Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 19, 2025 23:57

Back to list

bearing end cap

Bearing end caps, although frequently overlooked, play a crucial role in various industrial applications. These small components are instrumental in ensuring the longevity and efficiency of machinery, creating a noticeable impact in sectors ranging from automotive to aerospace. With a deeper understanding of bearing end caps, businesses can optimize their use and witness significant improvements in performance.

Trustworthiness is another significant factor in this niche market. Given the technical nature of bearing end caps, businesses must rely on manufacturers that uphold stringent quality standards. Certifications and adherence to international regulations provide assurance that the end caps are dependable and high-performing. Furthermore, trusted manufacturers often provide detailed documentation and customer support, ensuring that clients have the necessary information and assistance to deploy the components successfully. Incorporating state-of-the-art technology has become increasingly essential in producing bearing end caps. Modern manufacturing techniques, such as CNC machining and advanced metallurgy, have allowed for higher precision and quality control. These advancements not only increase the overall reliability of the bearing end caps but also enhance their adaptability across different industrial applications. It is also noteworthy to mention the sustainability aspect of bearing end caps. Modern industrial consumers are increasingly aware of their environmental footprint, and manufacturers are responding by exploring eco-friendlier materials and production methods. This approach not only aligns with global sustainability goals but also meets the demands of consumers who prioritize environmental responsibility. In conclusion, bearing end caps are an indispensable component in the complex machinery of various industries. Their correct application results in improved operational efficiency and reduced maintenance costs, while their production demands precision and expertise from manufacturers. Trustworthy and authoritative manufacturers are critical to ensuring high-quality products that cater to the unique needs of each sector. As technology and sustainability drive future advancements, businesses that harness these improvements will undoubtedly see a competitive advantage in their operational capabilities.

Trustworthiness is another significant factor in this niche market. Given the technical nature of bearing end caps, businesses must rely on manufacturers that uphold stringent quality standards. Certifications and adherence to international regulations provide assurance that the end caps are dependable and high-performing. Furthermore, trusted manufacturers often provide detailed documentation and customer support, ensuring that clients have the necessary information and assistance to deploy the components successfully. Incorporating state-of-the-art technology has become increasingly essential in producing bearing end caps. Modern manufacturing techniques, such as CNC machining and advanced metallurgy, have allowed for higher precision and quality control. These advancements not only increase the overall reliability of the bearing end caps but also enhance their adaptability across different industrial applications. It is also noteworthy to mention the sustainability aspect of bearing end caps. Modern industrial consumers are increasingly aware of their environmental footprint, and manufacturers are responding by exploring eco-friendlier materials and production methods. This approach not only aligns with global sustainability goals but also meets the demands of consumers who prioritize environmental responsibility. In conclusion, bearing end caps are an indispensable component in the complex machinery of various industries. Their correct application results in improved operational efficiency and reduced maintenance costs, while their production demands precision and expertise from manufacturers. Trustworthy and authoritative manufacturers are critical to ensuring high-quality products that cater to the unique needs of each sector. As technology and sustainability drive future advancements, businesses that harness these improvements will undoubtedly see a competitive advantage in their operational capabilities.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

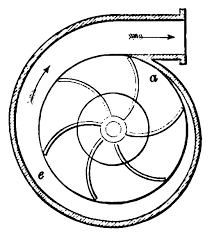

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS