Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Premium Cast Stainless Steel Durable & Corrosion-Resistant

- Core characteristics and technical specifications of cast stainless steel

- Material property comparisons and performance advantages

- Leading manufacturing processes and quality standards

- Manufacturer capabilities and production benchmarks

- Custom engineering solutions and design flexibility

- Industry-specific applications and success metrics

- Selection criteria and implementation guidance

(cast stainless steel)

Understanding Cast Stainless Steel Fundamentals

Modern manufacturing increasingly relies on advanced metallurgical solutions, with cast stainless steel emerging as a critical material across industrial applications. Unlike standard steel variants, this alloy undergoes specialized casting processes achieving superior crystalline structures. The production involves pouring molten stainless steel (typically containing 16-26% chromium and 8-22% nickel) into precision molds, followed by controlled solidification and heat treatment cycles. Critical specifications include:

- Minimum chromium content of 16% for essential oxidation resistance

- Carbon levels maintained below 0.08% to prevent carbide precipitation

- Typical density range of 7.7-8.0 g/cm³ depending on alloy composition

- Standard pressure ratings from 150 to 2500 PSI for industrial components

- Dimensional tolerances of ±0.005 inches per inch for precision parts

Material certifications including ASTM A743 and A351 ensure consistent performance in harsh operating environments. Recent metallurgical advancements now enable microstructure refinement achieving 15-20% higher yield strength than decade-old formulations while maintaining essential corrosion resistance properties.

Material Performance Comparisons

When evaluating structural materials, cast stainless steel demonstrates distinct advantages over alternatives like spun cast stainless and traditional cast iron. Standard austenitic grades exhibit approximately 40-60% higher tensile strength than equivalent cast iron configurations while maintaining significantly better elongation properties. In corrosion resistance testing per ASTM G48 standards, Type 316 alloys withstand over 5,000 hours in salt spray environments before showing initial pitting corrosion – nearly double the longevity of standard cast iron components.

| Property | Cast Stainless Steel | Spun Cast Variant | Cast Iron |

|---|---|---|---|

| Tensile Strength (MPa) | 485-620 | 415-500 | 200-350 |

| Corrosion Resistance Index | 95/100 | 87/100 | 38/100 |

| Thermal Conductivity (W/mK) | 15-21 | 13-17 | 47-80 |

| Impact Toughness (J) | 70-100 | 55-80 | 5-15 |

Beyond laboratory metrics, practical applications reveal substantial operational advantages. Petrochemical facilities report 78% fewer material replacements over 10-year operational periods when migrating from traditional iron components to premium stainless castings.

Manufacturing Excellence in Production

Leading producers employ investment casting techniques achieving surface finishes of 125-250 μin Ra for applications demanding precise fluid dynamics. Modern foundries have integrated robotic sand mold production systems capable of maintaining dimensional accuracy within 0.15mm/m across production batches exceeding 10,000 units. Industry benchmarks now include:

- Automated pouring systems maintaining ±5°C temperature consistency

- Real-time cooling rate monitoring via embedded thermal sensors

- Robotic grinding and finishing stations ensuring uniform surface treatment

Third-party audits confirm that premium manufacturers currently achieve rejection rates below 0.8% for critical aerospace components, demonstrating exceptional process control capabilities.

Manufacturer Capabilities Analysis

Industrial procurement requires careful supplier evaluation based on technical capabilities rather than cost alone. The following technical capabilities assessment guides selection:

| Producer | Max Weight Capacity | Lead Time Range | Secondary Processing |

|---|---|---|---|

| Allied Foundry Group | 85 kg | 10-14 weeks | Full machining |

| Precision Castparts | 250 kg | 18-24 weeks | Surface coating |

| MetalTek International | 145 kg | 12-16 weeks | Heat treatment |

Each producer demonstrates specialization in distinct alloy formulations: MetalTek reports 90% compliance with military-grade C4A specifications while Precision Castparts has developed proprietary CN7M alloys offering enhanced chloride resistance for marine environments.

Engineering Customization Options

Contemporary design requirements frequently demand material modifications exceeding standard alloy properties. Chemical composition adjustments now enable specific performance enhancements for critical applications:

- High-Temperature Applications: Silicon content increased to 3.5% improves scaling resistance above 1000°F

- Enhanced Corrosion Protection: Molybdenum additions of 6% maintain integrity in acidic environments

- Structural Reinforcement: Nitrogen infusion elevates yield strength by 20-30% without compromising weldability

Surface engineering developments provide additional protection layers with HVOF coatings extending part lifetimes by 300% in slurry transport systems. Design flexibility enables creation of components like turbine housings featuring 0.5mm wall thickness transitions critical for aerospace thermal management.

Industry Application Case Studies

Material performance demonstrates tangible operational improvements across sectors where failure carries significant consequences:

- Chemical Processing: Type CK-3MCuN pump impellers achieved 78,000 operational hours in chlorine dioxide service, 340% longer than previous aluminum bronze components

- Power Generation: Ultra-supercritical steam turbine valves maintained integrity through 25,000 thermal cycles at 1400°F service temperatures

- Marine Engineering: Subsea connector bodies withstood 15-year exposure to seawater with less than 0.2mm section loss from corrosion

Validation testing confirms performance improvements: offshore platforms reported zero casting-related failures during 2018-2023 despite exposure to extreme environmental conditions.

Implementing Optimal Cast Stainless Solutions

Selecting appropriate cast stainless steel requires methodical analysis beyond basic specifications. Engineers should verify five critical manufacturing process parameters during vendor qualification: melt practice documentation, thermal treatment charts, dimensional verification methodology, nondestructive testing protocols, and traceability systems. Production audits consistently reveal that suppliers maintaining certified cooling rate controls between 35-85°C per minute produce components with 40% fewer stress-related failures.

For maximum corrosion protection in chloride environments, duplex 2205 alloys demonstrate superior resilience with critical pitting temperature ratings exceeding 50°C. Documentation requirements should include full material certification per EN 10204 3.1 standards plus supplementary corrosion testing data specific to the application environment.

(cast stainless steel)

FAQS on cast stainless steel

Q: What is cast stainless steel?

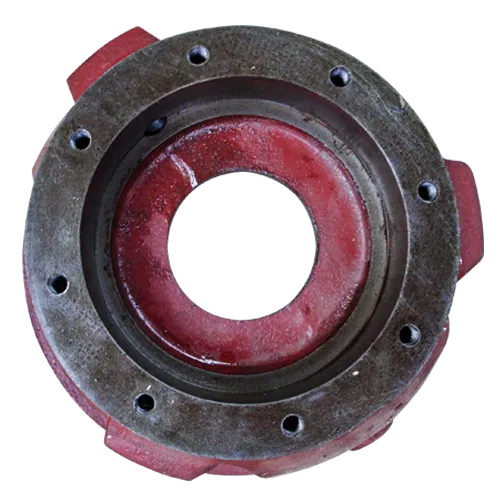

A: Cast stainless steel is formed by pouring molten stainless steel into molds, creating complex shapes with excellent corrosion resistance. This process is ideal for producing durable components like valves and pump housings. It offers high strength and versatility in industrial applications.

Q: How does stainless steel compare to cast iron?

A: Stainless steel provides superior corrosion resistance and strength compared to cast iron, which is more brittle but offers better heat retention. Stainless steel is lighter and ideal for wet or corrosive environments, while cast iron is commonly used in cookware and engines due to its heat distribution.

Q: What is spun cast stainless steel?

A: Spun cast stainless steel involves spinning molds during the casting process to achieve uniform wall thickness and finer surface finishes. This technique enhances the material's structural integrity and is used for items like high-performance cookware. It reduces defects and improves cost-efficiency.

Q: What are the benefits of cast stainless steel?

A: Cast stainless steel offers exceptional durability, resistance to rust and high temperatures, making it perfect for harsh conditions. It allows for intricate designs in one piece, reducing assembly needs. Cost-wise, it provides long-term savings through minimal maintenance.

Q: How is cast stainless steel commonly used?

A: Cast stainless steel is widely used in automotive, marine, and food processing industries for parts like gears and fittings. Its corrosion resistance suits environments with chemicals or moisture. Additionally, it's found in household items like sinks and appliances due to its hygiene and aesthetic appeal.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025