Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Techniques of Wax Mold Casting in Metalworking

Wax Mold Casting An Overview of the Process and Its Applications

Wax mold casting, often referred to as investment casting, is a sophisticated and versatile manufacturing process widely used in various industries, including aerospace, automotive, and art. The method involves creating intricate and precise metal parts from a wax pattern, which is subsequently melted away to leave a cavity for molten metal. This article delves into the various stages of wax mold casting, its advantages, and its applications in contemporary manufacturing.

The Process of Wax Mold Casting

The wax mold casting process begins with the creation of a wax pattern. This pattern is a precise replica of the final product and can be crafted from various types of wax, depending on the desired finish and detail level. Once the pattern is created, it is coated with a ceramic shell made from a mixture of fine sand and a heat-resistant binder. This coating process involves several steps of applying and drying to build a sturdy mold around the wax pattern.

After the ceramic shell has sufficiently hardened, the mold is heated in an oven to melt and drain the wax, leaving a hollow shell. This step is crucial as it establishes the exact shape needed for the metal casting. Once the wax is removed, the mold is heated again to ensure it is at the correct temperature for pouring in the molten metal.

Next, molten metal, typically steel, aluminum, or bronze, is poured into the mold. The high precision of the wax mold allows for detailed patterns and fine features in the final cast piece. After the metal has cooled and solidified, the ceramic shell is broken away to reveal the cast component. The final steps often include sanding and polishing to enhance the surface finish and remove any imperfections.

Advantages of Wax Mold Casting

Wax mold casting boasts several advantages that make it an attractive option for manufacturers. One of the primary benefits is its ability to produce highly complex shapes with intricate details. The precision of the process reduces the need for machining and other finishing operations, which can save time and costs.

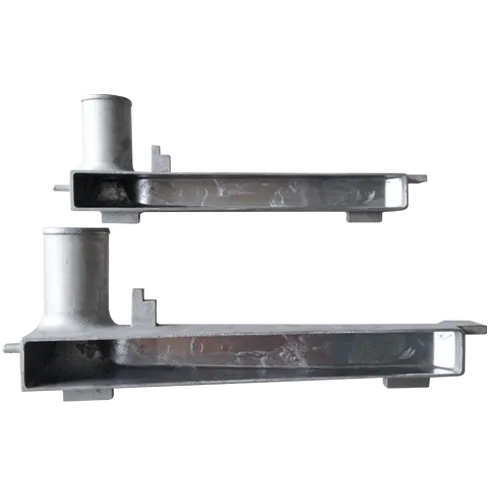

wax mold casting

Moreover, the versatility of materials used in combinations with wax mold casting is notable

. Various types of metals can be poured into the molds with little alteration to the process, making it adaptable for diverse applications. The process also allows for repeatability, enabling manufacturers to produce multiple identical parts with minimal variance.Another significant advantage is the excellent surface finish achieved through wax mold casting. The smooth finish of the wax patterns translates into a high-quality surface on the final product, often eliminating the need for additional finishing steps.

Applications of Wax Mold Casting

The applications of wax mold casting are vast and varied. In the aerospace and automotive industries, it is used to create complex components such as turbine blades, engine parts, and other intricate assemblies that require high precision and performance. The characteristics of the material cast using this method, such as strength and durability, make it suitable for high-stress applications.

Beyond industrial applications, wax mold casting is also prevalent in jewelry making and art. Jewelers utilize this method to produce intricate designs and custom pieces, allowing for creative freedom in the design process. Artists also take advantage of wax mold casting to create sculptures and detailed art pieces.

In the medical field, it plays a role in creating highly specialized components such as implants and surgical instruments. The ability to produce custom shapes and sizes is crucial in providing effective and personalized medical solutions.

Conclusion

Wax mold casting is a remarkable technique that exemplifies the intersection of craftsmanship and technology. With its precision, flexibility, and ability to produce complex geometries, it has secured its place in various industries. As technology advances, the wax mold casting process is expected to evolve further, enhancing its efficiency and broadening its scope of applications. Whether in manufacturing, art, or medicine, the implications of this technique are profound, showcasing the continual innovation that drives modern industry.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025