Mobile:+86-311-808-126-83

Email:info@ydcastings.com

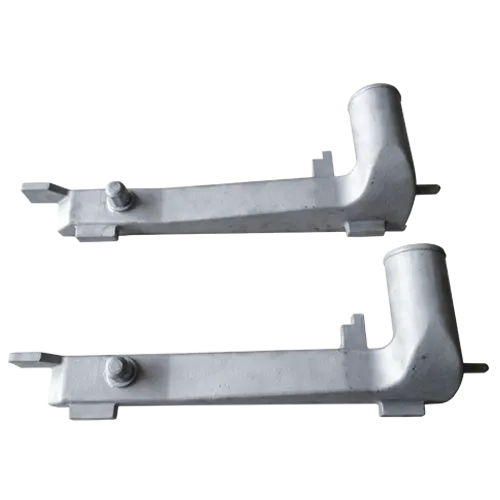

pipe caps steel

The Importance and Applications of Steel Pipe Caps

In the world of construction and manufacturing, various components are crucial for ensuring the integrity and functionality of piping systems. One such component is the steel pipe cap. Designed to cover the ends of pipes, these caps serve multiple purposes and are essential in various industrial applications. This article delves into the significance, types, and applications of steel pipe caps.

Steel pipe caps are vital for several reasons. Firstly, they provide a means to seal the ends of pipes, preventing the ingress of foreign materials, moisture, or contaminants that could compromise the integrity of the piping system. This sealing function is particularly important in industries that rely on the transportation of liquids, gases, and other substances, where any leakage could lead to operational inefficiencies or environmental hazards.

Another critical function of steel pipe caps is to provide protection to the threaded ends of pipes. Exposed threads can be prone to damage and corrosion, potentially leading to costly repairs or replacements. By using steel caps, companies can safeguard their investment and extend the lifespan of their piping systems. Furthermore, these caps contribute to safety by reducing the risk of accidental injuries from sharp edges or exposed pipe ends.

Types of Steel Pipe Caps

Steel pipe caps come in various shapes, sizes, and materials, catering to different industrial needs

. The two primary types of caps are1. End Caps These are used to close off the ends of pipes completely. They are typically available in different wall thicknesses and are designed to handle different pressure classes, ensuring compatibility with the piping system's requirements.

2. Threaded Caps These caps have internal threads that allow them to screw onto the external threads of pipes. This type of cap is often used in applications where easy access to the pipe's interior is required for maintenance or inspection.

These caps can be made from various steel grades, including carbon steel, stainless steel, and alloy steel. The choice of material depends on the specific requirements of the application, such as resistance to corrosion, temperature, and pressure.

pipe caps steel

Applications of Steel Pipe Caps

Steel pipe caps are widely used across several industries, highlighting their versatility and importance

1. Oil and Gas Industry In this sector, steel pipe caps are used to seal off terminated pipelines and prevent the escape of hydrocarbons. Ensuring that these systems are leak-free is essential for both safety and environmental protection.

2. Water Treatment Facilities Pipe caps are employed to safeguard unused outlets in water treatment plants. This is crucial to prevent contamination and maintain the quality of treated water.

3. Construction and Infrastructure In many construction projects, steel pipe caps are used during the installation phase to protect piping systems from debris and damage until the final connections are made.

4. Chemical Processing The chemical industry often requires caps that withstand corrosive substances. Steel pipe caps used in this sector are typically made from stainless steel or other corrosion-resistant materials to ensure safety and longevity.

5. Manufacturing In manufacturing plants, pipe caps are used in various applications, including heating and cooling systems. They help maintain system integrity by preventing blockages or disruptions caused by buildup or foreign objects.

Conclusion

Steel pipe caps are more than just simple accessories; they are critical components that play an essential role in the reliability and safety of piping systems across numerous industries. Their ability to seal, protect, and provide access makes them indispensable in applications ranging from oil and gas to chemical processing and construction. As industries continue to evolve and demand higher standards of safety and efficiency, the importance of steel pipe caps will remain paramount. Investing in high-quality caps tailored to specific needs will ensure that piping systems function optimally and securely, safeguarding both personnel and the environment.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025