Mobile:+86-311-808-126-83

Email:info@ydcastings.com

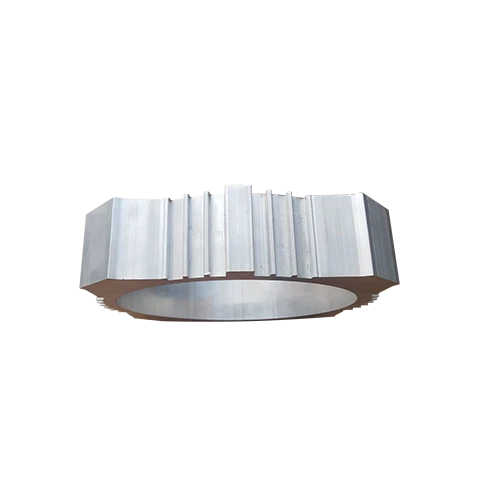

Durable Stainless Steel Housing for Enhanced Turbine Performance and Longevity

The Advantages of Stainless Steel Turbine Housings

In the world of engineering and industrial manufacturing, materials play a crucial role in the performance, durability, and overall efficiency of components. One such critical component is the turbine housing, which is pivotal in various applications including power generation, aerospace, and automotive industries. Among the various materials used for turbine housings, stainless steel has emerged as a premier choice, thanks to its exceptional properties and benefits.

Corrosion Resistance

One of the most significant advantages of stainless steel is its corrosion resistance. Turbines are often exposed to harsh environments, including high humidity, variations in temperature, and exposure to chemically aggressive substances. Stainless steel, particularly grades like 304 and 316, contains chromium which forms a protective oxide layer on the surface. This layer prevents rust and other forms of corrosion, ensuring the turbine housing maintains its integrity over time. This inherent resistance to corrosion not only prolongs the lifespan of the housing but also reduces maintenance costs, which is a crucial factor for many industries.

Strength and Durability

Stainless steel is known for its exceptional strength-to-weight ratio, making it an ideal material for turbine housings that must withstand high operating pressures and temperatures. The mechanical properties of stainless steel allow turbine housings to perform effectively in demanding conditions without succumbing to wear or deformation. Its durability ensures that the housing can endure the mechanical stresses of turbine operation, thereby maintaining efficiency and performance over long periods.

Thermal Stability

stainless steel turbine housing

In the context of turbine applications, thermal stability is another critical factor. Stainless steel exhibits good thermal conductivity, which helps in dissipating heat generated during turbine operations. This property is particularly important in environments where temperature fluctuations are significant. By maintaining consistent thermal performance, stainless steel turbine housings help prevent thermal fatigue and stress, enhancing the overall reliability of the turbine system.

Fabrication and Versatility

Stainless steel is versatile and can be easily fabricated into complex shapes and designs required for turbine housings. Modern manufacturing techniques, such as CNC machining and 3D printing, allow for precise machining of stainless steel, leading to better fitting components and reduced assembly time. The ability to produce lightweight yet strong structures makes stainless steel a favored choice in applications where both performance and efficiency are paramount.

Environmental Impact

As the global focus shifts toward sustainability, the environmental impact of materials becomes increasingly important. Stainless steel is 100% recyclable, making it an eco-friendly option. In addition to being recyclable, the extended lifespan of stainless steel turbine housings contributes to reduced material waste and resource consumption over time, aligning with global sustainability goals.

Conclusion

In conclusion, the use of stainless steel for turbine housings offers numerous advantages, including superior corrosion resistance, strength, thermal stability, versatility in fabrication, and positive environmental impact. As industries continue to evolve and adopt more efficient solutions, stainless steel turbine housings will likely remain at the forefront of engineering innovations. By choosing stainless steel, manufacturers can ensure their turbine systems operate reliably and efficiently while minimizing maintenance and maximizing sustainability. The future of turbine technology appears bright, with stainless steel poised to play a central role in advancing performance and durability in various applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025