Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

100mm blanking cap

Understanding the Importance of the 100mm Blanking Cap

In various industrial applications, maintaining efficiency and ensuring the integrity of systems is paramount. One often overlooked yet crucial component in this regard is the 100mm blanking cap. This seemingly simple device plays a significant role in ensuring the effective management of fluid systems and processes.

A blanking cap, also known as a blind cap, is designed to seal the end of a pipe, tube, or fitting, effectively closing off the system. The 100mm diameter specification makes it suitable for a range of applications from plumbing and HVAC to manufacturing and automotive industries. Understanding its utility and functionality can shed light on its role in various operations.

One of the primary functions of a blanking cap is to prevent the ingress of dirt, debris, and contaminants into open pipe systems. This is particularly essential for systems that are not in constant use. For example, in a plumbing system, a 100mm blanking cap can be used to temporarily seal a section of the piping while repairs or maintenance are carried out. This helps to maintain pressure and ensure that the rest of the system remains operational while minimizing the risk of contamination.

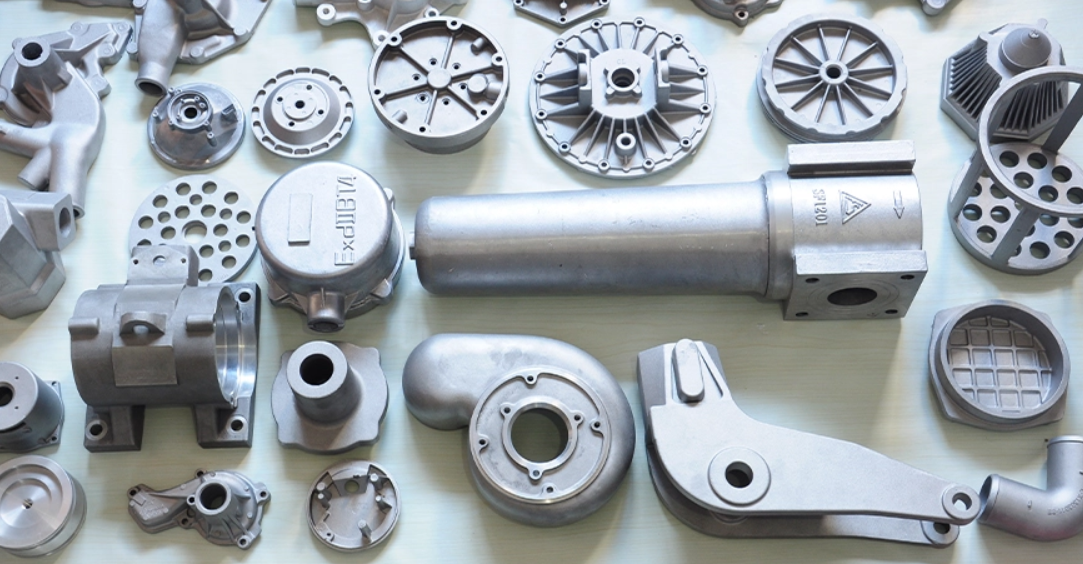

100mm blanking cap

Moreover, the use of a blanking cap can significantly enhance safety in various environments. In industrial settings, pressurized systems must be managed carefully to avoid accidents and leaks. A properly fitted 100mm blanking cap can provide an extra layer of safety, ensuring that hazardous materials do not escape and that workers are protected. Additionally, during transportation of equipment or materials, blanking caps can serve to keep connections pristine and safeguarded from accidental damage.

Blanking caps also play a critical role in system modifications. In instances where a section of a system is no longer in use, installers can simply cap off the end with a 100mm blanking cap instead of making extensive modifications. This saves both time and resources, allowing for a more efficient adaptation to changing operational needs.

While the practicality of a 100mm blanking cap is evident, the materials used in its construction are equally important. Depending on the application, blanking caps can be made from a variety of materials, including plastic, metal, or rubber. Each material offers unique benefits; for instance, a plastic cap might be suitable for lighter applications, while a metal cap may be necessary for high-pressure systems. Understanding the specific requirements of the system in question is essential to select the appropriate blanking cap.

In summary, the 100mm blanking cap may seem like a minor component in the grand scheme of industrial operations, but its importance cannot be overstated. From safeguarding against contamination and enhancing safety to facilitating ease of maintenance and adaptability in systems, blanking caps serve a vital function in a wide array of settings. As industries continue to seek ways to improve efficiency and ensure safety, understanding and properly utilizing components like the 100mm blanking cap will remain crucial in achieving operational excellence.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025