Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Innovative Solutions in Steel Casting and Foundry Technology for Modern Manufacturing

SS Casting Foundry A Cornerstone of Modern Manufacturing

In the ever-evolving landscape of manufacturing, the importance of precision and quality cannot be overstated. The SS Casting Foundry stands out as a vital player in this arena, specializing in the production of high-quality cast components that cater to various industries, including automotive, aerospace, and heavy machinery. This article explores the operations, technology, quality control measures, and contributions of SS Casting Foundry to the broader manufacturing ecosystem.

Operations of SS Casting Foundry

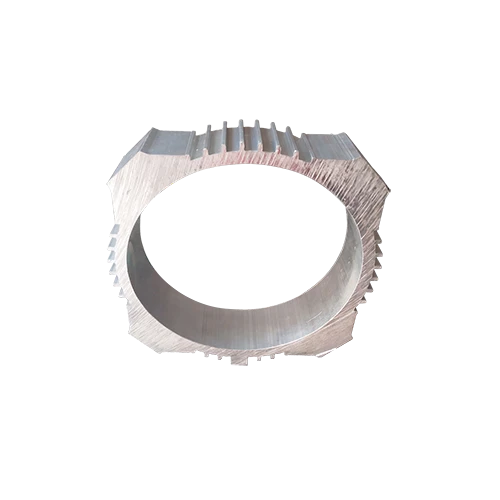

At the heart of SS Casting Foundry's operations is a commitment to excellence. The foundry utilizes advanced techniques in creating metal castings, including sand casting, investment casting, and die casting. Each method has its strengths, allowing the foundry to provide tailored solutions for different client needs. Sand casting, for instance, is ideal for producing large components with complex shapes, making it widely used in the automotive sector. Conversely, investment casting is favored for its ability to produce intricate parts with fine tolerances, essential in the aerospace industry.

The foundry's operations are characterized by state-of-the-art machinery and a skilled workforce. The integration of automated processes with traditional craftsmanship ensures that each product meets the highest standards. The facility is equipped with modern melting furnaces, CNC machining centers, and robotic arms that facilitate efficient production while minimizing human error.

Technology and Innovation

Innovation is a cornerstone of SS Casting Foundry’s philosophy. The foundry actively invests in research and development to improve manufacturing processes and explore new materials. One notable advancement is the use of environmentally-friendly technologies, which aim to reduce waste and energy consumption. These initiatives not only benefit the environment but also enhance the foundry’s competitiveness in a market that increasingly values sustainability.

Furthermore, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allows for precise modeling and simulation of casting processes. This technology enables engineers to predict potential issues before production begins, significantly reducing the risk of defects and ensuring that clients receive products that meet their specifications.

ss casting foundry

Quality Control Measures

Quality assurance is a pillar of SS Casting Foundry’s operations. The foundry adheres to stringent quality control processes at every stage of production, from the initial design to the final inspection. This rigorous approach guarantees that each casting not only meets industry standards but also fulfills the specific requirements of clients.

The foundry employs various testing methodologies, including non-destructive testing (NDT), which checks for internal flaws without damaging the component. Techniques such as ultrasonic testing and radiographic inspection are utilized to ensure that the castings are robust and reliable. Additionally, a dedicated quality assurance team monitors the entire production process, conducting regular checks and audits to maintain consistent quality levels.

Contributions to the Manufacturing Ecosystem

SS Casting Foundry’s impact extends beyond its production capabilities. By supplying high-quality cast components, the foundry plays a crucial role in the supply chains of numerous industries. The automotive sector, for instance, relies on castings for engine blocks, transmission cases, and suspension components. Similarly, the aerospace industry depends on precision cast components for structural and functional integrity.

Moreover, SS Casting Foundry is actively engaged in fostering partnerships with local suppliers and industry stakeholders. This collaboration not only strengthens the local economy but also promotes knowledge sharing and innovation within the manufacturing sector. In an era where globalization is often at the forefront of discussions, SS Casting Foundry’s dedication to supporting local businesses is commendable and essential for sustainable growth.

Conclusion

In conclusion, SS Casting Foundry exemplifies excellence in the manufacturing sector through its commitment to quality, innovation, and sustainability. By leveraging advanced technology while maintaining a focus on traditional craftsmanship, the foundry not only produces high-quality cast components but also contributes significantly to the broader manufacturing ecosystem. As industries continue to evolve, the role of SS Casting Foundry will remain pivotal in shaping the future of manufacturing, ensuring that it meets the demands of a fast-paced, ever-changing world. Its dedication to quality and innovation secures its place as a leader in the foundry industry, paving the way for continued growth and success.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025