Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jan . 21, 2025 01:07

Back to list

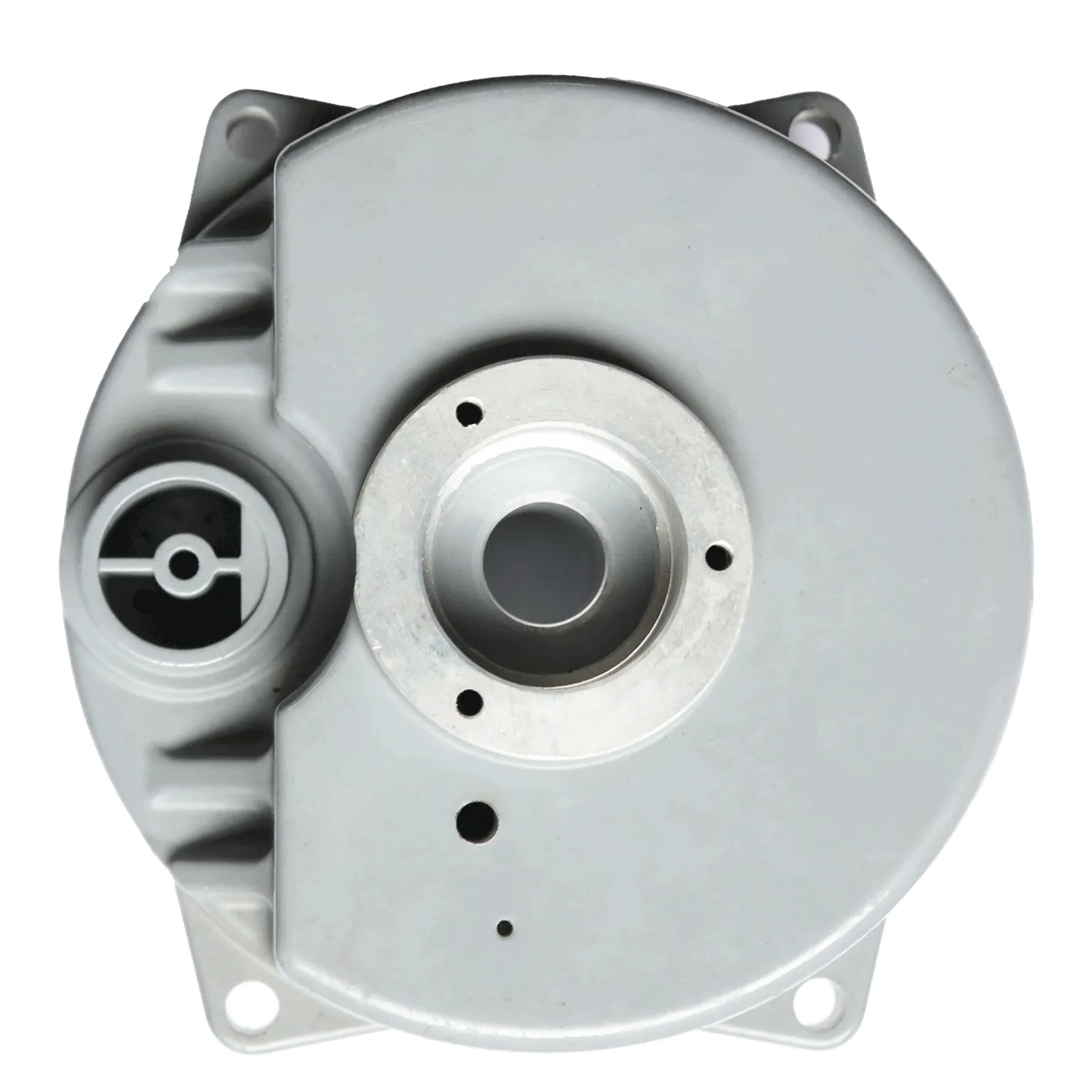

2 inch end cap

Navigating the world of industrial fittings, especially when it comes to components like the 2 inch end cap, can often seem daunting due to the myriad of specifications and applications. However, understanding these critical components is essential, especially for those who deal with pipe systems or are involved in HVAC (Heating, Ventilation, and Air Conditioning) tasks. Through years of hands-on experience and industry insights, the importance of selecting the right 2 inch end cap for both small-scale and extensive systems cannot be overstated.

The expert recommendation is to always verify compatibility with the entire pipe system. An overlooked yet crucial aspect is ensuring that the outer diameter of the pipe and the inner diameter of the cap are a precise match. Any mismatch not only leads to potential leaks but also compromises the system’s structural integrity. Experienced professionals stress the importance of investing in quality manufacturing brands that adhere to international standards, offering reliability and safety assurances. An authoritative voice within the industry also champions the ease of installation as a key factor. Products that offer a seamless integration process save time and labor costs. Innovations in design have led to some end caps featuring intuitive lock systems, which significantly simplify the installation and removal processes without requiring specialized tools. From a trustworthiness perspective, safety protocols and certifications cannot be overlooked. End caps certified by global standards—for instance, ISO or ANSI—add a layer of trustworthiness to their use. Such certifications demonstrate that the products have undergone rigorous testing and surpass quality benchmarks, a factor that professionals in commercial or industrial settings should prioritize. In conclusion, the choice of a 2 inch end cap, while influenced by the specific needs of the application, requires a balance of experience, expert recommendations, authoritative insights, and trust. Ensuring that these components are sourced from reputable manufacturers and are compliant with relevant certifications not only protects your investment but also maintains the seamless operation of your entire system. Always consider the environmental conditions, material compatibility, and installation requirements when making your decision, as these factors collectively contribute to the overall safety and efficiency of your pipework systems.

The expert recommendation is to always verify compatibility with the entire pipe system. An overlooked yet crucial aspect is ensuring that the outer diameter of the pipe and the inner diameter of the cap are a precise match. Any mismatch not only leads to potential leaks but also compromises the system’s structural integrity. Experienced professionals stress the importance of investing in quality manufacturing brands that adhere to international standards, offering reliability and safety assurances. An authoritative voice within the industry also champions the ease of installation as a key factor. Products that offer a seamless integration process save time and labor costs. Innovations in design have led to some end caps featuring intuitive lock systems, which significantly simplify the installation and removal processes without requiring specialized tools. From a trustworthiness perspective, safety protocols and certifications cannot be overlooked. End caps certified by global standards—for instance, ISO or ANSI—add a layer of trustworthiness to their use. Such certifications demonstrate that the products have undergone rigorous testing and surpass quality benchmarks, a factor that professionals in commercial or industrial settings should prioritize. In conclusion, the choice of a 2 inch end cap, while influenced by the specific needs of the application, requires a balance of experience, expert recommendations, authoritative insights, and trust. Ensuring that these components are sourced from reputable manufacturers and are compliant with relevant certifications not only protects your investment but also maintains the seamless operation of your entire system. Always consider the environmental conditions, material compatibility, and installation requirements when making your decision, as these factors collectively contribute to the overall safety and efficiency of your pipework systems.

Next:

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS