Mobile:+86-311-808-126-83

Email:info@ydcastings.com

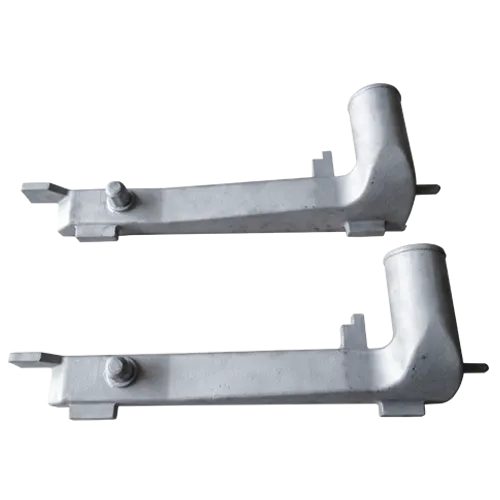

pipe blanking cap

Understanding Pipe Blanking Caps A Comprehensive Guide

In various industrial applications, ensuring the integrity and safety of piping systems is critical. One of the essential components used to achieve this is the pipe blanking cap. In this article, we will explore what pipe blanking caps are, their applications, materials, and installation methods, and highlight their significance in different industries.

What is a Pipe Blanking Cap?

A pipe blanking cap, often referred to simply as a blank cap, is a type of fitting designed to seal the end of a pipe or valve. This component effectively prevents the fluid from passing through an open end, thereby ensuring that the system maintains pressure and integrity. Blanking caps are essential in a variety of applications, including water supply systems, petrochemical facilities, and pressure vessels, where maintaining the flow and preventing leaks is paramount.

Applications of Pipe Blanking Caps

Blanking caps are used in multiple scenarios across various industries

1. Maintenance and Repair When valves or pipes need to be removed or serviced, blanking caps can be temporarily placed on the ends to prevent any fluid from leaking during maintenance. 2. System Modifications In cases where a portion of a piping system is being redesigned or modified, blanking caps can be used to securely close off any openings without the need for extensive reworking. 3. Testing and Inspection During pressure testing, blanking caps ensure that pressure is maintained within the system, allowing engineers to identify potential leaks and weaknesses in the piping. 4. Isolation of Sections When a specific section of a piping system needs to be isolated for any reason—such as replacement, cleaning, or inspection—blanking caps can effectively seal the ends of the isolated segment.

Materials Used in Pipe Blanking Caps

pipe blanking cap

Pipe blanking caps can be made from various materials, depending on the specific requirements of the application. Common materials include

- Steel Carbon and stainless steel blanking caps provide durability and resistance to high pressure, making them suitable for industrial applications. - Plastic For less demanding environments, like residential plumbing, plastic blanking caps are often used due to their lightweight nature and resistance to corrosion. - Bronze Used in marine applications, bronze offers excellent corrosion resistance in salty or humid environments.

Each material has its advantages, and the choice largely depends on the medium being transported, temperature, pressure conditions, and environmental factors.

Installation of Pipe Blanking Caps

Installation of a pipe blanking cap is generally straightforward but can vary based on the specific design and application. The general steps include

1. Preparation Ensure that the pipe end is clean and free of debris to prevent leaks. 2. Alignment Position the blanking cap over the open end of the pipe and align it properly. 3. Securing Depending on the type of cap, it may require threading, welding, or the application of sealants or gaskets to create a tight seal. 4. Testing After installation, conduct a pressure test to ensure that the system is leak-proof.

Conclusion

Pipe blanking caps play a crucial role in maintaining the efficiency and safety of piping systems in numerous industries. By providing a reliable method for sealing pipe ends, they facilitate maintenance, testing, and safe operation of fluid transport systems. Understanding their function, applications, and installation techniques is essential for engineers and technicians involved in piping design and maintenance. As industries continue to evolve and prioritize safety, the importance of these components will remain significant, ensuring that systems function smoothly and effectively.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025