Mobile:+86-311-808-126-83

Email:info@ydcastings.com

stainless investment casting

Stainless Steel Investment Casting A Comprehensive Overview

Stainless steel investment casting is a precise and efficient manufacturing process that has gained widespread popularity across various industries. This technique allows for the production of complex and intricate metal parts with exceptional surface finishes and dimensional accuracy. In this article, we will explore the benefits, applications, and technological advancements in stainless steel investment casting.

What is Stainless Steel Investment Casting?

Investment casting, often referred to as lost-wax casting, involves creating a metal part by using a wax pattern that is coated in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity in the shape of the desired object. Molten stainless steel is then poured into this cavity, solidifying to form a precise duplicate of the original wax pattern. The use of stainless steel in this process is particularly advantageous due to its excellent corrosion resistance, mechanical properties, and aesthetic qualities.

Benefits of Stainless Steel Investment Casting

1. Precision and Detail One of the primary advantages of investment casting is its ability to produce highly detailed parts with fine tolerances. Stainless steel investment casting can achieve tight tolerances of ±0.005 inches, enabling manufacturers to create intricate designs that would be challenging or impossible with other methods.

2. Material Efficiency Investment casting minimizes waste material, as the process can achieve nearly 100% yield. This efficiency not only conserves resources but also leads to cost savings, making it a preferred choice for large-scale production.

3. Versatility of Design Stainless steel investment casting accommodates a wide range of designs, from simple geometries to highly complex shapes. This versatility makes it suitable for various applications, including automotive, aerospace, medical, and industrial components.

4. Superior Surface Finish The casting process yields excellent surface finishes, often eliminating the need for extensive post-processing. The smooth surface of cast parts is especially important in industries where aesthetics and cleanliness are paramount.

5. Corrosion Resistance Stainless steel is well-known for its corrosion-resistant properties, making it ideal for components exposed to harsh environments. This characteristic ensures longevity and reliability in critical applications.

Applications of Stainless Steel Investment Casting

stainless investment casting

Stainless steel investment casting finds applications in numerous industries due to its unique properties. Some common applications include

- Aerospace Components Parts such as turbine blades, engine mounts, and housings benefit from the high strength and lightweight nature of stainless steel.

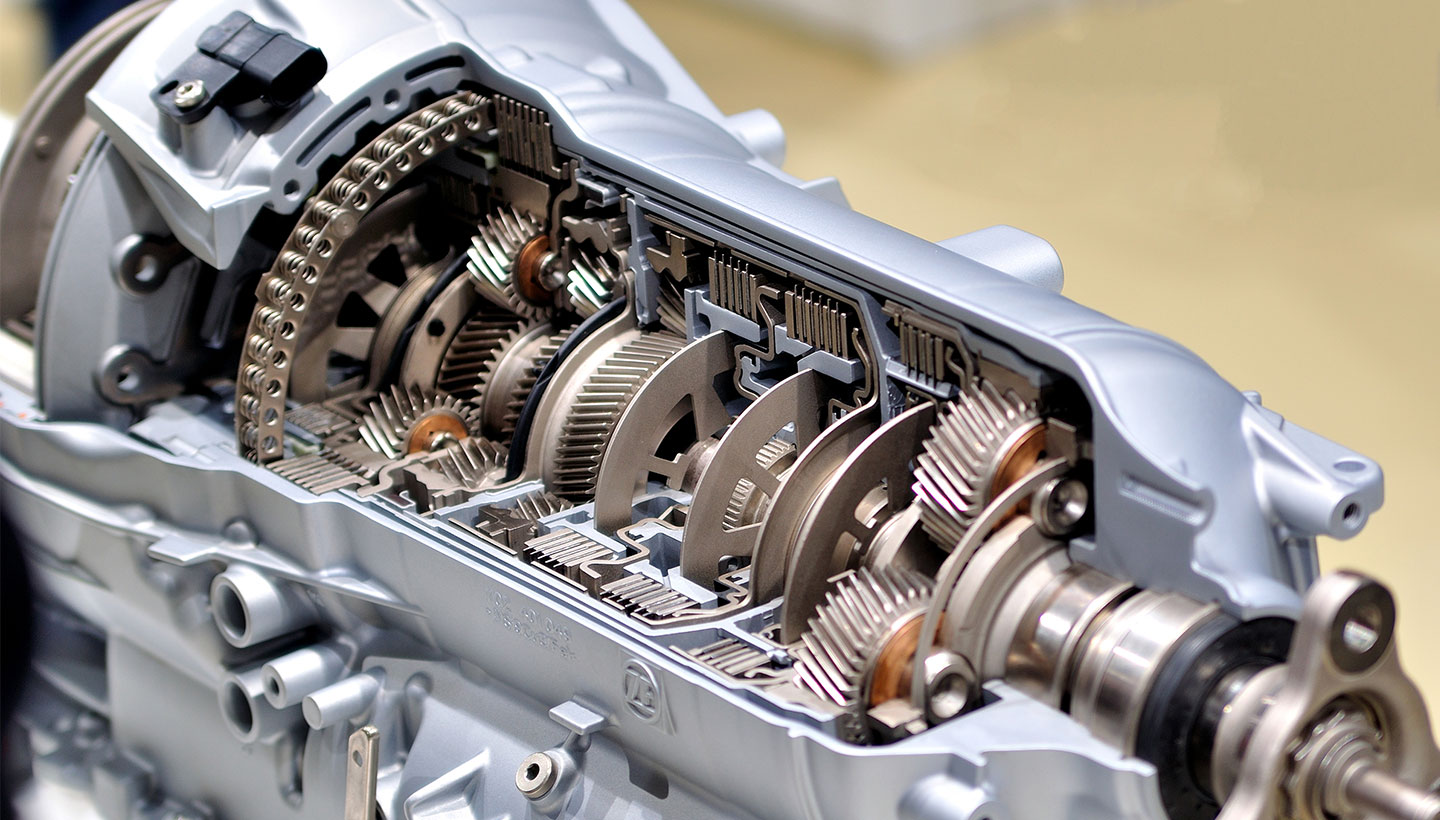

- Automotive Industry Investment casting is used to produce critical components such as exhaust manifolds, gears, and connectors that require durability and resistance to high temperatures.

- Medical Devices The precision and biocompatibility of stainless steel make it a popular choice for surgical instruments and implants.

- Industrial Equipment Components such as valves, pumps, and fittings that operate in corrosive environments are manufactured using stainless steel investment casting to ensure reliability and performance.

Technological Advancements in Investment Casting

Recent developments in investment casting technology have further enhanced its capabilities. Innovations such as 3D printing for pattern production allow for even greater design freedom and the ability to produce highly complex geometries. Additionally, advancements in automation and robotics have streamlined the casting process, improving efficiency, and reducing production times.

Furthermore, the introduction of advanced materials and alloys has expanded the potential applications of stainless steel investment casting. Manufacturers can now explore options that offer improved performance under extreme conditions, ensuring that parts meet the rigorous demands of modern applications.

Conclusion

Stainless steel investment casting is a remarkable manufacturing process that combines precision, efficiency, and versatility. As industries continue to evolve and demand increasingly complex components, the advantages of stainless steel investment casting will remain a cornerstone of modern manufacturing. With ongoing technological advancements, this method is poised to address future challenges, ensuring its relevance and utility across multiple sectors for years to come.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025