Mobile:+86-311-808-126-83

Email:info@ydcastings.com

High Pressure Die Casting Solutions for Advanced Manufacturing and Product Development

Exploring High Pressure Die Casting A Deep Dive into Omen Technologies

High pressure die casting (HPDC) represents a revolutionary manufacturing technology that has transformed the production landscape in industries such as automotive, aerospace, and consumer electronics. Among the leading players in this domain is Omen Technologies, a company dedicated to leveraging advanced techniques to deliver high-quality die-cast products. This article explores the fundamentals of high pressure die casting, its process, advantages, and the innovations brought forth by Omen Technologies.

Understanding High Pressure Die Casting

High pressure die casting is a process used to produce metal parts by forcing molten metal into a mold at high speed and pressure. This technique is particularly favored for its ability to create complex shapes with tight tolerances, making it ideal for mass production. Typical metals used in HPDC include zinc, aluminum, and magnesium, with aluminum being the most common due to its strength-to-weight ratio and corrosion resistance.

The Process of HPDC

The HPDC process consists of several critical stages

1. Mold Preparation The manufacturing process begins with the design of the die, which is typically made from hard steel to withstand the high pressures involved. The die is lubricated to ensure smooth operation and easy removal of the finished part.

2. Melting the Metal The raw metal is heated in a furnace until it reaches its molten state. The temperature and composition of the metal are carefully controlled to ensure optimal flow and mechanical properties.

3. Injection Once the metal is molten, it is injected into the mold at high velocity using a plunger system. The pressure can reach up to several thousand psi, allowing the metal to fill intricate details in the mold before it solidifies.

4. Cooling and Ejection After injection, the metal is allowed to cool and solidify within the mold. Once this is done, the die is opened, and the finished part is ejected.

5. Trimming and Finishing The die-cast part often requires trimming to remove excess metal and additional finishing processes such as machining, polishing, or painting to meet specific quality standards.

Advantages of High Pressure Die Casting

HPDC offers numerous advantages that make it a preferred choice for many manufacturers

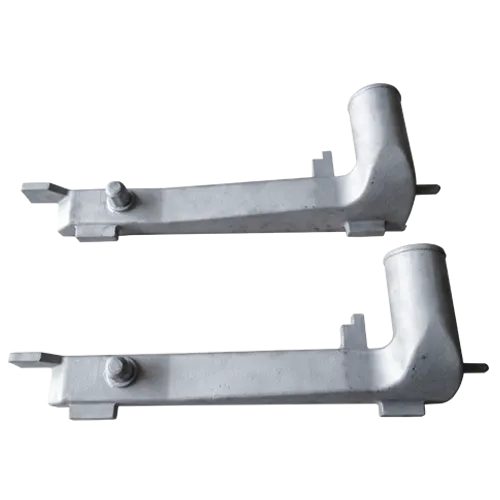

omen high pressure die casting

- High Precision The process allows for tight tolerances, making it suitable for applications where precision is critical.

- Surface Finish Parts produced through HPDC typically have an excellent surface finish, reducing the need for extensive post-processing.

- Material Efficiency The die-casting process minimizes waste, enabling manufacturers to use materials more efficiently.

- Mass Production HPDC is highly efficient for mass production, delivering thousands of parts in a relatively short time frame.

Omen Technologies Innovating in HPDC

Omen Technologies stands at the forefront of high pressure die casting innovation. The company utilizes cutting-edge technology to improve the efficiency and quality of its die-cast products. Here are some of the key innovations that set Omen apart

- Automated Processes Omen employs automated systems for mold handling, metal pouring, and part ejection, which enhances consistency and reduces cycle times.

- Advanced Materials The company actively researches and implements new metal alloys and combinations, optimizing the mechanical properties and performance of the final products.

- Sustainability Initiatives Omen is committed to sustainable manufacturing practices, incorporating recycling processes for metals and reducing waste generated during production.

- Collaborative Design The company works closely with clients to customize die designs, ensuring that the final product meets precise specifications and functional requirements.

Conclusion

High pressure die casting, particularly as advanced by Omen Technologies, represents a dynamic intersection of technology and manufacturing. With its ability to produce complex geometries, high precision, and efficient mass production, HPDC is poised to meet the evolving demands of various industries. As Omen continues to innovate, it exemplifies the future of manufacturing—one that values efficiency, quality, and sustainability. Through advancements in technology and a commitment to excellence, Omen is not only shaping the future of die casting but also setting new standards for the industry as a whole.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025