Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

标题Title6.5TurboDiesel排气歧管-优质性能与耐久性

6.5% Turbo Diesel Exhaust Manifold

Turbo diesel engines have gained immense popularity in the automotive industry due to their efficiency and power. One critical component that significantly impacts engine performance is the exhaust manifold. In this article, we will explore the importance of the 6.5% turbo diesel exhaust manifold, its design, and its role in enhancing engine performance.

Exhaust Manifold Overview

The exhaust manifold is a crucial part of a turbo diesel engine, responsible for collecting exhaust gases from the engine cylinders and channeling them to the turbocharger. The efficiency of the exhaust manifold directly affects the overall performance of the engine. A well-designed manifold can improve exhaust flow, reduce turbo lag, and enhance the engine's responsiveness.

Importance of Turbocharging

Turbocharging is a technology that uses exhaust gases to spin a turbine, which in turn forces more air into the engine's cylinders. This process increases the engine's power output without significantly increasing its size or weight. The 6.5% turbo diesel exhaust manifold is specifically designed to optimize this process, ensuring that exhaust gases are efficiently directed to the turbocharger.

Design Features

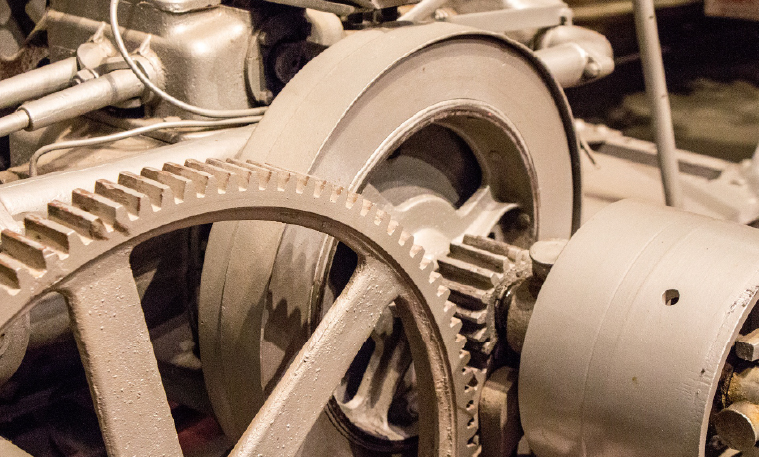

A 6.5% turbo diesel exhaust manifold typically features several key design elements

1. Material Selection The manifold is usually made from high-quality cast iron or stainless steel to withstand high temperatures and resist corrosion. This durability is essential for maintaining performance over time.

2. Runner Design The shape and length of the runners in the manifold play a vital role in exhaust flow. A well-optimized runner design minimizes restrictions and promotes smooth flow, which is crucial for turbocharger efficiency.

3. Heat Management Effective heat dissipation is important to maintain the performance of both the engine and the turbocharger. Many modern manifolds are designed with heat shields or coatings to manage temperatures effectively.

6.5 turbo diesel exhaust manifold

4. Emissions Control The design of the exhaust manifold also impacts the engine's emissions. A well-engineered manifold can help improve the combustion process, resulting in fewer harmful emissions.

Performance Benefits

The advantages of using a high-quality 6.5% turbo diesel exhaust manifold are numerous

- Increased Power By improving exhaust flow, the manifold allows the turbocharger to operate more efficiently, resulting in increased power output.

- Reduced Turbo Lag A well-designed manifold helps to deliver exhaust gases to the turbocharger more rapidly, minimizing lag and providing a more responsive engine.

- Improved Fuel Efficiency Better exhaust flow and turbocharging efficiency often lead to improved fuel economy, making turbo diesel engines more economical in the long run.

- Enhanced Reliability Using high-quality materials and engineering in the manifold design ensures greater reliability and longevity of the engine, reducing maintenance issues over time.

Conclusion

The 6.5% turbo diesel exhaust manifold is a vital component that significantly influences the performance and efficiency of turbo diesel engines. With advancements in design and materials, modern exhaust manifolds provide improved power, reduced turbo lag, and enhanced fuel efficiency. For anyone looking to optimize their turbo diesel engine, investing in a quality exhaust manifold is a step that promises substantial benefits.

By understanding the role of the exhaust manifold and its impact on engine performance, vehicle owners can make informed decisions that lead to better driving experiences and greater overall satisfaction with their turbo diesel engines.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025