Mobile:+86-311-808-126-83

Email:info@ydcastings.com

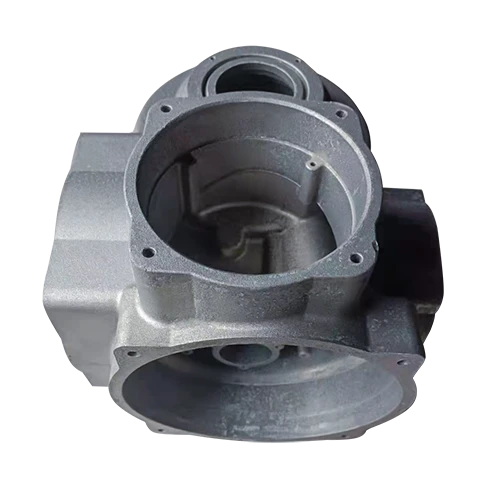

aluminium sand casting

The Process and Advantages of Aluminium Sand Casting

Aluminium sand casting is a widely used manufacturing process that transforms molten aluminium into functional metal components through the utilization of sand molds. This technique is particularly valued for its versatility and cost-effectiveness, making it a preferred choice across various industries, including automotive, aerospace, and consumer goods.

Understanding the Process

The aluminium sand casting process begins with the creation of a mold. This mold is typically made from a mixture of sand, clay, and water, which is compacted to form the desired shape. The sand used is often silica sand due to its durability and heat resistance. The first step involves creating a pattern, usually produced from metal or plastic, which is used to shape the sand.

Once the pattern is made, the sand is packed around it to form the mold. A very accurate replication is crucial, as any imperfection in the mold can lead to defects in the final casting. After the mold is formed, the pattern is removed, leaving a cavity that represents the desired final shape of the component.

Next, molten aluminium is poured into the mold. The aluminium is heated to its melting point—around 660°C (1220°F)—and is usually sourced from recycled materials, making this process environmentally friendly. Once the molten metal is poured, it fills the cavity and takes the shape of the mold. After the aluminium cools and solidifies, the mold is broken apart to extract the casting.

Advantages of Aluminium Sand Casting

1. Cost-Effectiveness One of the primary advantages of aluminium sand casting is its low cost. Unlike other casting processes that may require expensive equipment or complex setup, sand casting can be performed with relatively inexpensive materials. This affordability makes it particularly appealing for both small and large production runs.

aluminium sand casting

2. Versatility Aluminium sand casting can accommodate a wide range of sizes and shapes, from small intricate components to large heavy parts. This process allows manufacturers to create custom shapes, making it suitable for various applications.

3. Recycling Benefits The use of recycled aluminium in sand casting not only reduces raw material costs but also minimizes environmental impact. This sustainable aspect of salvaging and reusing materials has become increasingly important in contemporary manufacturing practices.

4. Thermal and Corrosion Resistance Cast aluminium exhibits excellent thermal properties, making it ideal for applications that require heat dissipation. Additionally, aluminium is naturally resistant to corrosion, increasing the longevity of the products manufactured through this method.

5. Surface Finish and Detail Sand casting can achieve a satisfactory surface finish and complex geometrical details, especially when high-quality sand and modernization techniques are employed in the process. Advanced methods, such as 3D printing for patterns, can enhance the precision and reduce lead times.

Challenges of Aluminium Sand Casting

Despite its numerous advantages, aluminium sand casting does have its challenges. Issues such as sand inclusion, which can lead to surface irregularities, and difficulties in controlling the dimensions of the casting may arise. Moreover, the labor-intensive nature of preparing molds can increase the time required for production.

Conclusion

Aluminium sand casting remains a significant method in the manufacturing industry due to its cost-effectiveness, versatility, and sustainability. As technology advances, the efficiency and capabilities of this casting process continue to improve, making it an ideal choice for producing a wide range of components. With its environmental benefits and ability to create complex shapes, aluminium sand casting is poised to be an integral part of modern manufacturing practices.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025