Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Gen . 10, 2025 09:55

Back to list

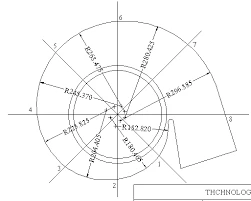

Pump Body

End cap aluminium products offer unique benefits to various industries, particularly in applications requiring durability, corrosion resistance, and a pleasing aesthetic. With decades of experience, aluminium end caps have established themselves as a highly sought-after architectural and industrial component due to their expert design and reliability.

In terms of authoritativeness, leading companies in the field have consistently backed aluminium end caps for their innovation and excellence. Companies like Hydro Extrusions and Constellium have developed ground-breaking technologies in aluminium processing, setting industry standards for quality and performance. Through years of research and development, these companies have produced aluminium end caps that meet international quality standards and are certified for use across various high-stakes industries. Trustworthiness, a vital component of end cap selection, is ensured through rigorous testing and quality assurance processes. End caps undergo stringent testing for stress, impact resistance, and durability, guaranteeing that each product not only meets but exceeds client expectations. Manufacturers also provide comprehensive warranties and technical support, ensuring customers receive lasting value and reliability. For clients looking to invest in aluminium end caps, consulting with experts and accessing verified reviews can make all the difference. Checking for certifications, such as ISO standards, can ensure the highest quality and performance consistency. Furthermore, working with reputable suppliers who provide clear and detailed specifications along with customization options guarantees that the chosen end caps will fulfill the specific needs of any project. In conclusion, aluminium end caps offer a blend of aesthetic appeal, durability, and versatility, making them indispensable in both industrial and architectural applications. Their proven performance and the trust placed in them by experts and authoritative manufacturers underscore their status as essential components in modern design and engineering.

In terms of authoritativeness, leading companies in the field have consistently backed aluminium end caps for their innovation and excellence. Companies like Hydro Extrusions and Constellium have developed ground-breaking technologies in aluminium processing, setting industry standards for quality and performance. Through years of research and development, these companies have produced aluminium end caps that meet international quality standards and are certified for use across various high-stakes industries. Trustworthiness, a vital component of end cap selection, is ensured through rigorous testing and quality assurance processes. End caps undergo stringent testing for stress, impact resistance, and durability, guaranteeing that each product not only meets but exceeds client expectations. Manufacturers also provide comprehensive warranties and technical support, ensuring customers receive lasting value and reliability. For clients looking to invest in aluminium end caps, consulting with experts and accessing verified reviews can make all the difference. Checking for certifications, such as ISO standards, can ensure the highest quality and performance consistency. Furthermore, working with reputable suppliers who provide clear and detailed specifications along with customization options guarantees that the chosen end caps will fulfill the specific needs of any project. In conclusion, aluminium end caps offer a blend of aesthetic appeal, durability, and versatility, making them indispensable in both industrial and architectural applications. Their proven performance and the trust placed in them by experts and authoritative manufacturers underscore their status as essential components in modern design and engineering.

Next:

Latest news

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025

Related PRODUCTS