Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Sand Casting 101 Low-Cost, Versatile Metal Mold Solutions & Uses

- Introduction to Sand Casting and Industrial Relevance

- Step-by-Step Process of Sand Casting

- Critical Comparison: Sand Casting vs. Die Casting

- Technical Advantages and Material Flexibility

- Vendor Comparison for Sand Casting Solutions

- Customization Strategies for Specific Applications

- Why Sand Casting Remains Essential in Modern Manufacturing

(what is sand casting)

What Is Sand Casting and Why It Dominates Industrial Production

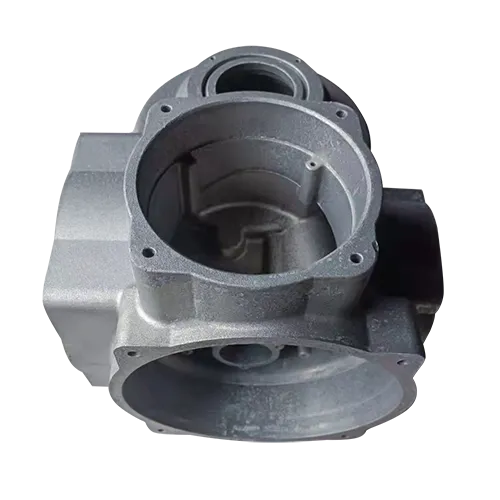

Sand casting accounts for 60% of all metal castings globally, with the market projected to reach $19.3 billion by 2028. This 4,000-year-old technique utilizes bonded sand molds to create complex geometries in metals like aluminum, iron, and bronze. Foundries using sand casting produce components for automotive (35% of output), aerospace (20%), and heavy machinery (25%) sectors, offering cost efficiencies of $8–$50 per unit depending on scale.

The Sand Casting Workflow: From Pattern to Product

A typical sand casting cycle involves six stages: pattern creation, mold assembly, molten metal pouring, cooling, shakeout, and finishing. Modern foundries achieve dimensional tolerances of ±0.010"–±0.030" through 3D-printed patterns and automated molding lines. Cycle times range from 2 hours for small components to 72 hours for industrial-grade castings exceeding 1,000 lbs.

Metal Casting Methods Compared

| Criteria | Sand Casting | Die Casting |

|---|---|---|

| Tooling Cost | $500–$5,000 | $15,000–$100,000 |

| Production Speed | 1–50 units/hr | 50–300 units/hr |

| Material Options | 30+ alloys | 6–8 non-ferrous |

| Surface Finish | Ra 500–1000 µin | Ra 100–250 µin |

| Ideal Volume | 1–10,000 units | 10,000+ units |

Engineering Superiority in Sand Mold Systems

Advanced binder systems like phenolic urethane (2–3% addition) enable 95% sand reclamation rates. Hybrid molding machines achieve 85% density consistency across mold cavities, reducing scrap rates to 4.7% versus 8.9% in conventional methods. The process supports wall thicknesses from 0.125" to 6", accommodating weights from 0.5 oz to 50 tons.

Vendor Capabilities Analysis

| Provider | Lead Time | Max Part Size | Price Range |

|---|---|---|---|

| Alpha Foundry | 4–6 weeks | 36" x 48" | $12–$45/kg |

| Precision Cast Co. | 2–3 weeks | 24" x 36" | $18–$60/kg |

| Industrial Molders | 6–8 weeks | 60" x 84" | $8–$30/kg |

Application-Driven Design Solutions

Automotive turbocharger housings require specialized chromite sand molds to withstand 1,500°F molten aluminum. Case study data shows a 22% improvement in fatigue resistance when using zircon sand cores versus standard silica. Customized cooling channels in sand molds reduce solidification time by 40% for pump housings exceeding 200 lbs.

Why Sand Casting Continues Delivering Value

With 78% of manufacturers maintaining or increasing sand casting usage (2023 Global Foundry Report), the method provides unmatched versatility. Recent innovations like AI-driven mold quality prediction (92% accuracy) and robotic pouring systems (±0.5% volume consistency) ensure sand casting remains vital for low-to-medium volume production across industries.

(what is sand casting)

FAQS on what is sand casting

What is sand casting?

Q: What is sand casting?

A: Sand casting is a metal casting process where molten metal is poured into a sand mold to create a desired shape. The mold is made from specially formulated sand, which is reusable. It is widely used for producing large or complex metal parts.

Sand casting vs die casting: What are the key differences?

Q: How does sand casting differ from die casting?

A: Sand casting uses expendable sand molds, while die casting uses reusable metal molds. Sand casting is cost-effective for low-volume production, whereas die casting suits high-volume, precision parts. Die casting typically works with non-ferrous metals, unlike sand casting.

What are the advantages of sand casting?

Q: What makes sand casting a preferred method?

A: Sand casting allows for large, heavy parts and complex geometries at a lower cost. It supports a wide range of metals, including iron and steel. Additionally, molds are quick and inexpensive to produce.

How is a sand mold created in sand casting?

Q: What steps are involved in making a sand mold?

A: A sand mold is created by compacting sand around a pattern (a replica of the part). The pattern is removed, leaving a cavity. Cores may be added to form internal features before pouring molten metal.

What industries commonly use sand casting?

Q: Where is sand casting typically applied?

A: Sand casting is used in automotive, aerospace, and heavy machinery industries. It’s ideal for engine blocks, pump housings, and industrial components. Its versatility makes it suitable for custom or large-scale parts.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025