Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Art of Die Casting in Omen Production

The Allure of Omen Die Casting Crafting Precision and Artistry

In the realm of manufacturing, die casting is a pivotal process that has revolutionized how metals are shaped and utilized in various industries. Among the vast array of die casting techniques, Omen die casting stands out for its unique capability to produce intricate designs while ensuring superior quality and durability. This method combines advanced technology with artistry, enabling the creation of not just functional pieces, but also aesthetically pleasing components that appeal to a wide range of consumers.

Understanding Omen Die Casting

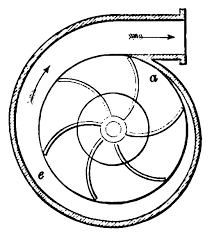

Omen die casting refers to a specialized method that focuses on producing high-quality metal components through a controlled and precise process. This technique typically involves melting metal, such as aluminum, zinc, or magnesium, and injecting it into a molded cavity under high pressure. Once the metal cools and solidifies, the mold is removed, revealing a finished product that is often ready for immediate use or further processing.

What distinguishes Omen die casting from other methods is its ability to produce complex shapes with exceptional accuracy. This precision allows manufacturers to create detailed textures and fine features that elevate the final product's overall design. Consequently, Omen die casting finds applications in various sectors, including automotive, aerospace, electronics, and medical devices.

Benefits of Omen Die Casting

One of the primary advantages of Omen die casting is its cost-effectiveness in mass production. The process minimizes waste and reduces the need for extensive machining, allowing manufacturers to produce high volumes of parts at a lower cost per unit. This efficiency is crucial in today's competitive market, where companies are continually seeking ways to optimize production and reduce expenses.

omen die casting

Moreover, the durability of die-cast products cannot be overstated. The Omen die casting process results in components that possess superior strength and resistance to wear and tear. This makes them ideal for applications that require long-lasting materials, leading to fewer replacements and repairs. Additionally, the smooth surface finish attainable through this method reduces the need for additional polishing, further enhancing production efficiency.

The Aesthetic Appeal of Omen Die Casting

Beyond its functional benefits, Omen die casting is increasingly recognized for its aesthetic potential. As designers and engineers collaborate, they can create products that not only perform well but also look visually stunning. The ability to integrate intricate designs, logos, and textures directly into the casting process means that companies can enhance their branding while providing consumers with products that stand out in the marketplace.

The versatility of materials that can be used in Omen die casting further enhances its appeal. Manufacturers can experiment with different metal alloys and finishes to produce unique effects, catering to a wide range of customer tastes. This flexibility allows for a greater variety of applications, making Omen die casting a preferred choice for designers who prioritize both style and substance.

Conclusion

In conclusion, Omen die casting represents a remarkable fusion of precision engineering and artistic design. With its unique ability to produce high-quality, intricate components at scale, this process is essential in various industries that demand both functionality and aesthetics. As technology continues to advance, the future of Omen die casting looks promising, offering endless possibilities for innovation and creativity. Businesses that leverage this technique stand to benefit not only from reduced production costs but also from the enhanced appeal of their products in a crowded marketplace. The artistry embedded in Omen die casting is not just a byproduct; it is a critical factor that shapes the future of manufacturing.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025