Mobile:+86-311-808-126-83

Email:info@ydcastings.com

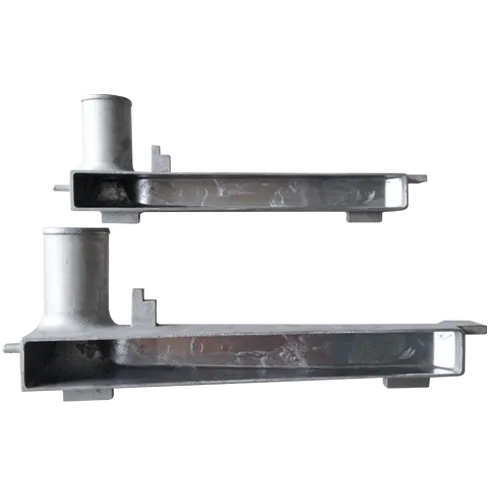

macerator impeller

Understanding the Macerator Impeller Functionality and Applications

A macerator impeller plays a crucial role in various industries, particularly in waste management and wastewater treatment. This specialized device is designed to mechanically break down solids into smaller particles, facilitating more efficient processing and disposal. Its applications range from household sewage systems to large-scale industrial operations, underscoring its versatility and importance.

The Mechanism of a Macerator Impeller

At its core, the macerator impeller is a rotating component that utilizes centrifugal force to shred and disperse materials. This mechanism consists of blades or paddles that are strategically arranged to maximize efficiency. When the impeller spins, it generates a significant amount of force, causing solid waste to be subjected to intense shear, thus breaking it down into finer pieces.

The design of the impeller is critical to its performance. Engineers often create impellers with varying blade shapes and sizes depending on the specific type of waste being processed. For example, in residential settings, macerators often handle human waste and toilet paper, while industrial macerators may deal with tougher materials like food scraps or manufacturing refuse. The right design ensures that the macerator can effectively reduce the size of these materials, thus preventing clogs and ensuring smoother operation in downstream processes.

Applications of Macerator Impellers

One of the primary applications of macerator impellers is in sewage systems. In these contexts, macerators help to manage human waste by breaking it down before it enters the sewage pipes. This is particularly important in homes that are not connected to municipal sewer systems, as macerators allow for the safe and efficient disposal of waste.

macerator impeller

In industrial settings, macerator impellers are equally vital. They are commonly used in food processing plants to handle organic waste, such as fruit and vegetable scraps. By reducing the size of these materials, macerators can facilitate composting or further processing, thereby minimizing landfill contributions and promoting sustainability.

Moreover, the pharmaceutical and chemical industries utilize macerators for the efficient disposal of various solid wastes. In these applications, the macerator ensures that hazardous materials are reduced to a manageable size, allowing for safer handling and transport.

Benefits of Using Macerator Impellers

The use of macerator impellers offers several benefits. First and foremost, they significantly reduce the volume of waste, leading to lower disposal costs and more efficient waste management practices. Additionally, by breaking down materials, macerators help prevent clogs and backups in plumbing systems, which can lead to costly repairs and environmental hazards.

Furthermore, macerators promote sustainability by facilitating the recovery of organic materials for composting or recycling. This not only reduces the burden on landfills but also contributes to the circular economy, where waste is transformed into valuable resources.

Conclusion

In summary, macerator impellers are essential components in waste management systems across various industries. Their ability to effectively break down solids enhances both efficiency and sustainability in waste disposal processes. As industries continue to focus on improving waste management practices and reducing environmental impact, the importance of macerator impellers will undoubtedly grow, highlighting the need for ongoing innovation and development in this field. By understanding their function and applications, stakeholders can better appreciate the critical role that macerator impellers play in creating a more sustainable future.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025