Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Design and Functionality of Turbocharger Turbine Housings in Performance Engines

The Importance of Turbo Turbine Housing in Modern Engines

Turbo turbine housing plays a crucial role in the performance and efficiency of modern engines, particularly in turbocharged vehicles. As automotive technology continues to evolve, the design and functionality of turbo turbine housing has become increasingly sophisticated, making it a key component in enhancing engine performance.

At its core, the turbo turbine housing is designed to house the turbine wheel, which is directly connected to the exhaust side of a turbocharger. The primary function of this housing is to guide the exhaust gases from the engine to the turbine wheel, allowing it to spin at high speeds. As the turbine wheel rotates, it drives the compressor wheel located on the intake side of the turbocharger, leading to a significant increase in the amount of air drawn into the engine. This boost in air increases the engine's power output and efficiency, a process known as forced induction.

One of the most notable benefits of turbo turbine housing is its ability to improve engine efficiency. By utilizing exhaust gases that would otherwise be wasted, turbochargers can extract additional power from the same amount of fuel. This not only enhances performance but also contributes to better fuel economy, which is a critical consideration in today’s environmentally conscious society. Engine manufacturers are continually working to optimize the design of turbo turbine housings to minimize backpressure and improve the flow of exhaust gases, further enhancing the performance benefits of turbocharging.

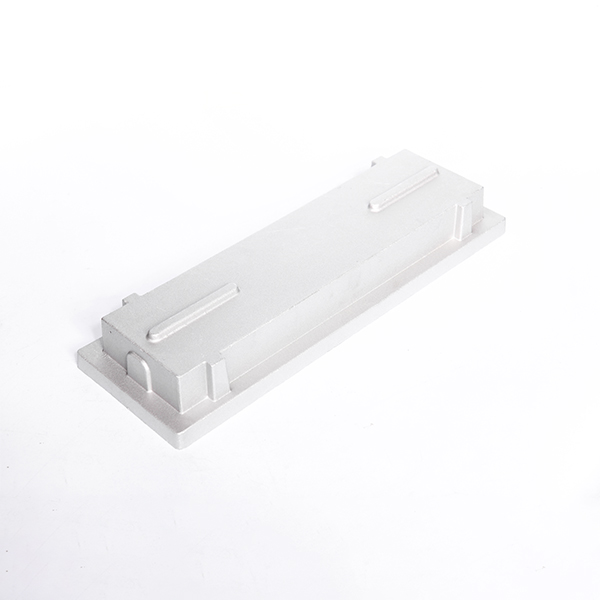

turbo turbine housing

Another significant aspect of turbo turbine housing is its material composition. Most modern turbo turbine housings are made from high-strength alloys that can withstand extreme temperatures and pressures. The materials used must be heat resistant as the exhaust gases can reach incredibly high temperatures. Advanced manufacturing techniques, including precision casting and machining, are also employed to ensure that the housings meet rigorous performance and durability standards.

In addition, the design of the turbo turbine housing is integral to controlling the sound produced by the turbocharger. By optimizing the shape and size of the housing, engineers can manage the noise levels while still maintaining an efficient flow of exhaust gases. This balancing act is essential in meeting the stringent noise regulations imposed on modern vehicles.

In summary, turbo turbine housing is a vital component in turbocharged engines, playing a significant role in enhancing efficiency and performance. Its advanced materials, design, and functionality contribute to the overall effectiveness of turbocharging technology. As the automotive industry continues to push towards higher efficiency and lower emissions, the evolution of turbo turbine housing will undoubtedly remain at the forefront of engineering innovation.

-

What Makes Stainless Steel Pump Casting Essential for Modern Industries?NewsJul.14,2025

-

Revolutionize Your Engine Maintenance with Premium Aluminum and Cast Iron ComponentsNewsJul.14,2025

-

Precision Flow Engineering Starts with the Right Pump ComponentsNewsJul.14,2025

-

Maximize Efficiency: Explore Reliable Containment and Crop SolutionsNewsJul.14,2025

-

Discover Superior Performance with Advanced Turbo ComponentsNewsJul.14,2025

-

Boost Fluid Dynamics with Precision-Engineered Pump ComponentsNewsJul.14,2025