Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Design and Functionality of Turbo Compressor Covers in Modern Engineering

Understanding Turbo Compressor Covers Function, Design, and Applications

In the world of turbocharging, many components work together to improve the performance of internal combustion engines. One critical yet often overlooked element is the turbo compressor cover. While it may seem like a simple component, the turbo compressor cover plays a significant role in the overall efficiency, performance, and durability of a turbocharger system. This article explores the function, design, and applications of turbo compressor covers, highlighting their importance in automotive engineering.

Function of the Turbo Compressor Cover

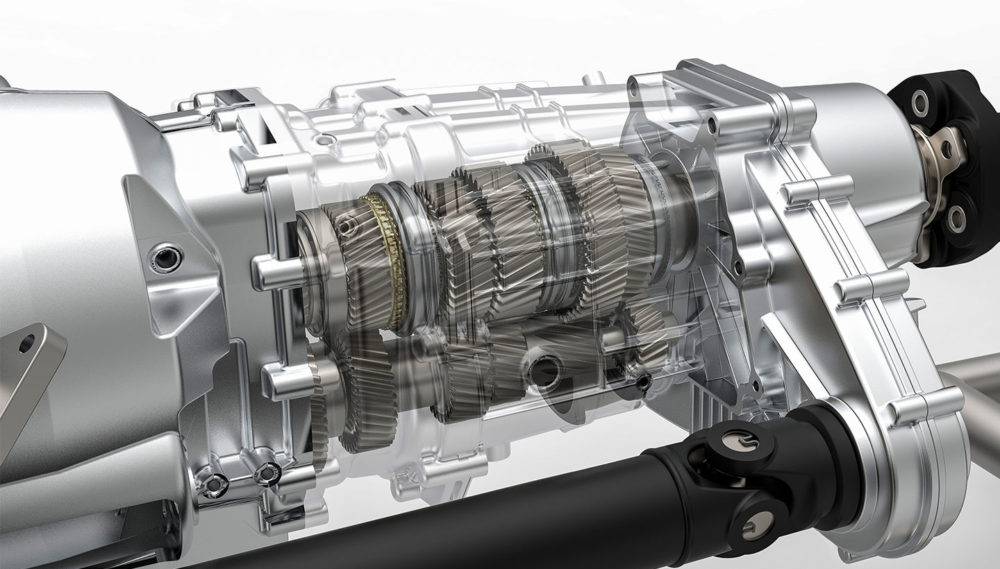

The primary function of a turbo compressor cover is to provide a housing for the compressor wheel. This component is essential for compressing incoming air before it enters the engine's combustion chamber. By increasing the pressure and density of the air, the turbo compressor enables the engine to burn more fuel, resulting in greater power output and improved efficiency.

Moreover, the compressor cover helps direct airflow efficiently through the compressor, minimizing turbulence and maximizing performance. It also houses the wastegate mechanism, which controls the amount of boost produced by the turbocharger. By regulating the boost pressure, the wastegate ensures that the engine operates within safe limits, preventing potential damage due to over-boosting.

Design Considerations

Turbo compressor covers are typically designed from materials that can withstand high temperatures and pressures while maintaining structural integrity. Common materials include aluminum, which offers a lightweight yet strong solution, and various high-temperature alloys that can endure the extreme conditions found within turbocharged engines.

The design of the compressor cover also varies based on the specific application and the desired performance characteristics. Factors such as the size and shape of the inlet and outlet ports, the geometry of the internal passages, and the overall configuration of the cover can significantly affect airflow dynamics and compressor efficiency.

For high-performance applications, manufacturers often use advanced simulation techniques to optimize the compressor cover design. Computational fluid dynamics (CFD) simulations allow engineers to visualize airflow patterns, identify choke points, and make necessary adjustments before the physical prototype is created.

turbo compressor cover

Applications in the Automotive Industry

Turbo compressor covers are predominantly found in the automotive industry, particularly in turbocharged engines used in cars, trucks, and motorcycles. They are popular in both production vehicles and aftermarket modifications, where enthusiasts seek to increase their engine's performance.

In racing applications, custom turbo compressor covers are frequently designed to cater to specific racing conditions. These covers may incorporate larger inlet and outlet diameters, improved internal geometries, and lightweight materials to enhance overall performance.

In addition to automotive applications, turbo compressor covers are also used in aviation and industrial engines. Aircraft engines, for instance, utilize turbocharging to improve efficiency and power output at higher altitudes. Similarly, in industrial settings, turbochargers help boost the efficiency of large diesel engines used in machinery and generators.

Maintenance and Upgrades

Like other components of a turbocharger, turbo compressor covers require regular inspection and maintenance to ensure optimal performance. Elements such as excessive heat, debris buildup, or signs of wear can negatively impact the compressor cover's function. Routine checks can help identify potential issues before they escalate into more significant problems.

For those looking to enhance engine performance, upgrading the turbo compressor cover can be a straightforward yet effective approach. High-performance aftermarket covers can provide improved airflow and efficiency, contributing to an overall increase in power. These upgrades are particularly popular among car enthusiasts looking to extract more performance from their turbocharged engines.

Conclusion

The turbo compressor cover serves as a vital component in turbocharger systems, facilitating efficient airflow and enhancing engine performance. Its design and functionality are integral to the overall efficiency and reliability of turbocharged engines in various applications. As technology advances and automotive engineering continues to evolve, the importance of the turbo compressor cover will only become more pronounced, driving innovations that lead to even greater performance and efficiency in the world of turbocharging. Whether in street cars, race vehicles, or industrial engines, understanding and optimizing the turbo compressor cover can lead to significant gains in power and efficiency.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025