Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Advanced Connector Castings - Hebei Yuanda Trade Co., Ltd.|Precision, Durability, Innovation

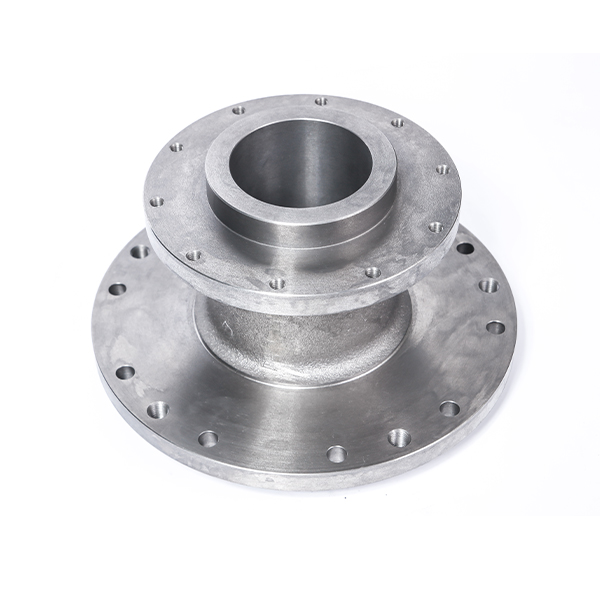

Connector castings play a critical role in the performance and reliability of pump systems, ensuring seamless integration between components and pipes. As a leading manufacturer in the industry, Hebei Yuanda Trade Co., Ltd. (Welcome To Hebei Yuanda Trade Co., Ltd.) offers high-quality connector castings designed to meet the rigorous demands of modern pumping equipment. This article explores the features, technical specifications, applications, and company background of these essential components, while also highlighting the importance of precision engineering and quality standards in the field.

Product Overview: Connector Castings for Pump Systems

Connector castings are fundamental parts of pump equipment, serving as the critical interface between various components or piping systems. These castings are typically manufactured from robust metal materials such as cast iron (GG25), stainless steel, or aluminum alloys. The selection of materials and the design of these castings directly influence the performance, stability, and longevity of pumping systems. High-quality connector castings ensure optimal operation, minimize the risk of leakage or damage, and enhance the overall efficiency of pump equipment.

One of the key advantages of these connector castings is their ability to withstand harsh operating conditions. Factors such as corrosion resistance, wear resistance, and pressure tolerance are meticulously considered during the design and manufacturing process. This ensures that the castings can perform reliably in diverse environments, from industrial water treatment plants to chemical processing facilities.

Key Features and Advantages

High Shape Accuracy

The precision of connector castings is paramount, as it directly impacts the sealing performance of pump systems. Advanced casting techniques, including the use of fine molds and state-of-the-art equipment, ensure that the finished products achieve high shape accuracy. This level of precision is essential for maintaining the integrity of pump seals, reducing the likelihood of fluid leakage, and extending the service life of the equipment.

Dimensional Accuracy

Dimensional accuracy refers to the degree to which the final casting matches the design specifications. For pump components, this is a critical quality indicator, as even minor deviations can compromise the pump's performance and installation. Hebei Yuanda Trade Co., Ltd. employs advanced production technologies to ensure that each casting meets stringent dimensional requirements, enabling seamless integration with other system components.

Superior Surface Quality

The surface finish of connector castings is another vital factor in their performance. High-quality castings are free from defects such as sand holes or air holes, which can lead to costly repairs and reduced efficiency. A smooth surface not only enhances the aesthetic appeal of the component but also improves the pump's operational efficiency and reduces the failure rate. This is achieved through rigorous quality control measures and the use of advanced casting techniques.

Advanced Production Technology

Hebei Yuanda Trade Co., Ltd. utilizes resin sand casting technology to produce connector castings efficiently and cost-effectively. This method allows for mass production while maintaining high-quality standards. Compared to traditional casting methods, resin sand casting reduces the need for subsequent processing steps, lowers energy consumption, and minimizes labor costs. The result is a product that combines superior performance with economic efficiency.

Material Selection for Optimal Performance

The choice of materials for connector castings is critical to their performance. Cast iron (GG25) is a popular option due to its excellent strength and durability. Stainless steel offers enhanced corrosion resistance, making it suitable for applications involving aggressive chemicals or high-temperature environments. Aluminum alloys, on the other hand, provide a lightweight yet robust solution, ideal for applications where weight reduction is a priority.

Technical Specifications Table

| Feature | Details |

|---|---|

| Product Name | Connectors |

| Weight Range | 5-50kg |

| Material | GG25-Cast Iron, Stainless Steel, Aluminum Alloys |

| Casting Process | Resin Sand Casting |

| Shape Accuracy | High precision, minimal deviation from design specifications |

| Surface Quality | Smooth, free from sand holes or air holes |

| Corrosion Resistance | Dependent on material (e.g., stainless steel for high corrosion resistance) |

Applications of Connector Castings

Connector castings are widely used in various industries where reliable pumping systems are essential. Some common applications include:

- Water Treatment Plants: Ensuring efficient water circulation and filtration systems.

- Chemical Processing: Handling corrosive fluids with high durability and resistance.

- Industrial Manufacturing: Supporting machinery that requires precise fluid control.

- HVAC Systems: Facilitating the movement of coolant or heating fluids.

Company Background: Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. (Welcome To Hebei Yuanda Trade Co., Ltd.) is a reputable manufacturer specializing in high-quality castings for industrial applications. With a commitment to innovation and excellence, the company has established itself as a trusted supplier of connector castings and other critical components. Their expertise in resin sand casting and precision engineering ensures that their products meet the highest standards of performance and reliability.

Hebei Yuanda Trade Co., Ltd. serves a global clientele, providing tailored solutions for diverse industries. Their dedication to quality control and customer satisfaction is reflected in the consistent performance of their products. For more information about their offerings, visit the product page.

The Role of Standards in Casting Technology

Ensuring the quality and reliability of connector castings requires adherence to industry standards. Organizations like the National Institute of Standards and Technology (NIST) play a crucial role in developing and maintaining measurement standards that underpin the manufacturing process. While the exact NIST page referenced in the context could not be found, NIST's work in metrology and materials science is foundational to the advancement of casting technologies. Their research into precision measurements and material properties directly influences the development of high-quality castings.

By aligning with standards set by institutions like NIST, manufacturers such as Hebei Yuanda Trade Co., Ltd. can ensure their products meet the rigorous demands of modern industrial applications. This commitment to standardization not only enhances product performance but also fosters trust among customers and industry partners.

Reference: National Institute of Standards and Technology (NIST)

Conclusion

Connector castings are indispensable components in pump equipment, and their quality directly impacts the efficiency and reliability of the entire system. Hebei Yuanda Trade Co., Ltd. exemplifies the importance of precision engineering, advanced production technologies, and material innovation in delivering high-performance castings. With a focus on shape accuracy, dimensional precision, and surface quality, the company continues to set benchmarks in the industry.

As the demand for reliable and efficient pumping systems grows, the role of connector castings will only become more critical. By adhering to strict quality standards and leveraging cutting-edge technologies, Hebei Yuanda Trade Co., Ltd. is well-positioned to meet the evolving needs of its customers. For more details about their products and services, visit the product page or explore the company website.

Keywords

Impeller: Read More About pumpe impeller

Cap Ends: Read More About pumpe impeller

Impeller on Pump: Read More About pumpe impeller

Pumpe Impeller: Read More About pumpe impeller

Water Pump Impeller: Read More About water pump impeller

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025