Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

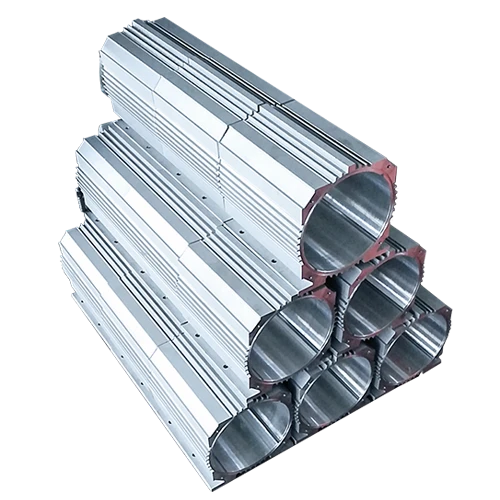

aluminum motor housing

The Advantages of Aluminum Motor Housings

Aluminum motor housings have gained significant popularity across various industries due to their exceptional properties and numerous advantages. As manufacturers continuously seek materials that enhance performance while reducing weight and costs, aluminum has emerged as a top contender. This article explores the benefits of using aluminum for motor housings, emphasizing its mechanical, thermal, and economic advantages.

The Advantages of Aluminum Motor Housings

Thermal conductivity is another critical property that makes aluminum an ideal choice for motor housings. Aluminum effectively dissipates heat, ensuring that the motor operates within safe temperature ranges. This attribute is crucial for maintaining performance and extending the lifespan of the motor. Overheating can lead to catastrophic failures, so effective thermal management is a fundamental requirement in motor design. Aluminum's ability to conduct heat away from critical components enhances reliability and efficiency.

aluminum motor housing

Moreover, aluminum exhibits excellent corrosion resistance, especially when treated with protective coatings or anodization. This characteristic is vital in environments where motors may be exposed to moisture, chemicals, or harsh weather conditions. The longevity of motor housings is essential for reducing maintenance costs and ensuring continuous operation. By using aluminum, manufacturers can prolong the life of motors and decrease the frequency of replacements, resulting in significant cost savings.

Another economic advantage of aluminum is its recyclability. With growing environmental concerns, many industries are prioritizing sustainable practices. Aluminum can be easily recycled without losing its inherent properties, making it an eco-friendly choice for motor housings. This not only reduces waste but also lessens the environmental impact associated with the production of new materials. By integrating recyclable materials like aluminum into their products, manufacturers align themselves with modern sustainability goals.

Additionally, the manufacturing processes for aluminum, such as extrusion and casting, allow for better design flexibility and the incorporation of complex geometries. This capability is particularly beneficial in designing motors with specific performance criteria. Manufacturers can create lightweight, intricate shapes that optimize airflow and cooling while providing necessary structural support.

In conclusion, aluminum motor housings offer a multifaceted array of advantages, including a favorable strength-to-weight ratio, excellent thermal conductivity, corrosion resistance, recyclability, and design flexibility. These properties not only contribute to enhanced motor performance but also support sustainability initiatives within the industry. As technology advances and the demand for efficient, long-lasting motor solutions grows, aluminum will likely continue to play a pivotal role in the evolution of motor housing design.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025