Mobile:+86-311-808-126-83

Email:info@ydcastings.com

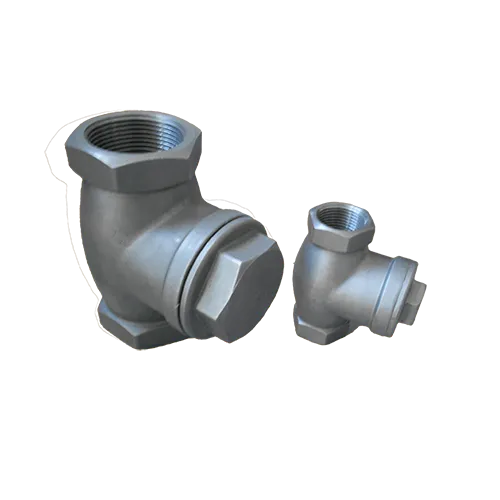

Metal End Caps for Pipe Sealing and Protection Applications

Understanding Pipe End Cap Metal Essential Components in Piping Systems

Pipe end caps, made of metal, play a crucial role in various piping systems across diverse industries. Whether in plumbing, oil and gas, or construction, these components are designed to seal the ends of pipes, preventing the escape of fluids and ensuring system efficiency.

What are Pipe End Caps?

Pipe end caps are fittings that cover the end of a pipe, effectively sealing it off. These caps can be manufactured from a variety of materials, but metal caps are particularly favored for their strength and durability. Metals like stainless steel, carbon steel, and aluminum are commonly used due to their resistance to corrosion and excellent mechanical properties. This makes them an ideal choice for high-pressure applications and environments where chemical exposure is likely.

Applications of Metal Pipe End Caps

The versatility of metal pipe end caps extends to many practical applications. In the oil and gas industry, for instance, these caps are used to secure pipelines and prevent leaks during transport. In water systems, they help maintain pressure and prevent contamination. Additionally, in construction, metal end caps are often employed in structural applications where the integrity of the piping system is paramount.

Benefits of Using Metal End Caps

pipe end cap metal

One of the primary advantages of using metal pipe end caps is their durability. Metal caps provide a robust barrier against external factors, which helps in reducing maintenance costs over time. They can withstand extreme temperatures and pressures, making them suitable for both hot and cold applications. Furthermore, metal end caps can be welded or bolted to pipes, ensuring a secure fit that minimizes the risk of leakage.

Another benefit is the ease of installation. Metal pipe end caps can be found in various sizes and specifications to match existing piping systems, allowing for quick and efficient installation without the need for specialized tools.

Considerations When Choosing Metal End Caps

When selecting metal pipe end caps, several factors should be considered. The type of metal is critical; for instance, stainless steel is preferred for environments that require resistance to corrosion. The size and pressure rating of the cap should also align with the specific requirements of the piping system. Additionally, the intended application—whether it involves high temperatures, corrosive substances, or high pressures—can influence the choice of material and design.

Conclusion

Metal pipe end caps are essential components in maintaining the integrity and efficiency of piping systems across various industries. Their durability, ease of installation, and effectiveness in preventing leaks make them a vital choice for engineers and contractors alike. As industries continue to evolve, the importance of reliable and robust end caps will only grow, underscoring the need for quality materials and thoughtful design in piping solutions.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025