Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Valve Solutions for Industrial Applications | Innovative Control Technology

The Versatility and Importance of Valves in Modern Engineering

Valves are integral components across various industries and applications, often acting as the unsung heroes of mechanical systems. These devices regulate the flow of fluids, gases, and slurries, ensuring that processes run smoothly and efficiently. While their design and function may seem simple, the role of valves is crucial in everything from water supply systems to advanced aeronautics.

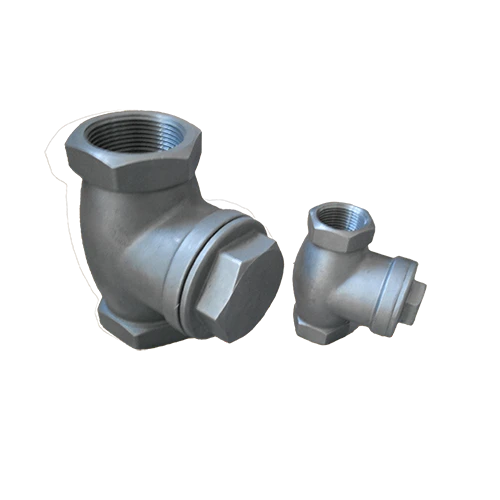

Valves come in a variety of shapes and sizes, each tailored for specific applications. The most common types include gate valves, globe valves, ball valves, and check valves. Gate valves are primarily used for on-off control; they provide a straight-line flow path when fully opened, minimizing pressure loss. Globe valves, on the other hand, are designed for throttling purposes and have a higher resistance to flow, making them ideal for regulating fluid levels. Ball valves offer quick shut-off capabilities and are perfect for tight sealing, while check valves prevent backflow, ensuring that fluids move in one direction only.

The materials used in valve construction are as diverse as their applications. Common materials include metals like stainless steel and brass, as well as durable plastics such as PVC and CPVC. The choice of material not only affects valve performance but also influences corrosion resistance, temperature tolerance, and compatibility with various fluids. In industries where valve failure could lead to catastrophic consequences—such as oil and gas or pharmaceuticals—using the right materials is vital.

In municipal water systems, valves play a crucial role in maintaining the integrity and safety of water supply

. They control flow rates, isolate sections of the system for maintenance, and prevent contamination. Similarly, in the field of HVAC (heating, ventilation, and air conditioning), valves help in regulating temperatures and ensuring efficient distribution of air and fluids.valve

The use of valves extends into industries such as food and beverage, where sanitary valves are critical for maintaining hygiene standards. These valves are designed to be easily cleaned and are often constructed from non-reactive materials to prevent contamination of food products.

As industries continue to evolve, so do the technologies surrounding valves. Innovations such as smart valves incorporate sensors and IoT (Internet of Things) technology, allowing for remote operation and real-time monitoring of conditions such as pressure and temperature. This advancement significantly enhances the efficiency of industrial processes and enables predictive maintenance, thereby minimizing downtime and reducing operational costs.

Moreover, the environmental impact of valve design and operation is becoming increasingly important. Manufacturers are now focusing on developing energy-efficient valves that minimize emissions and conserve resources. This trend aligns with the global push towards sustainability, ensuring that modern engineering practices consider ecological footprints.

In conclusion, valves are more than mere mechanical devices; they are essential components that facilitate the smooth operation of countless systems across various industries. Their versatility, coupled with advancements in technology and materials, ensures that valves will continue to play a pivotal role in the future of engineering and industrial processes. Whether regulating water flow, managing pneumatic systems, or ensuring safety in chemical manufacturing, the significance of valves cannot be overstated. As we move forward, the continued evolution of valve technology will undoubtedly contribute to more efficient, safe, and sustainable operations in our modern world.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025