Mobile:+86-311-808-126-83

Email:info@ydcastings.com

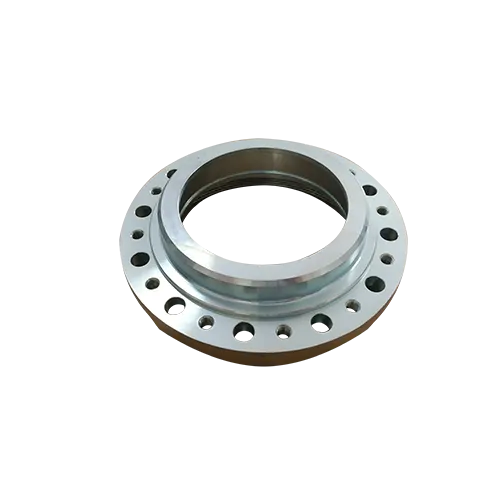

metal castings

The Intricacies of Metal Castings in Modern Manufacturing

Metal casting is a crucial manufacturing process that has shaped various industries by providing high-quality components necessary for numerous applications. The technique involves pouring molten metal into a mold to create a desired shape, and it is valued for its versatility, ability to produce complex geometries, and cost-effectiveness. As technology continues to advance, metal casting techniques are evolving, resulting in improved efficiency and enhanced product quality.

The metal casting process can be divided into several key stages pattern making, mold making, melting, pouring, and finishing. The first step, pattern making, involves creating a replica of the final product, usually made from materials like wood, plastic, or metal. This pattern is essential because it dictates the dimensions of the mold and, ultimately, the final cast. Accurate patterns result in improved precision and reduced material waste.

The Intricacies of Metal Castings in Modern Manufacturing

Next comes the melting of the metal. Different metals have varying melting points, and the choice of metal significantly affects the quality and properties of the final product. Common metals used in casting include aluminum, iron, bronze, and copper. The melting process is typically conducted in furnaces, and advanced technologies like induction heating are often employed for better control of temperature and faster melting times.

metal castings

Once the metal reaches its molten state, it is carefully poured into the prepared mold. This stage requires precision as the flow of metal must be controlled to prevent defects such as air pockets or inclusions. After pouring, the metal is allowed to cool and solidify, forming the desired shape. Cooling rates can affect the microstructure of the metal, influencing properties such as strength and durability.

After the casting has solidified, the next phase is finishing, where excess material is removed, and surface imperfections are addressed. Techniques such as machining, grinding, and polishing are typically employed to achieve the final specifications of the component. Finishing not only enhances the product's aesthetic appeal but also ensures it meets functional requirements.

While traditional casting methods have served industries well, advancements in technology, such as 3D printing of molds and new alloy development, are transforming metal casting. These innovations allow for greater design freedom and reduced lead times, making it possible to produce intricate designs that were once deemed impossible. Furthermore, with an increasing emphasis on sustainability, companies are exploring ways to recycle scrap metal and minimize waste throughout the casting process.

In conclusion, metal casting is a foundational process in contemporary manufacturing, providing essential components across a myriad of sectors, including automotive, aerospace, and construction. The ongoing enhancements in casting techniques and materials will undoubtedly continue to drive the industry forward, allowing manufacturers to meet the growing demand for complex and high-quality products. As we move into an era of advanced manufacturing, metal casting stands poised to play a pivotal role in realizing innovative designs and efficient production processes.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025