Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Aluminium Metal Casting Solutions with Rapid Die Production

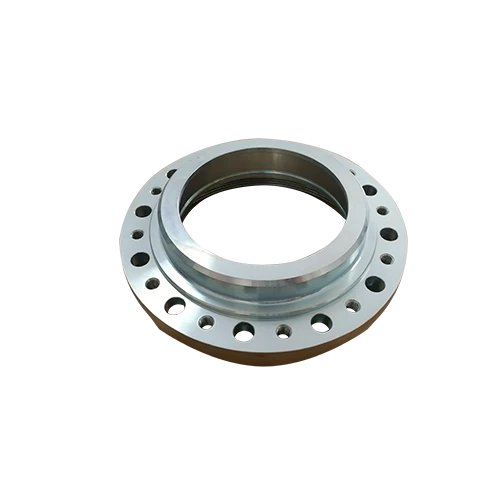

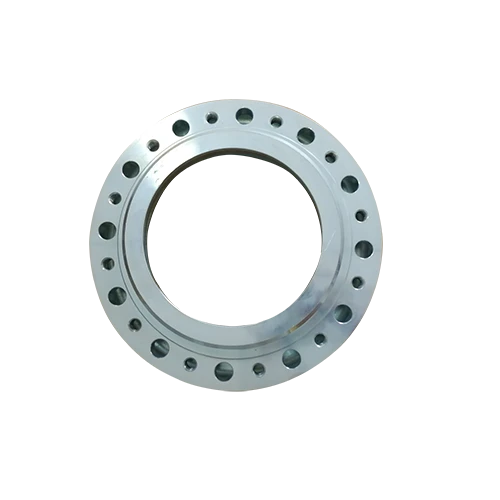

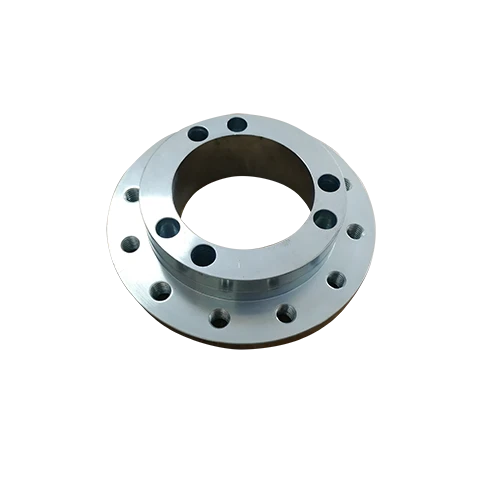

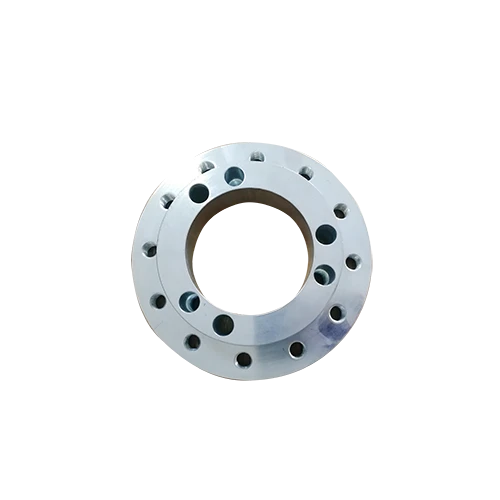

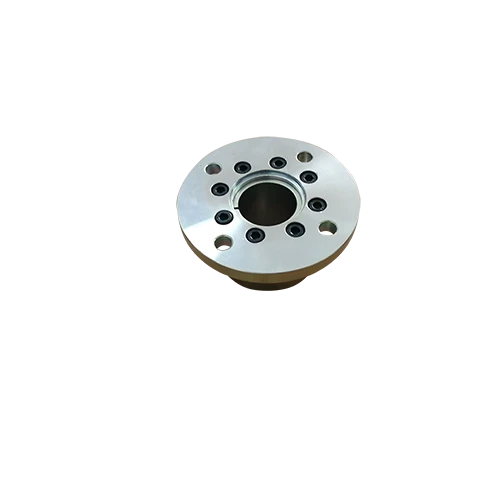

Aluminium metal casting is revolutionizing how manufacturers deliver precision-engineered components for modern industries. Integrating mature metal castings methods, green sand metal casting innovations, and advanced aluminum die casting processes, this approach is the bedrock for reliable products like flanges. In this article, we explore the manufacturing ecosystem, technical parameters, industry trends, and application advantages of aluminium cast flanges—including a practical dissection of aluminium metal casting for flange components.

1. Industry Overview: Trends in Aluminium Metal Casting

- Global Market Expansion: Aluminium metal casting market is projected to reach $86.5 billion by 2030 (CAGR: 5.1%), driven by automotive, petrochemical, and infrastructure growth.[1]

- Green Sand Metal Casting: Over 42% of global non-ferrous castings are now produced using green sand, reflecting cost-effectiveness and eco-friendly requirements.

- Technological Upgrades: Adoption of fully automated die-casting lines and Industry 4.0 control increases yield rate and precision.

- Standardization: Adherence to international standards (ISO, ANSI, ASTM) enhances consistency, traceability, and interchangeability in components.

2. Aluminium Metal Casting Process Flow for Flange Manufacturing

Select aluminium alloy for casting according to mechanical & corrosion requirements.

Induction furnace melts alloy at 660–750°C, degassing for purity.

Choice: green sand metal casting (sand mold) or permanent mold/die casting (steel die).

Molten alloy is poured, solidifies in the mold (Time: 1–15 min).

Castings removed, cleaned, and prepped for machining.

Machining bolt holes, faces, threads (tolerance: up to ±0.02 mm).

100% dimension check, X-ray, pressure tests per ISO/ANSI.

Anodizing/powder coating for extra corrosion resistance.

3. Key Technical Specifications: Aluminium Cast Flange (Product Link)

| Property | Parameter | Standard/Typical Value | Relevance |

|---|---|---|---|

| Material | Aluminium Alloy (A356, 6061, 6082) | Si: 6.5–7.5%, Mg: 0.3–0.45%, Al: Bal. | Optimized for strength/corrosion |

| Manufacturing Process | Green Sand Casting / Die Casting + CNC | Porosity ≤ 2.5%; tight tolerance ±0.02 mm | High dimensional accuracy |

| Nominal Pressure (PN) | #150, #300, #600, #900, #1500 | 2.0–25.0 MPa | Industrial piping compatible |

| Size Range | DN15–DN1200 (½"–48") | Thickness: 8–55 mm | Application flexibility |

| Surface Protection | Anodized / Powder Coated | Salt-spray ≥ 1200 hours | Enhanced anti-corrosion |

| Inspection Standard | ISO 9001/ANSI B16.5/EN 1092-1 | 100% hydro-test, X-ray | Quality guarantee |

| Service Life | ≥ 35 years | At pH 6–9, -30°C~120°C | Long-term stability |

4. Data Visualization: Aluminium vs. Stainless Steel Casting Flanges

| Feature | Aluminium Alloy Casting | Stainless Steel Casting |

|---|---|---|

| Density (g/cm3) | 2.7 | 7.8 |

| Tensile Strength (MPa) | 220–320 | 500–750 |

| Corrosion Resistance | Excellent (with anodizing) | Excellent (natural passivation) |

| Weight Reduction | Yes (up to -65%) | No |

| CNC Machinability | High | Medium |

| Cost Index | 70 | 100 |

| Common Application | HVAC, water supply, structure | Chemical, high pressure |

5. Application Scenarios & Case Studies

- Oil & Gas: Lightweight flanges enable faster installation and reduced transportation costs.

- Municipal Water: Corrosion-resistant aluminium metal casting flanges ensure ≥30 years of service, especially in chlorine-rich zones.

- HVAC & Construction: Weight reduction (by up to 65% vs. steel) eases support burden and energy costs.

- Chemical Processing: Anodized/powder-coated aluminium flanges resist aggressive chemicals, reducing downtime.

- Renewable Energy: Fatigue-resistant flanges for solar/wind installations due to cyclic load resistance.

- PetroChina (2023 Retrofit): Utilized 13,000+ aluminium cast flanges in pipeline upgrades. → "Since deployment, annual maintenance costs dropped 19%, and installation time per flange was cut by 44% compared to stainless steel alternatives."

- Saudi Water Authority: Deployed aluminium die cast flanges in desalination plants. → Reported zero corrosion failures after five years in high-salt atmosphere (salt-spray test: ≥1200h, EN ISO 9227:2017).

- France Urban District Heating Project: Flanges passed ANSI B16.5 leak-proof test and supported 15% lighter designs, reducing supporting bracket budget.

- Manufacturer certified by ISO 9001:2015, products passed ANSI B16.5, EN 1092-1 tests.

- Strategic supply agreements with SINOPEC, Veolia Water, GEA Group.

- Annual output: 3 million+ flanges, quality traceable for 10 years after delivery.

6. Manufacturer Comparison: Flange Solutions From Leading Suppliers

| Factory | Material Expertise | Annual Output (pcs) | Certifications | Lead Time (days) | Custom Design |

|---|---|---|---|---|---|

| Y&D Castings | Aluminium, Stainless Steel, Ductile Iron | 3,000,000+ | ISO 9001, EN 1092-1 | 12~22 | Yes (OEM/ODM, drawings) |

| Germany L.M. AG | Aluminium, Carbon Steel | 950,000 | ISO 14001, DIN 2501 | 20~30 | Yes (limited) |

| TN Steel India | Stainless Steel, Cast Iron | 780,000 | API 6A, ISO 9001 | 18~29 | No (standard only) |

| Italy O.F. Spa | Aluminium, Bronze | 210,000 | EN 10204, PED | 28~35 | Yes |

7. Custom Flange Solutions: From Consultation to Delivery

- Project Consultation: Detailed engineering review, free sample design feasibility analysis.

- Material Selection: Choose optimal aluminium alloy for casting based on customer’s usage, temp. profile, and media.

- Casting Prototyping: 3D printed pattern for sample approval in 5–7 days.

- Precision Machining: Automated CNC, CMM verification.

- Comprehensive Testing: Hydro-static, X-ray, tensile & corrosion tests (with full report).

- Packing & Logistics: Custom crates, multi-lingual marking, tracking for global delivery.

8. FAQ: Advanced Aluminium Metal Casting for Flange Applications

9. Customer Support & Guarantees

- Support: 24/7 technical helpdesk, installation guides, and on-site support available globally.

- Response Time: Quotation in 12 hours, detailed production schedule on order.

- Warranty: All aluminium metal casting flanges are covered by an 18-month quality warranty after delivery.

- Traceability: Each product shipped with QR trace code linking to batch test report.

10. References & Further Reading

-

[1] "Aluminium in the Global Metal Casting Market",

Foundry-Planet Industry Report (2024) -

"Mechanical Properties and Quality Control in Cast Aluminium Flange Manufacturing" –

ScienceDirect, J. of Manufacturing Processes (2021) - ANSI Standard B16.5 for Flanges, ASME Official

-

"Quality Inspection and Corrosion Resistance of Aluminium Cast Flanges",

Forging Industry Association White Paper - Forum: Eng-Tips.com Metal Casting Forum

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025