Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Feb . 19, 2025 01:38

Back to list

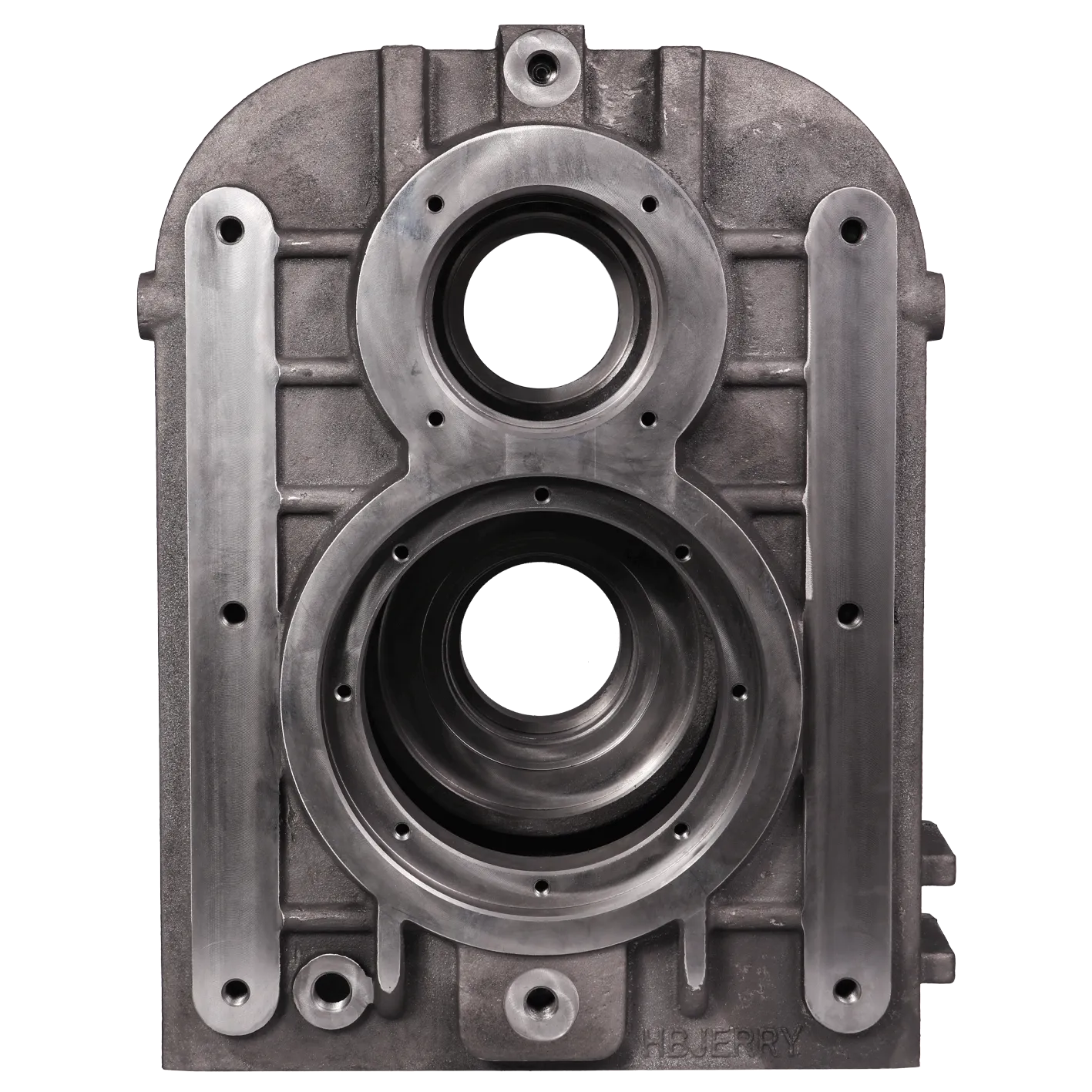

12 impeller

In the intricate world of fluid dynamics, the 12 impeller serves as a cornerstone element in various industrial applications. Its design and functionality are pivotal to the efficiency of pumps, compressors, and other machinery integral to processes in water treatment, chemical manufacturing, and HVAC systems. The distinctive features and benefits of a 12 impeller system demonstrate its importance in optimizing performance across these sectors.

Trustworthiness and authority are introduced through rigorous testing and certification processes that any 12 impeller must undergo before reaching the market. Industry standards such as ISO and ANSI set the benchmark for performance and safety, ensuring that every impeller meets stringent criteria. Manufacturers with longstanding reputations in the sector typically offer extended warranties and comprehensive technical support, which speaks to their commitment to quality and customer satisfaction. From a material perspective, the choice of construction material for a 12 impeller can significantly impact its longevity and effectiveness. Common materials include stainless steel, titanium, and advanced polymers, each offering distinct advantages in terms of strength, corrosion resistance, and weight. For example, in highly corrosive environments, a titanium impeller might be favored for its superior resistance to chemical attack, though at a higher cost. Conversely, advanced polymers may be selected for applications where weight reduction is critical, without compromising on performance. Professionals operating with 12 impeller systems often emphasize the importance of regular maintenance and performance monitoring. Proper installation and routine checks help in identifying potential issues before they result in system failures. Vibration analysis, performance logging, and thermal imaging are some of the techniques used to maintain an impeller’s operational integrity. This predictive maintenance approach not only prolongs the lifespan of the impeller but also minimizes downtime, offering uninterrupted productivity for industries reliant on continuous operation. The broad applicability across diverse industries underscores the 12 impeller’s versatility and engineering sophistication. For clients seeking to optimize their fluid handling capabilities, investing in a high-quality 12 impeller system is a step towards enhanced efficiency, reliability, and sustainability. By leveraging the expertise of seasoned engineers and the authority of certified manufacturers, organizations can trust in the robust performance and adaptability of 12 impellers, achieving operational excellence in their respective fields.

Trustworthiness and authority are introduced through rigorous testing and certification processes that any 12 impeller must undergo before reaching the market. Industry standards such as ISO and ANSI set the benchmark for performance and safety, ensuring that every impeller meets stringent criteria. Manufacturers with longstanding reputations in the sector typically offer extended warranties and comprehensive technical support, which speaks to their commitment to quality and customer satisfaction. From a material perspective, the choice of construction material for a 12 impeller can significantly impact its longevity and effectiveness. Common materials include stainless steel, titanium, and advanced polymers, each offering distinct advantages in terms of strength, corrosion resistance, and weight. For example, in highly corrosive environments, a titanium impeller might be favored for its superior resistance to chemical attack, though at a higher cost. Conversely, advanced polymers may be selected for applications where weight reduction is critical, without compromising on performance. Professionals operating with 12 impeller systems often emphasize the importance of regular maintenance and performance monitoring. Proper installation and routine checks help in identifying potential issues before they result in system failures. Vibration analysis, performance logging, and thermal imaging are some of the techniques used to maintain an impeller’s operational integrity. This predictive maintenance approach not only prolongs the lifespan of the impeller but also minimizes downtime, offering uninterrupted productivity for industries reliant on continuous operation. The broad applicability across diverse industries underscores the 12 impeller’s versatility and engineering sophistication. For clients seeking to optimize their fluid handling capabilities, investing in a high-quality 12 impeller system is a step towards enhanced efficiency, reliability, and sustainability. By leveraging the expertise of seasoned engineers and the authority of certified manufacturers, organizations can trust in the robust performance and adaptability of 12 impellers, achieving operational excellence in their respective fields.

Latest news

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Related PRODUCTS