Mobile:+86-311-808-126-83

Email:info@ydcastings.com

water pump motor impeller

Understanding the Role of Water Pump Motor Impellers

Water pumps are essential devices used in countless applications, from irrigation systems and municipal water supply to industrial processes and residential plumbing. At the heart of most water pumps lies the impeller, a critical component that directly influences the efficiency and performance of the pump, particularly when paired with an electric motor. This article will delve into the importance of the water pump motor impeller, its function, types, and some considerations relevant to maintenance and selection.

What is an Impeller?

The impeller is a rotating component of a pump designed to move fluids by converting rotational energy provided by the motor into kinetic energy. Essentially, when the motor turns the impeller, it creates a low-pressure area that draws fluid into the pump. As the impeller spins, the shape of its blades pushes the fluid outward, causing it to exit through the pump outlet. This centrifugal action is fundamental to the operation of centrifugal pumps, the most common type of pump used in various applications.

The Function of the Impeller

The impeller plays a pivotal role in determining how effectively a water pump can move liquids. Several factors related to the impeller significantly affect the pump's performance

1. Flow Rate The design and size of the impeller influence the volume of liquid that can be pumped in a given time. A larger or more aerodynamically designed impeller will generally facilitate a higher flow rate.

2. Head Pressure The impeller's design also impacts the head pressure—the height to which a pump can raise water. The more effectively the impeller can harness the motor's energy, the higher the potential head.

3. Efficiency Impellers are designed to minimize energy loss; an efficient impeller can reduce operational costs by ensuring that more of the motor's energy is converted into useful work.

4. Fluid Handling The type of fluid being pumped (clean water, sludge, chemicals, etc.) dictates the choice of impeller design. For example, a pump handling slurry may require a different impeller compared to one moving clean water.

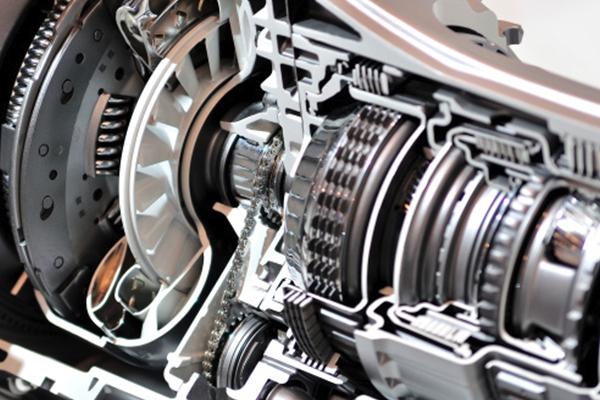

Types of Impellers

water pump motor impeller

There are various designs of impellers that cater to different pumping needs

1. Closed Impellers Featuring two shrouded sides, these impellers are efficient and commonly used in applications requiring high pressure and flow.

2. Open Impellers With no shrouds, open impellers are easier to clean and are used for moving liquids that contain solids.

3. Semi-Open Impellers These have one shroud and are suitable for various applications, providing a balance between efficiency and the ability to handle solids.

4. Vertical and Submersible Impellers Designed for specific applications, these impellers work effectively in wells and submerged situations.

Maintenance and Selection

Choosing the right water pump motor impeller is crucial for optimal performance. Factors such as material composition (cast iron, stainless steel, or thermoplastics), design, size, and compatibility with the motor should be considered. It’s essential to match the impeller with the requirements of the system, including flow rate and head pressure specifications.

Regular maintenance of the impeller is equally vital. Over time, impellers can wear down due to the abrasive nature of the fluid being transported. Inspections should be scheduled to check for wear and tear, and any debris should be cleaned to prevent clogs. Additionally, monitoring the pump's performance can indicate when an impeller may need replacement.

Conclusion

In conclusion, the water pump motor impeller is a fundamental component that significantly influences the efficiency and effectiveness of water pumps. From its design and function to the selection and maintenance of the right type, understanding the intricacies of impellers can lead not only to improved pump performance but also to energy savings and lower operational costs. Whether you're involved in industrial applications, agricultural practices, or municipal water management, appreciating the role of the impeller is key to ensuring systems run smoothly and efficiently.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025