Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Applications and Benefits of Stainless Steel Foundries in Modern Industries

The Role of Stainless Steel Foundries in Modern Manufacturing

Stainless steel foundries play a critical role in the manufacturing sector, providing essential materials for a variety of applications. The process of creating stainless steel involves the melting and casting of metal alloys that offer superior resistance to corrosion, heat, and oxidation. This unique combination of properties makes stainless steel a preferred material across industries, including automotive, aerospace, construction, and medical.

The Role of Stainless Steel Foundries in Modern Manufacturing

Once the stainless steel is melted, it is poured into molds to create specific shapes and components. The casting process can involve various methods, including sand casting, investment casting, and continuous casting. Each method has its advantages and is selected based on the complexity of the part and the required finish. Sand casting, for instance, is often used for large components, while investment casting is favored for intricate designs that demand high precision.

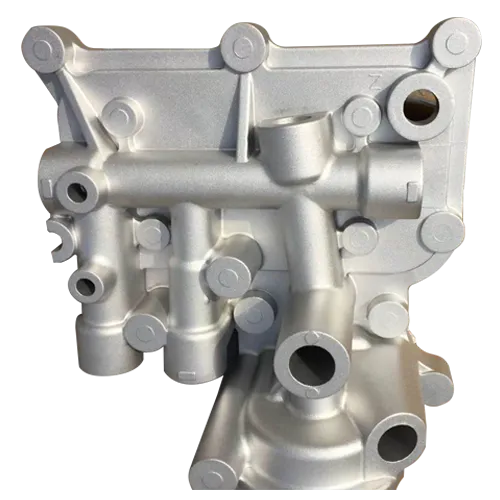

stainless steel foundry

Quality control is paramount in stainless steel foundries. The end products must meet strict industry standards to ensure durability and reliability. Foundries often employ stringent testing methods, such as spectroscopy for chemical composition analysis and non-destructive testing (NDT) to detect any imperfections in the final products. This commitment to quality not only benefits manufacturers but also enhances the overall safety and performance of the final applications.

Moreover, stainless steel foundries are increasingly integrating sustainable practices into their operations. Recycling scrap metal is common in the industry, with a significant percentage of stainless steel being derived from recycled materials. This not only reduces waste but also conserves natural resources and reduces the carbon footprint associated with primary metal production.

In conclusion, stainless steel foundries are vital contributors to modern manufacturing, supplying high-quality materials that are essential for a wide array of industries. Their ability to combine advanced technology, rigorous quality control, and sustainable practices positions them at the forefront of both innovation and environmental responsibility. As the demand for stainless steel continues to grow, these foundries will undoubtedly play an even more significant role in shaping the future of manufacturing.