Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Brazing Cast Iron

Brazing Cast Iron Techniques and Applications

Brazing is a metal joining process that involves the use of a filler metal with a melting point above 450 °C (about 840 °F) but below that of the base metals. Unlike welding, which often involves melting the base metals, brazing relies on capillary action to draw the filler into the joint. This technique is particularly valuable when working with cast iron, given its unique properties and challenges.

Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%. It possesses excellent casting characteristics, making it ideal for complex shapes. However, its brittleness and difficulty in welding make it less suited for traditional joining methods. This is where brazing shines, as it allows for the creation of strong and reliable joints without compromising the integrity of the base material.

One of the primary benefits of brazing cast iron is its ability to dissimilar metals. While cast iron itself can be challenging to weld due to its brittle nature, the brazing process accommodates various materials. This flexibility is advantageous in applications where cast iron components need to be joined to other metals, like steel or copper. The filler metals used in brazing can be tailored to match the properties of the materials involved, ensuring a strong bond while maintaining the overall flexibility of the joint.

When brazing cast iron, selecting the right filler metal is crucial. Common choices include nickel-based and aluminum-silicon filler metals. Nickel-based fillers are particularly effective due to their excellent corrosion resistance and ability to provide high-strength joints. Aluminum-silicon fillers are favored for their lower melting points, making the brazing process more manageable and reducing the risk of thermal shock to the cast iron components.

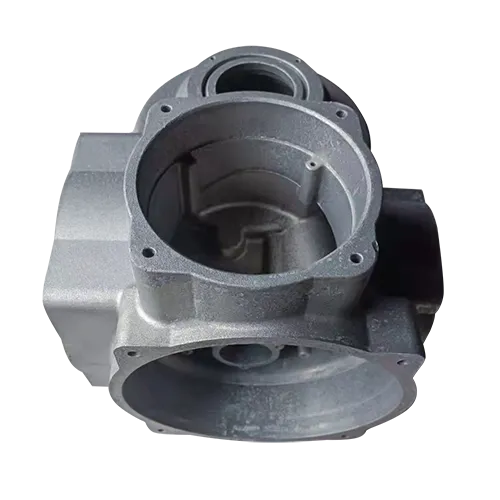

brazing cast iron

Preparation is key to successful brazing. The surfaces to be joined must be clean and free of contaminants such as oil, rust, or paint. A thorough cleaning process, which may involve mechanical grinding or chemical cleaning agents, ensures that the filler metal can adequately flow into the joint, creating a strong bond.

The brazing process typically involves heating the cast iron components in a furnace or using a torch until they reach the appropriate temperature for the filler metal. Care must be taken to avoid overheating the cast iron, as excessive heat can cause it to crack or warp. The components are usually heated to a range between 600 °C to 700 °C (1112 °F to 1292 °F), depending on the filler metal being used. After heating, the filler is introduced into the joint, where it will flow and solidify upon cooling.

One notable application of brazing cast iron is in the repair of antique or vintage machinery. These often consist of intricately designed cast iron parts that, when damaged, may be more challenging to replace than to repair. Brazing allows for the skilled restoration of these components without sacrificing their original characteristics.

In conclusion, brazing cast iron is an effective technique that offers numerous advantages over traditional welding methods. It facilitates the joining of dissimilar metals, enables the repair of fragile components, and provides the flexibility needed in various industrial applications. With the right preparation, materials, and techniques, brazing can result in durable and reliable joints, ensuring longevity and functionality in cast iron products.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025