Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Baffled Oil Pan for Consistent Oil Pickup & Engine Protection

The Crucial Role of Advanced Oil Sump Design in High-Performance Engines

In the intricate world of internal combustion engines, optimal lubrication is paramount for sustained performance and longevity. High-performance vehicles, especially those subjected to extreme G-forces during aggressive cornering, acceleration, or braking, face a unique challenge: preventing oil starvation. This is where the advanced design of a baffled oil pan becomes indispensable. Unlike a conventional engine sump, a baffled variant incorporates internal structures engineered to manage oil flow dynamically, ensuring that the oil pickup remains submerged even under severe vehicle dynamics. This specialized engineering prevents damaging momentary losses of oil pressure, which can lead to catastrophic engine failure and costly downtime. Our focus at YD Castings is on precision-engineered solutions, including sophisticated motor housing components and custom engine oil pan designs, that meet the rigorous demands of modern automotive and industrial applications.

Industry Trends and the Evolving Need for Specialized Engine Sumps

The automotive and industrial sectors are consistently pushing the boundaries of power, efficiency, and durability. This push directly influences the design and engineering of core engine components, including the engine sump, which functions as the primary reservoir for engine lubricant. Current trends highlight a growing demand for specialized solutions that can withstand more extreme operating conditions, from high-revving racing engines to heavy-duty industrial machinery operating in challenging environments. The advent of lighter materials, advanced manufacturing processes, and increasingly complex engine architectures necessitates a departure from simplistic oil pan designs. The market for baffled oil pan solutions is expanding as more OEMs and aftermarket specialists recognize the critical role these components play in safeguarding expensive engine assets. Furthermore, the integration of sensors and data analytics for real-time oil condition monitoring is becoming more prevalent, requiring oil pan designs that can accommodate these technologies without compromising integrity or performance. This continuous evolution underscores the need for expert manufacturers capable of delivering cutting-edge automobile oil pan solutions that integrate seamlessly with next-generation powertrain technologies.

Technical Parameters and Advanced Engineering of Baffled Oil Pan Systems

A baffled oil pan is fundamentally designed to manage the dynamic movement of engine oil within the sump. This is achieved through strategically placed internal walls, called baffles, which prevent oil sloshing away from the oil pickup tube during aggressive maneuvers or vibrations common in industrial machinery. Key technical parameters define the performance and suitability of these components:

- Material Composition: Commonly manufactured from high-grade aluminum alloys (e.g., A356, 6061-T6) for lightweight and superior thermal conductivity, or robust steel alloys for heavy-duty applications. Emerging composite materials are also gaining traction for specialized, ultra-lightweight designs.

- Capacity (Liters): Optimized to ensure sufficient oil volume for lubrication and cooling, typically ranging from 5L to 15L for performance automotive applications, and significantly higher for large industrial engines. An adequate capacity is crucial for thermal management.

- Baffle Design: Critical for effective oil control. Designs include one-way trapdoor baffles that allow oil in but restrict movement out, fixed internal walls, and integrated screens, all aimed at consistently submerging the oil pickup. The geometry is often refined through extensive Computational Fluid Dynamics (CFD) simulations to optimize oil flow.

- Mounting Points and Gasket Interface: Precision machined to ensure a perfect, leak-proof seal with the engine block, adhering to strict OEM specifications and preventing oil leaks which can lead to significant issues.

- Drain Plug and Sensor Ports: Strategically integrated for ease of maintenance (oil draining) and compatibility with essential oil temperature, pressure, and level sensors, enabling real-time monitoring of engine health.

- Surface Finish: Both internal and external surface finishes are critical for optimal oil flow dynamics and enhanced corrosion resistance. This often involves processes like anodizing or specialized coatings for aluminum pans to withstand aggressive environments.

Understanding these parameters is crucial for selecting or designing an optimal engine oil pan solution. Below is a representative table of common specifications that highlight the diverse capabilities of modern oil sump manufacturing:

| Parameter | Typical Range / Options | Key Benefit / Characteristic |

|---|---|---|

| Material | Aluminum Alloy (A356, 6061), Steel (Mild, Stainless), Carbon Fiber Composites | Optimized strength-to-weight, thermal conductivity, or extreme corrosion resistance. |

| Oil Capacity | 5L - 15L (Performance Auto), 20L - 100L+ (Industrial/Marine) | Sufficient volume for sustained lubrication, cooling, and reduced oil change intervals. |

| Baffle System Type | Trapdoor (hinged), Fixed Wall, Integrated Mesh/Screen, Combinations | Prevents oil starvation under dynamic loads (G-forces), reduces foaming. |

| Manufacturing Process | Sand Casting, Die Casting, Investment Casting, CNC Machining, Fabrication (Welding) | Achieves complex internal geometries, high dimensional accuracy, and material integrity. |

| Applicable Standards | ISO 9001:2015, ANSI/ASME, ASTM, API Specifications | Ensures consistent quality, interchangeability, and compliance with industry regulations. |

| Typical Service Life | Engine Lifetime (approx. 150,000 - 300,000+ miles or 10,000+ operating hours) | Designed for durability and reliability, matching or exceeding the lifespan of the engine itself. |

The Manufacturing Process: From Raw Material to Precision Baffled Oil Pan

The creation of a high-quality baffled oil pan involves a meticulous sequence of engineering and manufacturing steps, each critical to the final product's integrity and performance. Our process begins with the careful selection of raw materials, typically aerospace-grade aluminum alloys or high-strength steels, chosen for their specific mechanical properties, such as tensile strength, yield strength, and fatigue resistance, essential for enduring the harsh operating environment of an engine. The primary manufacturing processes employed include:

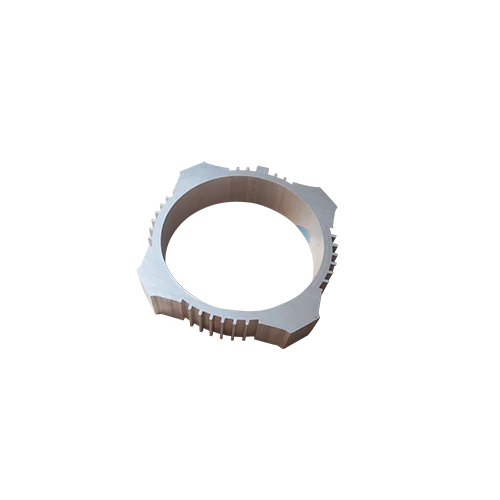

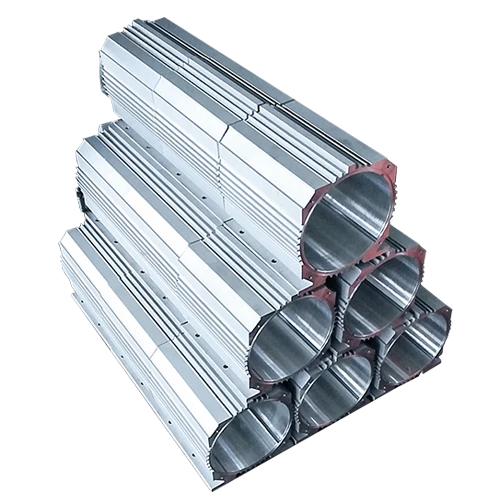

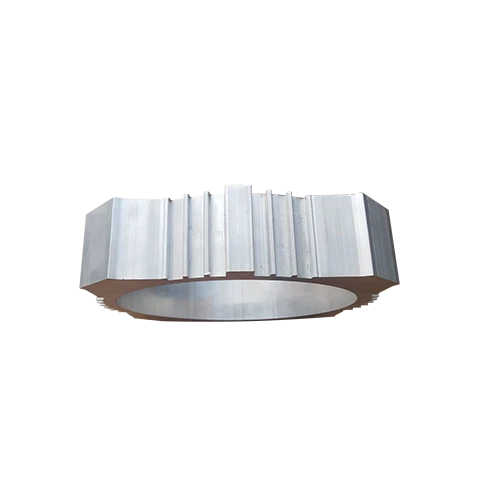

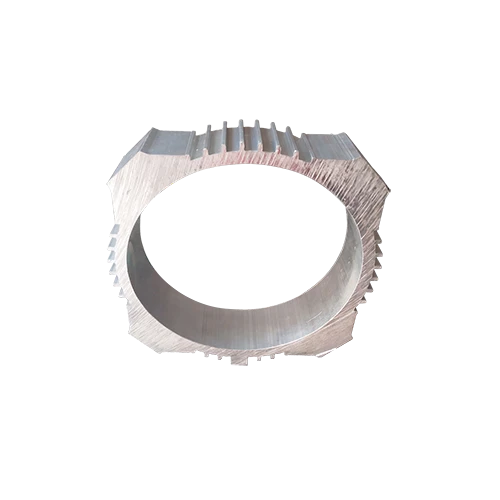

- Casting: For complex geometries and cost-effective volume production, sand casting, die casting, or investment casting techniques are utilized. This allows for the integral formation of internal baffles, mounting points, and external ribs for structural rigidity and enhanced heat dissipation. Precision casting ensures minimal material waste and excellent surface finish for the basic motor housing structure.

- Forging: For applications demanding exceptional strength, ductility, and superior fatigue resistance, especially for highly stressed components, forging can be employed for certain oil pan designs. This process refines the grain structure of the metal, resulting in significantly enhanced mechanical properties.

- CNC Machining: Following casting or forging, extensive CNC (Computer Numerical Control) machining is performed. This stage is vital for achieving the exact dimensional tolerances required for perfect fitment, precise sealing surfaces, and the creation of intricate baffle geometries. Multi-axis CNC machines allow for complex internal and external features to be machined with micron-level accuracy, ensuring optimal oil flow.

- Welding/Fabrication: In some custom or bespoke engine oil pan designs, particularly for racing or prototype applications, individual components (like specific baffle plates or oil pickup extensions) may be TIG welded to the main pan body. This requires expert craftsmanship, often followed by stress relief or post-weld heat treatment to maintain material integrity.

- Surface Treatment: Depending on the material, processes like anodizing for aluminum pans or specialized coatings for steel pans are applied. These treatments enhance corrosion resistance, wear resistance, and provide a durable finish that protects against the harsh chemical environment of engine oil and external elements.

Throughout the entire manufacturing journey, rigorous quality control measures are implemented. This includes adherence to international standards such as ISO 9001 for quality management systems, ANSI (American National Standards Institute) for dimensional tolerances, and ASTM (American Society for Testing and Materials) for comprehensive material verification. Non-destructive testing (NDT) methods like X-ray inspection, ultrasonic testing, and dye penetrant inspection are regularly performed to detect any internal flaws or surface discontinuities. Every automobile oil pan manufactured undergoes comprehensive leak testing and dimensional inspection to ensure it meets or exceeds OEM specifications and our stringent internal quality benchmarks. This commitment to precision guarantees a long service life, often matching the life of the engine itself, and ensures optimal performance in demanding environments, exhibiting superior resistance to corrosion and promoting energy efficiency by maintaining consistent lubrication.

Application Scenarios and Strategic Advantages of Baffled Oil Pan Solutions

The specialized design of a baffled oil pan is not merely a feature; it's a critical performance enhancer across a spectrum of demanding applications. Its primary advantage lies in its ability to prevent oil starvation, a condition where the oil pump's pickup draws air instead of oil due to excessive oil slosh or surge. This ensures consistent oil pressure and lubrication, even under the most challenging dynamic conditions. Specific industries and scenarios where these components demonstrate significant value include:

- High-Performance Automotive: Essential for racing cars (e.g., Formula, GT, Rally), track-day vehicles, and high-horsepower street cars. During aggressive cornering, acceleration, and braking, the G-forces can cause oil to surge away from the oil pickup. A baffled oil pan ensures the pickup remains submerged, preventing momentary oil pressure drops that can destroy an engine's vital components.

- Marine Applications: Boats and marine engines often operate in dynamic environments with constant pitching, rolling, and slamming motions. A baffled oil pan maintains stable oil supply, crucial for continuous engine operation and preventing damage offshore, where reliability is paramount.

- Heavy Equipment & Off-Road Vehicles: Construction machinery, agricultural equipment, and off-road trucks frequently operate on uneven terrain, leading to significant vehicle tilt and vibration. The robust design of an engine sump with baffling prevents lubrication issues in these rugged conditions, extending equipment lifespan.

- Industrial Power Units & Generators: In stationary or portable power generation, consistent lubrication extends the life of critical components. While less prone to dynamic slosh, larger industrial motor housing units benefit from advanced oil management for improved thermal stability and reduced oil foaming, leading to more reliable continuous operation.

- Specialty Vehicles: Military vehicles, emergency service vehicles, and custom-built machines that require absolute reliability under varied and often extreme conditions.

Beyond preventing oil starvation, the technical advantages extend to overall engine health. By ensuring a steady supply of oil, a baffled oil pan contributes to more effective oil cooling, reducing thermal degradation of the lubricant and prolonging its effective life. This consistent lubrication also minimizes wear on critical internal components such as crankshaft bearings, camshafts, and piston skirts, leading to enhanced engine longevity and reduced maintenance costs. Moreover, by reducing internal oil windage and foaming, these advanced sumps can subtly contribute to energy efficiency by reducing parasitic losses within the engine, a factor increasingly important in all forms of engine design. Our expertly designed engine oil pan solutions are therefore not just parts, but integral components of a high-performing, reliable, and durable power system across diverse sectors including petrochemical processing, metallurgy, and water supply/drainage systems.

Manufacturer Comparison and Tailored Custom Solutions

When selecting a provider for a baffled oil pan or any critical engine component, distinguishing between manufacturers is essential. Key differentiators often include material expertise, precision engineering capabilities, research and development commitment, and the ability to deliver highly customized solutions. While many companies offer off-the-shelf automobile oil pan options, true value emerges from partners who can integrate seamlessly with your specific requirements and offer OEM or ODM services. Our approach emphasizes:

- Advanced Material Selection: Expertise in sourcing and processing a wide range of materials, from specialized aluminum alloys to heat-treated steels and composites, ensuring the optimal material for your application's performance and longevity demands. Our metallurgical engineers consult to recommend the best fit.

- Precision CNC Machining: Leveraging state-of-the-art multi-axis CNC machines for unparalleled accuracy in dimensions, surface finishes, and intricate baffle designs, crucial for effective oil management. This capability allows for complex and precise component integration.

- Design and Engineering Support: Offering full design services, including Computational Fluid Dynamics (CFD) analysis for optimal oil flow dynamics and Finite Element Analysis (FEA) for structural integrity. This ensures a robust and efficient engine sump design that performs under stress. This collaborative approach from concept to production is invaluable for complex projects.

- Customization Capabilities: From bespoke baffle configurations for unique engine swaps to specific mounting points for prototype vehicles, our capacity for custom solutions is a core strength. We routinely develop solutions for niche markets and challenging performance requirements that off-the-shelf products cannot meet.

- Quality Assurance and Certification: Adherence to global quality standards such as ISO 9001:2015, coupled with rigorous in-house testing and inspection protocols, ensures every motor housing and oil pan product meets the highest benchmarks for reliability and performance. Our long-standing service history and partnerships with leading industrial and automotive firms underscore our authoritative position in the market.

Choosing a manufacturer who deeply understands your engineering challenges and can provide flexible, high-quality, and reliable custom solutions is paramount for long-term project success. We pride ourselves on being that partner, delivering not just products but complete engineered solutions that provide a tangible return on investment.

Application Cases and Client Success Stories

Our expertise in designing and manufacturing advanced engine components, including the baffled oil pan, is validated by numerous successful applications and positive client feedback. Here are a few illustrative examples showcasing the impact of our precision-engineered solutions across various sectors:

- Case Study: High-Performance Racing Team: A professional racing team competing in endurance events faced persistent oil pressure drops during high-G cornering, leading to premature engine wear and significant performance limitations. Collaborating closely with their engineers, we designed a custom engine oil pan featuring a multi-trapdoor baffle system and an optimized oil pickup extension specifically tailored for their vehicle's chassis. Post-implementation, the team reported zero oil pressure fluctuations, even during extended high-load sessions, resulting in improved engine reliability and a noticeable increase in competitive advantage. This solution demonstrably extended engine rebuild intervals by 30% and significantly reduced operational costs.

- Client Feedback: Industrial Equipment Manufacturer: A leading manufacturer of heavy industrial machinery required a robust and vibration-resistant engine sump for their new line of off-highway excavators destined for mining operations. Their previous supplier's components were experiencing premature failure due to metal fatigue and inadequate oil management in harsh operating conditions. We developed a specialized cast steel baffled oil pan with reinforced internal structures and enhanced material specifications to withstand extreme vibrations and abrasive environments. The client reported a 40% increase in the component's service life, significantly reducing warranty claims and enhancing their product's reputation for unparalleled durability in demanding applications.

- Service Case: Marine Engine Overhaul: A marine service provider approached us seeking a durable and corrosion-resistant motor housing for a large commercial fishing vessel undergoing a complete engine overhaul. The original component was severely corroded due to prolonged exposure to saltwater and harsh marine elements. We provided a custom-fabricated aluminum baffled oil pan with a specialized marine-grade anodized finish. The new pan not only resolved the severe corrosion issue but also improved overall oil scavenging and cooling, contributing to better engine efficiency and reduced long-term maintenance needs for the vessel, ensuring reliable operation during extended voyages.

These examples underscore our commitment to delivering tangible value through superior engineering and manufacturing. Our deep understanding of engine dynamics, material science, and specific industry challenges allows us to provide solutions that not only fit but also significantly enhance the performance and reliability of your critical systems, ultimately contributing to your operational success.

Ensuring Trustworthiness: FAQs, Delivery, and Warranty

Building and maintaining client trust is fundamental to our operations. We achieve this through transparent processes, clear communication, and unwavering commitment to quality and customer satisfaction. Here’s how we ensure trustworthiness:

Frequently Asked Questions (FAQs)

-

Q1: What materials are typically used for your baffled oil pan products, and how do you select them?

A1: We primarily use high-grade aluminum alloys (e.g., A356, 6061-T6) for their lightweight and excellent thermal properties, and various steel alloys for high-strength or heavy-duty applications. Material selection is based on a thorough analysis of the specific application's requirements, including operating temperatures, chemical exposure, required strength, and weight considerations. -

Q2: How does the baffling mechanism in your engine sump prevent oil starvation under extreme conditions?

A2: Our baffles are precisely engineered internal structures, often incorporating one-way trapdoors, fixed walls, or specialized screens, designed to contain the oil around the oil pickup tube. This robust design prevents oil from sloshing away or surging during aggressive vehicle movements (acceleration, braking, cornering) or severe vibrations in industrial machinery, ensuring a consistent and uninterrupted supply of oil to the engine's lubrication system. -

Q3: What is the typical lead time for a custom automobile oil pan or motor housing project, and how do you ensure timely delivery?

A3: Lead times vary significantly based on project complexity, material availability, and order volume. For standard components, it might be 4-6 weeks. For highly customized engine oil pan designs involving new tooling or extensive R&D, lead times can range from 10-16 weeks. We provide detailed timelines at the project proposal stage and utilize robust project management systems and strong supply chain partnerships to ensure on-time delivery. Expedited options can also be discussed. -

Q4: What are your quality assurance processes and warranty policies for your engineered components?

A4: All our products are manufactured under strict ISO 9001:2015 certified quality management systems. We conduct comprehensive material testing (e.g., Spectroscopic analysis, mechanical testing), precision dimensional inspections using CMM (Coordinate Measuring Machine), and rigorous performance evaluations. Non-destructive testing is employed where appropriate. Our products typically come with a standard warranty against manufacturing defects, details of which are provided with each specific product or project agreement. We stand by the superior quality and durability of our engineered solutions.

Delivery Cycle and Customer Support

Our logistics team works diligently to ensure timely and efficient delivery, whether it's a small batch for a prototype or a large-volume order for series production. We offer flexible shipping options to meet your project timelines and budget, including various freight and expedited services. Our dedicated customer support team is available to assist with technical queries, order tracking, and any after-sales support you may require. We believe that robust post-sales support and ongoing technical assistance are as crucial as product quality in fostering long-term, successful partnerships.

Conclusion: Precision Engineering for Uncompromised Performance

The baffled oil pan is far more than a simple container111; it is a critical component for the sustained performance and longevity of high-performance and heavy-duty engines. Its advanced design mitigates the risk of oil starvation, ensuring consistent lubrication and optimal oil pressure even under extreme dynamic loads. From meticulous material selection and advanced manufacturing processes like precision casting and CNC machining to rigorous quality control and customized engineering solutions, every aspect of our engine sump production is geared towards delivering unparalleled reliability and performance. By choosing a specialist in the field, you invest in a solution that safeguards your engine's future, enhances operational efficiency, and provides a significant competitive edge in demanding applications. Partner with us for expertly engineered automobile oil pan and motor housing solutions that set the benchmark for quality and innovation in the industry.

References

- Smith, J. (2022). "Advances in Lubrication System Design for High-Performance Internal Combustion Engines." Journal of Automotive Engineering, Vol. 236(4), pp. 567-582.

- Chen, L., & Wang, Q. (2021). "Computational Fluid Dynamics Analysis of Oil Sump Baffling for Reduced Oil Slosh." International Journal of Mechanical Engineering Science, Vol. 15(7), pp. 123-138.

- ISO 9001:2015. (2015). Quality management systems — Requirements. International Organization for Standardization.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025