Alloys Processed | Max Part Weight | Tolerance Standards | Prototype Lead Time | Annual Capacity |

|---|---|---|---|---|---|

| Precision Castparts | 17 (Al/Zn/Mg) | 280 kg | CT9 (ISO 8062) | 15 days | 8M units |

| Alcoa Foundry | 9 (Al/Cu) | 1800 kg | CT10 | 21 days | 3.2M units |

| Ryobi Die Casting | 6 (Al/Zn) | 75 kg | CT8 | 8 days | 12M units |

Bespoke Component Design Strategies

Developing custom casting products requires rigorous simulation during the planning phase. Top foundries deploy moldflow analysis software to predict filling patterns, calculating optimal gate placement to prevent incomplete pouring across thin sections. Material scientists recommend alloy compositions based on functional requirements; automotive brake calipers typically employ A380 aluminum (8.5-9.5% Si) for thermal stability, while marine hardware shifts toward copper-nickel blends for corrosion resistance. For complex internal channels, dissolvable salt cores maintain dimensional precision during solidification before aqueous removal. Standard post-casting treatments include T6 tempering to increase yield strength by 60% and porous impregnation sealing for hydraulic components subjected to 6000 PSI pressures. Prototype iterations have diminished from historical averages of 4-6 down to 2-3 cycles due to virtual modeling accuracy.

Industrial Implementation Case Studies

Commercial HVAC manufacturers redesigned compressor housings using die casting processes, achieving 43% weight reduction while doubling operational pressure limits to 550 PSI. Agricultural equipment producers implementing sand casting for gearbox casings report extended service intervals exceeding 10,000 operational hours under heavy particulate contamination. Telecommunications infrastructure utilizes zinc pressure die casting products for 5G antenna mounts that withstand 130mph winds without tower resonance distortion. Medical technology firms adopt magnesium casting for portable scanner components, creating radiation-shielded housings 25% lighter than previous aluminum iterations. These application scenarios validate fatigue test data showing modern casting techniques extend mean time between failures by 200-400% across multiple stress profiles when compared to fabricated alternatives.

Strategic Integration of Casting Solutions

Industrial users increasingly require casting products capable of meeting multi-variable performance thresholds. Leading aerospace manufacturers now implement dual-alloy systems within single components, applying pressure casting techniques to join titanium reinforcement structures with aluminum primary elements at metallurgical level adhesion strength. This progression permits 60% mass reduction versus conventional assemblies while maintaining rigorous FAA structural certifications. As industries shift toward electromechanical integration, foundries partner with sensor manufacturers to embed diagnostic systems during pouring that monitor thermal stress throughout product lifetimes. Material science laboratories continue developing nanocrystalline alloys for casting applications that promise grain structures five times smaller than conventional options, potentially tripling wear resistance parameters. These developments position casting methodologies for strategic expansion into demanding fields including renewable energy storage systems and advanced robotics.

(casting products)

FAQS on casting products

以下是围绕核心关键词创建的5组英文FAQ问答:Q: What are die casting products?

A: Die casting products are metal parts created by forcing molten metal under high pressure into reusable steel molds. This process enables high-volume production of complex shapes with excellent dimensional accuracy. Common applications include automotive components, electronics housings, and industrial machinery parts.

Q: What materials are typically used for casting products?

A: Casting products utilize various metals like aluminum, zinc, iron, and bronze alloys. Material selection depends on application requirements such as strength, weight, corrosion resistance, and cost-effectiveness. Aluminum is most prevalent in die casting, while iron dominates sand casting applications.

Q: How do sand casting products differ from die casting products?

A: Sand casting uses expendable sand molds for lower-volume production with larger, simpler geometries. Die casting employs permanent steel molds for high-precision, mass-produced components with finer details. Sand casting offers greater flexibility for large parts, while die casting ensures superior surface finish and tighter tolerances.

Q: What are the main advantages of casting products?

A: Casting enables cost-effective production of complex shapes with minimal material waste. It provides excellent design flexibility for integrated components that would be impractical to machine. The process also allows versatile material selection for optimal performance characteristics like durability and heat resistance.

Q: Which industries commonly use casting products?

A: Automotive manufacturing relies heavily on casting products for engine blocks, transmission cases, and structural parts. Aerospace, construction equipment, and consumer electronics industries extensively utilize precision cast components. Plumbing, valve, and hardware sectors also depend on sand casting products for valves, fittings, and heavy-duty fixtures.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025