Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Uses of Tubing Caps in Various Applications

Understanding Tubing Caps Essential Components for Various Applications

Tubing caps are essential components used in a variety of industries, including medical, industrial, and consumer products. They serve to protect the ends of tubes and prevent contamination, ensuring the integrity of the contents they enclose. In this article, we will explore the different types of tubing caps, their applications, and the materials commonly used in their manufacturing.

Types of Tubing Caps

Tubing caps come in various forms, designed to suit specific applications. The most common types include

1. Standard Caps These are the most generic form of tubing caps. Usually made from plastic or rubber, they fit over the open end of a tube to seal it securely.

2. Leak-proof Caps In industries such as pharmaceuticals and food production, leak-proof caps are crucial. They are designed to prevent any leakage of liquids, thus safeguarding the contents and maintaining hygiene.

3. Child-resistant Caps Commonly found in medicinal packaging, these caps require a particular technique to open, making them difficult for children to access.

4. Tamper-evident Caps Often used for packaging food and pharmaceuticals, these caps indicate whether a product has been opened or tampered with, enhancing consumer safety.

5. Custom Caps Many companies opt for custom-designed caps that fit their specific tubing dimensions and requirements. These can include specialized sealing features or branding elements.

Applications of Tubing Caps

tubing caps

The applications of tubing caps are vast and varied. In the medical field, tubing caps are utilized in the packaging of sterile instruments, preventing exposure to contaminants. In laboratories, they are used on test tubes to ensure samples remain uncontaminated. In the industrial sector, tubing caps protect hydraulic and pneumatic hoses from dust and debris during storage and transport.

Moreover, in the consumer products industry, tubing caps are frequently used in the packaging of products like lotions, creams, and various household items, ensuring ease of use while maintaining the quality of the product inside.

Materials Used in Tubing Caps

Tubing caps can be made from numerous materials, depending on their intended use. The most common materials include

- Plastic Lightweight and cost-effective, plastic is widely used for standard caps. Types such as polyethylene and polypropylene are often favored for their durability and resistance to chemicals.

- Rubber Used for caps that require flexibility and a tight seal, rubber caps are especially useful in applications needing sterility.

- Metal In certain industrial applications, metal caps provide additional strength and resistance to extreme conditions.

Conclusion

In conclusion, tubing caps play a crucial role in various industries, protecting the integrity of enclosed materials and preventing contamination. With diverse types and materials available, these components are tailored to meet the specific needs of different applications, ensuring safety, reliability, and efficiency. As industries continue to evolve, the demand for innovative and effective tubing caps will remain significant, contributing to the quality and safety of products worldwide.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

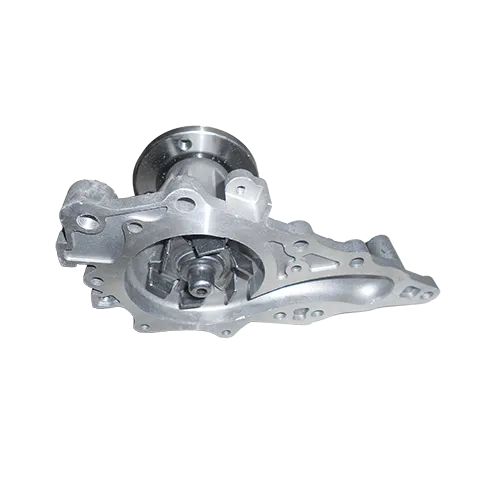

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025