Mobile:+86-311-808-126-83

Email:info@ydcastings.com

low temperature metal casting

Low Temperature Metal Casting A Comprehensive Overview

Low temperature metal casting is an innovative approach in the field of metallurgy that involves the melting and solidification of metals at lower temperatures than conventional methods. This technique is particularly beneficial for metals that have relatively low melting points, such as lead, tin, and certain aluminum alloys. The process allows for the production of intricate metal parts with enhanced mechanical properties while reducing energy consumption and minimizing environmental impact.

One of the primary advantages of low temperature casting is its ability to preserve the microstructure of the metal. Traditional casting methods often expose metals to high temperatures that can lead to undesirable phase changes or grain growth, adversely affecting the material's properties. By using lower temperatures, manufacturers can maintain a fine grain structure, resulting in improved strength and ductility. This is particularly crucial in applications where performance is paramount, such as in aerospace and automotive industries.

In addition to the preservation of material properties, low temperature metal casting reduces the overall energy costs associated with the manufacturing process. Conventional metal casting can require significant energy to achieve and maintain high temperatures, contributing to higher operational costs and environmental emissions. Low temperature methods, on the other hand, utilize less energy, making them a more sustainable choice for metal fabrication. This is especially relevant as industries are increasingly focusing on reducing their carbon footprint and embracing greener practices.

low temperature metal casting

Furthermore, low temperature casting facilitates greater versatility in design and application. The ability to cast complex shapes and intricate components enhances the creative freedom of designers and engineers. This means that parts can be produced with minimal machining, which reduces material waste and further contributes to the sustainability of the process. Special alloys can also be developed for specific applications, tailored to meet the precise requirements of different industries.

However, it's important to note that low temperature metal casting does come with its challenges. The range of metals that can be effectively utilized is somewhat limited, and the processing techniques may require specialized knowledge and equipment. Additionally, the properties of low temperature cast metals may differ from those produced at higher temperatures, necessitating thorough testing and quality control.

In conclusion, low temperature metal casting presents a promising alternative to traditional casting methods, offering numerous advantages in terms of efficiency, sustainability, and material performance. As technology continues to evolve, this method is likely to play an increasingly vital role in the future of metallurgy and manufacturing.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

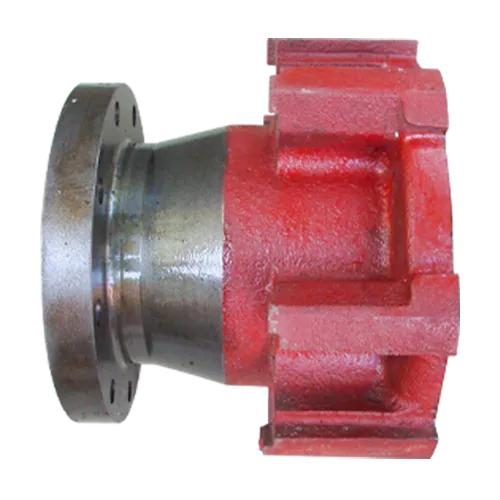

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025