Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Impeller Design for Enhanced Blending Efficiency and Performance

Understanding the Maxblend Impeller A Key Innovation in Fluid Mixing

In the realm of industrial mixing technology, the Maxblend impeller has emerged as a groundbreaking innovation designed to enhance the efficiency and effectiveness of fluid mixing processes. Its unique design and functionality have made it a favored choice across diverse applications, from chemical processing to food and beverage production. This article explores the features, advantages, and applications of the Maxblend impeller, highlighting its significance in modern manufacturing.

Features of the Maxblend Impeller

The Maxblend impeller is characterized by its distinctive geometry, which allows for superior fluid mixing capabilities. Unlike traditional impeller designs, the Maxblend features an optimized blade configuration that promotes radial and axial flow patterns. This dual flow action significantly reduces dead zones and ensures a more uniform distribution of solids, liquids, and gases within the mixture.

One of the most notable features of the Maxblend impeller is its adaptability. It can be utilized in various tank designs, including those with challenging geometries. The impeller is engineered to operate efficiently at both high and low speeds, making it suitable for different viscosity levels and flow conditions. Moreover, it is constructed from high-quality materials that resist corrosion and wear, ensuring durability and longevity in demanding industrial environments.

Advantages of the Maxblend Impeller

The advantages of the Maxblend impeller are numerous. One of the primary benefits is its ability to enhance mixing efficiency. Its design minimizes energy consumption while maximizing mixing performance, leading to faster processing times and reduced operational costs. This efficiency translates to improved quality and consistency of the final product, which is particularly crucial in industries where precision is vital.

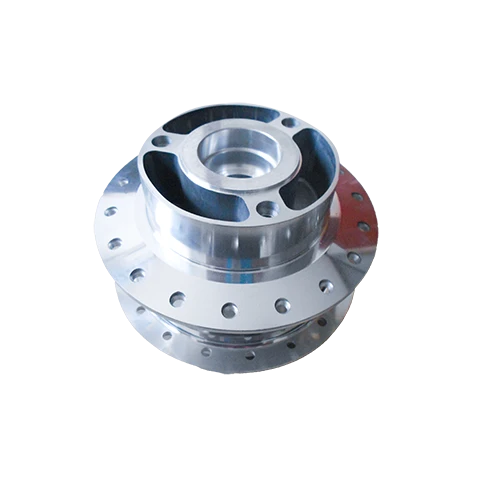

maxblend impeller

Another key advantage is its versatility. The Maxblend impeller is capable of handling a wide range of materials, including shear-sensitive products, complex slurries, and high-viscosity fluids. This versatility makes it an ideal choice for manufacturers looking to optimize their mixing processes across various product lines.

Furthermore, the Maxblend impeller promotes better heat transfer during mixing operations, which is essential in processes such as emulsion formation and chemical reactions. By ensuring a more uniform temperature distribution, it contributes to enhanced reaction kinetics and product quality.

Applications of the Maxblend Impeller

The applications of the Maxblend impeller are vast. In the chemical industry, it is used for the mixing of solvents, catalysts, and reaction mixtures, where achieving uniformity is crucial for successful chemical transformations. In the food and beverage industry, the impeller plays a vital role in ensuring that ingredients are mixed uniformly, contributing to the consistent taste and texture of products.

Moreover, the Maxblend impeller is widely utilized in pharmaceutical manufacturing, where precise mixing can impact drug efficacy and safety. Its ability to handle sensitive mixtures without causing damage is a significant advantage in this highly regulated industry.

In conclusion, the Maxblend impeller represents a significant advancement in fluid mixing technology. Its innovative design offers numerous benefits, including enhanced mixing efficiency, versatility, and improved heat transfer. As industries continue to evolve and demand more efficient and reliable mixing solutions, the Maxblend impeller is poised to play a critical role in optimizing manufacturing processes and ensuring product quality. Manufacturers looking to improve their mixing operations would do well to consider the advantages offered by this state-of-the-art impeller technology.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025