Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Exploring the Connection Between A995 and Its Impact on B in Industry Contexts

Understanding the A995% 201B Alloy A Comprehensive Overview

In the ever-evolving landscape of materials science, alloys play a pivotal role in various industries, and among them, A995% 201B stands out due to its unique properties and applications. This article delves into the characteristics, manufacturing processes, and practical applications of the A995% 201B alloy, exploring why it has become a material of choice for engineers and manufacturers alike.

Composition and Properties

A995% 201B is a high-performance alloy primarily composed of aluminum, along with other elements such as copper, manganese, and silicon. The designation A995 indicates its composition is at least 99.5% aluminum, while 201B denotes its specific alloy series. This classification is crucial as it affects the thermal conductivity, strength, and corrosion resistance, which are critical factors in many engineering applications.

One of the standout features of the A995% 201B alloy is its excellent strength-to-weight ratio. This property makes it highly desirable in industries where reducing weight without compromising strength is essential. From the aerospace sector to automotive manufacturing, the ability to construct lighter structures without sacrificing durability significantly enhances overall performance and fuel efficiency.

Additionally, A995% 201B displays superior corrosion resistance compared to conventional aluminum alloys. This resistance is particularly beneficial in environments where exposure to moisture and chemicals is common, such as marine applications or chemical processing plants. The alloy's ability to maintain structural integrity even in harsh conditions ensures longevity and reduces maintenance costs.

Understanding the A995% 201B Alloy A Comprehensive Overview

The manufacturing of A995% 201B involves advanced metallurgical techniques designed to optimize its properties. A common method used is the melting and casting process, where raw materials are melted together in a controlled environment to ensure a uniform composition. Once the alloy is formed, it undergoes processes such as extrusion or forging, which further refine the material's properties through work hardening.

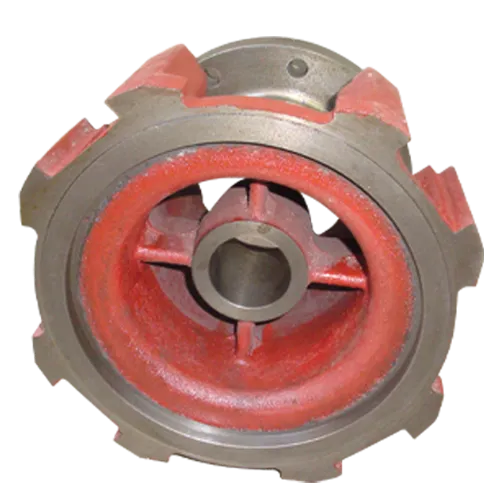

a995 1b

Heat treatment is also a critical step in the production of A995% 201B. This process enhances its mechanical properties by altering the microstructure, leading to increased strength and toughness. Ultimately, the combination of these manufacturing techniques results in a material that is not only robust but also highly workable, allowing for intricate designs and applications.

Applications in Various Industries

The versatility of A995% 201B has led to its widespread use across several industries. In the aerospace sector, it is increasingly employed in the construction of aircraft components, where reducing weight is crucial for fuel efficiency and performance. The automotive industry also benefits from this alloy, especially in manufacturing parts that require high strength and lightweight characteristics, contributing to improved vehicle efficiency.

Furthermore, A995% 201B is used in the construction industry for structural applications. Its corrosion resistance makes it suitable for bridges and buildings exposed to the elements, providing a durable solution that extends the lifespan of infrastructures. Additionally, consumer electronics are another sector utilizing this alloy, as manufacturers seek to create devices that are not only lightweight but also resistant to wear and tear.

Sustainability Considerations

In an age where sustainability is paramount, A995% 201B presents an eco-friendly option. Aluminum alloys can be recycled without losing their properties, making them highly sustainable materials. The recycling process consumes significantly less energy compared to the extraction and processing of raw aluminum, aligning with environmental goals and reducing overall carbon footprints.

Conclusion

In summary, A995% 201B is a remarkable alloy that combines strength, lightweight characteristics, and corrosion resistance, making it a versatile choice across various industries. Its unique properties stem from a precise composition and advanced manufacturing processes that ensure high performance in demanding environments. As industries continue to innovate and prioritize sustainability, A995% 201B is poised to play an increasingly significant role in shaping the future of materials science. Engineers and manufacturers who recognize the benefits of this alloy will undoubtedly lead the charge toward more sustainable and efficient solutions in their respective fields.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025