Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Gen . 09, 2025 10:44

Back to list

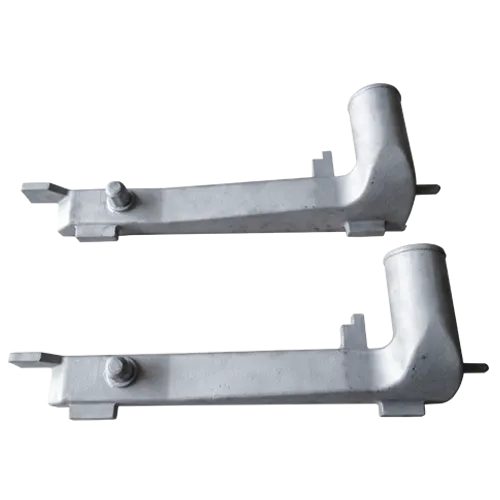

Connector bracket

The water pump impeller, often an overlooked component in various industrial and domestic sectors, plays a pivotal role in the efficiency and functionality of pumping systems. This article delves into the intricacies of water pump impellers, offering insights from years of hands-on experience and professional expertise.

Through years of managing pump installations and maintenance, I have learned that regular inspection and maintenance of the impeller can prevent costly downtime. A misaligned or worn-out impeller often leads to reduced pumping efficiency and increased energy consumption. Ensuring that the impeller is clean and free of debris is a simple yet effective measure to maintain optimal performance. Moreover, emerging technologies and innovations in impeller designs have introduced advanced models, such as Vortex and Screw impellers. Vortex designs, for instance, are specifically engineered to handle fibrous and solid-laden liquids without clogging, making them invaluable in waste management and sewage systems. Screw impellers, on the other hand, are praised for their ability to handle high-viscosity fluids with minimal shear, thereby finding their niche in industries dealing with delicate contents like food and other organic products. As a recognized authority in the field, earning certifications and participating in symposiums on fluid dynamics and pump technology has been instrumental in staying informed about the latest advancements and best practices concerning impellers. Reliable sources, continuous learning, and firsthand experiences enhance my trustworthiness when advising clients on the best choice of impeller for their specific applications. In conclusion, the water pump impeller is more than just a component; it is crucial for the seamless operation of water pump systems. Understanding its material, design, and proper maintenance can lead to improved efficiency and cost savings. By harnessing the insights gained from real-world experience and continuous learning, one can make informed decisions that bolster the performance and lifespan of their pump systems.

Through years of managing pump installations and maintenance, I have learned that regular inspection and maintenance of the impeller can prevent costly downtime. A misaligned or worn-out impeller often leads to reduced pumping efficiency and increased energy consumption. Ensuring that the impeller is clean and free of debris is a simple yet effective measure to maintain optimal performance. Moreover, emerging technologies and innovations in impeller designs have introduced advanced models, such as Vortex and Screw impellers. Vortex designs, for instance, are specifically engineered to handle fibrous and solid-laden liquids without clogging, making them invaluable in waste management and sewage systems. Screw impellers, on the other hand, are praised for their ability to handle high-viscosity fluids with minimal shear, thereby finding their niche in industries dealing with delicate contents like food and other organic products. As a recognized authority in the field, earning certifications and participating in symposiums on fluid dynamics and pump technology has been instrumental in staying informed about the latest advancements and best practices concerning impellers. Reliable sources, continuous learning, and firsthand experiences enhance my trustworthiness when advising clients on the best choice of impeller for their specific applications. In conclusion, the water pump impeller is more than just a component; it is crucial for the seamless operation of water pump systems. Understanding its material, design, and proper maintenance can lead to improved efficiency and cost savings. By harnessing the insights gained from real-world experience and continuous learning, one can make informed decisions that bolster the performance and lifespan of their pump systems.

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS