Mobile:+86-311-808-126-83

Email:info@ydcastings.com

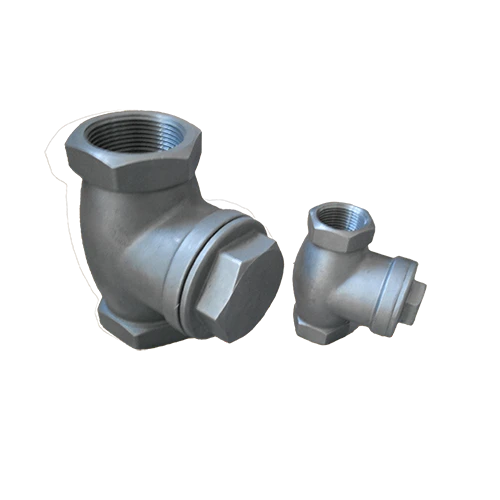

male threaded cap

Understanding Male Threaded Caps A Comprehensive Guide

Male threaded caps are essential components widely used in various industries, including plumbing, manufacturing, and construction. These caps serve the primary function of sealing or capping off male threads on pipes and tubes, ensuring a secure and leak-free connection. With their simple design and practical application, male threaded caps are critical in maintaining the integrity of fluid systems.

What are Male Threaded Caps?

Male threaded caps are devices that feature internal threading, allowing them to screw onto a male-threaded pipe or fitting. They come in various materials, such as plastic, brass, stainless steel, and more, to cater to different application needs. The choice of material often depends on factors such as the type of fluid being transported, pressure requirements, and environmental conditions.

Applications of Male Threaded Caps

These caps are employed in numerous applications across different sectors

1. Plumbing In residential and commercial plumbing, male threaded caps are used to close off pipe ends temporarily or permanently. They help prevent leaks in the plumbing system when repairs or alterations are made.

2. Hydraulics and Pneumatics In hydraulic systems, these caps help seal fluid-carrying tubes and pipes, minimizing the risk of contamination and ensuring the system operates efficiently.

3. Manufacturing Male threaded caps are often used in the production of various components, including valves and fittings, ensuring that the products are sealed correctly during the manufacturing process.

4. Automotive Industries In vehicles, these caps can be found in fuel systems and cooling systems to seal threads on hoses and fittings, preventing leaks and protecting essential fluids.

Advantages of Using Male Threaded Caps

The use of male threaded caps offers several advantages

male threaded cap

- Leak Prevention By securely capping off male threads, these caps prevent leaks that can lead to expensive repairs and potential damage to systems and environments

.- Versatility Available in numerous sizes and materials, male threaded caps can be used in a wide range of applications across different industries.

- Ease of Use Installation is straightforward, requiring minimal tools. This ease of use streamlines repairs and maintenance processes.

- Cost-Effective Given their durability and effectiveness, male threaded caps offer a cost-effective solution to sealing needs. Their ability to prevent leaks can save businesses significant amounts in potential repair costs.

Selecting the Right Male Threaded Cap

When choosing a male threaded cap, it is important to consider several factors

- Material Depending on the application and the fluid involved, select a material that can withstand the required temperatures and pressures. For example, stainless steel is often chosen for its durability and resistance to corrosion, while plastic caps may be suitable for less demanding applications.

- Size and Thread Type Ensure that the cap fits the specific male threads. The size and thread type (e.g., NPT, BSP) must match to achieve a proper seal.

- Operating Environment Consider the environmental conditions, such as exposure to chemicals or extreme temperatures, to select a cap that can withstand these challenges.

Conclusion

Male threaded caps play a crucial role in ensuring the efficient and leak-free operation of various fluid systems. Their versatility and ease of use make them indispensable in plumbing, manufacturing, and automotive industries. By understanding their applications, advantages, and selection criteria, professionals can make informed decisions that enhance the functionality and reliability of their systems. As industries continue to evolve, the demand for high-quality male threaded caps will only increase, underscoring their importance in modern engineering and infrastructure.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025