Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 17, 2025 14:16

Back to list

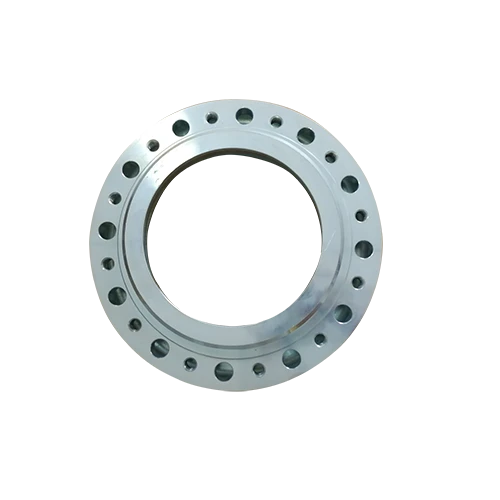

Motor shell housing

The 7.3 compressor housing is an essential component in turbocharged engine systems, pivotal in enhancing engine performance and efficiency. A robust understanding of this component not only benefits automotive enthusiasts but also professionals seeking to maximize engine output and durability.

Moreover, the compressor housing's aerodynamic design plays a significant role in minimizing turbulence and maximizing airflow. Innovations in computational fluid dynamics (CFD) have allowed designers to refine housing shapes to enhance aerodynamic efficiency and reduce lag. In practice, this means that the transitioning of air from the housing to the intercooler and ultimately into the engine is smoother, resulting in quicker spool times and more immediate power delivery. When it comes to maintenance and reliability, the compressor housing often requires minimal direct intervention but is dependent on consistent overall system maintenance to ensure longevity. This includes regular checks for leaks, particularly along seal points where the housing connects with other components, to prevent loss of pressure and subsequent efficiency drops. It’s also critical to ensure that the housing and the turbo system have proper ventilation and lubrication, as overheating and friction can severely degrade system performance and lifespan. In practical applications, especially in heavy-duty and high-performance contexts, upgrading to a performance compressor housing can bring significant benefits. For instance, aftermarket options often provide enhanced durability and optimized flow designs tailored for specific engine outputs. However, it’s essential to pair these upgrades with suitable engine calibration to achieve desired results without risking component stress or engine damage. Ultimately, the 7.3 compressor housing is not just a static component but a dynamic contributor to the overarching efficiency of turbocharged engine systems. It embodies a synthesis of material science, aerodynamic engineering, and mechanical design precision. For those looking to elevate their engine’s performance, a well-chosen compressor housing supported by expert installation and precise tuning can unlock noticeable gains in power, efficiency, and reliability. Whether for commercial vehicles or personal performance enhancement, understanding and optimizing this component is a mark of both professionalism and passion in the field of automotive engineering.

Moreover, the compressor housing's aerodynamic design plays a significant role in minimizing turbulence and maximizing airflow. Innovations in computational fluid dynamics (CFD) have allowed designers to refine housing shapes to enhance aerodynamic efficiency and reduce lag. In practice, this means that the transitioning of air from the housing to the intercooler and ultimately into the engine is smoother, resulting in quicker spool times and more immediate power delivery. When it comes to maintenance and reliability, the compressor housing often requires minimal direct intervention but is dependent on consistent overall system maintenance to ensure longevity. This includes regular checks for leaks, particularly along seal points where the housing connects with other components, to prevent loss of pressure and subsequent efficiency drops. It’s also critical to ensure that the housing and the turbo system have proper ventilation and lubrication, as overheating and friction can severely degrade system performance and lifespan. In practical applications, especially in heavy-duty and high-performance contexts, upgrading to a performance compressor housing can bring significant benefits. For instance, aftermarket options often provide enhanced durability and optimized flow designs tailored for specific engine outputs. However, it’s essential to pair these upgrades with suitable engine calibration to achieve desired results without risking component stress or engine damage. Ultimately, the 7.3 compressor housing is not just a static component but a dynamic contributor to the overarching efficiency of turbocharged engine systems. It embodies a synthesis of material science, aerodynamic engineering, and mechanical design precision. For those looking to elevate their engine’s performance, a well-chosen compressor housing supported by expert installation and precise tuning can unlock noticeable gains in power, efficiency, and reliability. Whether for commercial vehicles or personal performance enhancement, understanding and optimizing this component is a mark of both professionalism and passion in the field of automotive engineering.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS