Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

aluminium alloy investment casting

Aluminium Alloy Investment Casting A Modern Manufacturing Marvel

Aluminium alloy investment casting is a sophisticated manufacturing process that has gained immense popularity in various industries due to its ability to produce complex geometries with high precision. This technique has become a preferred method for fabricating components in sectors such as aerospace, automotive, electronics, and medical devices, thanks to the unique properties of aluminium alloys and the inherent advantages of the investment casting process.

What is Aluminium Alloy Investment Casting?

Investment casting, often referred to as lost-wax casting, involves creating a wax pattern of the desired component, which is then coated with a ceramic shell. Once the ceramic shell hardens, the wax is melted away, leaving a hollow mold. Molten aluminium alloy is then poured into this mold to create the final part. Given the versatility of aluminium alloys, manufacturers can choose from a wide range of compositions tailored to meet specific mechanical properties and environmental conditions.

Advantages of Aluminium Alloy Investment Casting

1. Precision and Complexity Investment casting allows for intricate designs with high dimensional accuracy that may be difficult or impossible to achieve with other manufacturing methods. Thin walls, fine details, and complex internal geometries can be produced, making it ideal for applications that demand high precision.

2. Material Efficiency The investment casting process generates minimal waste compared to traditional machining processes. This is especially important in industries where material costs are high, as it maximizes the use of the available aluminium.

3. Superior Surface Finish Parts produced via investment casting typically have a smoother surface finish than those manufactured through other methods. This quality reduces the need for extensive post-processing, saving time and costs in production.

4. Strength-to-Weight Ratio Aluminium alloys are known for their excellent strength-to-weight ratios. This characteristic is particularly advantageous in applications like aerospace and automotive where lightweight components contribute to overall performance and fuel efficiency.

aluminium alloy investment casting

5. Corrosion Resistance Many aluminium alloys offer high resistance to corrosion, making them suitable for use in harsh environments. This property is crucial for components exposed to moisture, chemicals, and extreme temperatures.

Applications of Aluminium Alloy Investment Casting

Given its unique attributes, aluminium alloy investment casting finds applications in numerous fields

- Aerospace Aircraft components, such as brackets, housings, and engine parts, require both lightweight materials and high strength. Investment casting allows manufacturers to achieve this optimization while meeting stringent regulatory standards.

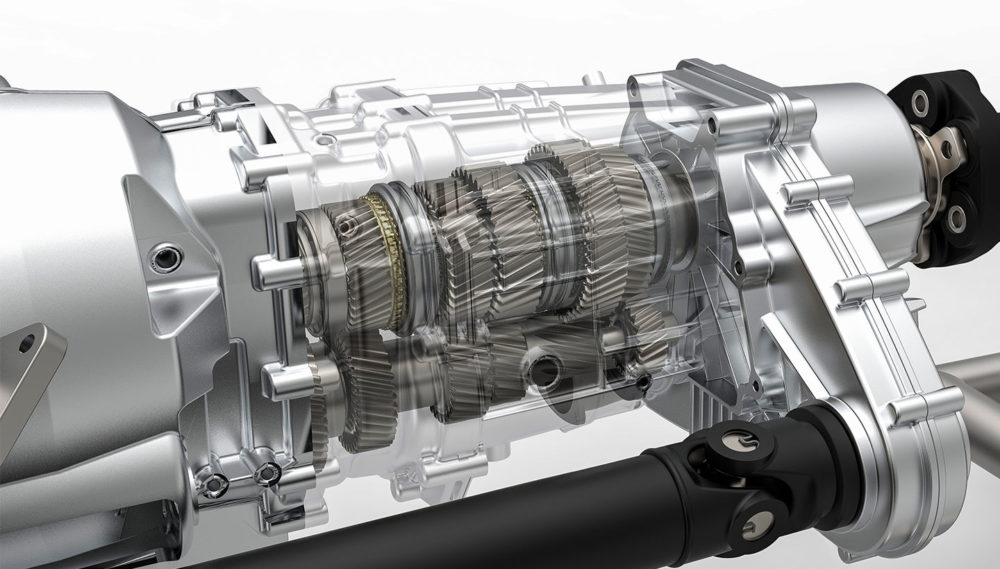

- Automotive The automotive industry benefits from the ability to produce intricate parts for engines, transmission casings, and suspension systems, helping manufacturers create vehicles that are both lightweight and durable.

- Electronics With the rise of miniaturization in electronics, the demand for finely engineered components has surged. Investment casting is ideal for creating cases and housings that are both functional and aesthetically pleasing.

- Medical Devices Components like surgical instruments and implants require not only precision but also biocompatibility and ease of sterilization. Aluminium alloys processed through investment casting meet these needs efficiently.

Conclusion

Aluminium alloy investment casting stands as a testament to the advancements in modern manufacturing techniques. Its ability to combine precision, material efficiency, and versatility makes it an invaluable process across various industries. As technology continues to evolve, the applications of aluminium investment casting are bound to expand, leading to lighter, stronger, and more intricate components that push the boundaries of design and functionality. This innovative method not only meets the demands of today’s economy but also paves the way for future advancements, setting the stage for a new era of manufacturing excellence. In the quest for efficiency and sustainability, aluminium alloy investment casting shines brightly, making it a keystone of modern production practices.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025