Mobile:+86-311-808-126-83

Email:info@ydcastings.com

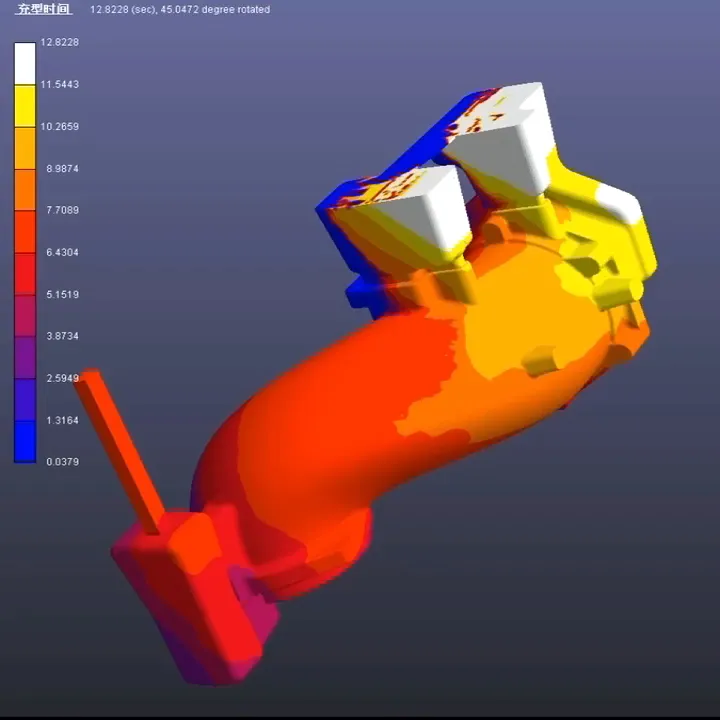

trash pump impeller

Understanding Trash Pump Impellers Function, Design, and Applications

Trash pumps are specialized pumps designed to handle dirty, debris-laden water that regular pumps cannot effectively manage. A critical component of a trash pump is its impeller, which plays a vital role in determining the pump's efficiency and capability to handle heavy solids. This article delves into the function, design, and applications of trash pump impellers, offering insights into their significance in various industries.

Function of Trash Pump Impellers

The primary function of a trash pump impeller is to create fluid movement by converting rotational energy from the motor into kinetic energy in the liquid being pumped. When the motor spins the impeller, its blades move the water through the pump casing and out into the discharge line. What sets trash pump impellers apart from standard pump impellers is their ability to manage solid particles and debris without clogging.

Trash pump impellers are typically designed with larger passages and wider openings to accommodate solid waste, such as sticks, leaves, and mud. This capacity allows the trash pump to transport dirty water in construction sites, flooded areas, and wastewater treatment facilities. The impeller's shape affects both flow rate and pressure, making it essential for designers to select the appropriate impeller type based on the specific application requirements.

Design Elements of Trash Pump Impellers

Trash pump impellers come in several designs, including open, semi-open, and closed configurations. Each design has its advantages and disadvantages, which can impact the pump's performance.

1. Open Impellers These consist of blades that are not enclosed by a shroud. Open impellers are highly effective for pumping liquids with high solids content due to their excellent ability to handle debris. They tend to have a lift capacity but can generate more turbulence, possibly restricting flow efficiency.

2. Semi-Open Impellers This design features a partial covering of the impeller blades. Semi-open impellers offer better protection against clogging compared to open impellers while still providing reasonable performance for debris-rich fluids. They strike a balance between efficiency and solid handling.

3. Closed Impellers These impellers have blades enclosed by a shroud on both sides. They are primarily used for pumping clean liquids and are less effective in trash pump applications due to their vulnerability to clogging. However, in situations where the solid content is low, closed impellers can provide a higher head and greater efficiency.

Materials Used in Impeller Construction

The materials used in constructing trash pump impellers significantly affect their durability and corrosion resistance. Depending on the application, impellers may be made from

trash pump impeller

- Cast Iron Commonly used due to its strength and durability, cast iron can withstand harsh environments but may be susceptible to rust over time.

- Stainless Steel More resistant to corrosion, stainless steel impellers are suitable for applications involving chemical exposure or environments with saltwater.

- Plastic and Composite Materials Lightweight and resistant to corrosion, these materials are increasingly popular for their ability to handle abrasive solids without significant wear.

Applications of Trash Pump Impellers

Trash pump impellers are utilized in a wide range of applications, including

- Construction Sites For dewatering foundations and excavations where muddy or debris-filled water is prevalent.

- Flood Recovery Essential for pumping out floodwaters that contain sediments, leaves, and other debris.

- Agricultural Uses Such as irrigating fields or draining ponds that gather runoff and detritus.

- Wastewater Treatment In processing plants, where solids must be managed without causing downtime related to clogs.

Conclusion

In summary, trash pump impellers are vital components that ensure effective fluid movement in challenging conditions. Their unique designs and material compositions enable trash pumps to handle solid-laden fluids efficiently. Understanding the various types of impellers and their applications is crucial for selecting the right equipment for specific needs. As industries continue to evolve and face new challenges, the importance of reliable trash pumps, and their impellers will remain a cornerstone of efficient fluid management practices. Whether in construction, flood recovery, agriculture, or wastewater treatment, effective trash pump impellers are fundamental to operational success.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025