Mobile:+86-311-808-126-83

Email:info@ydcastings.com

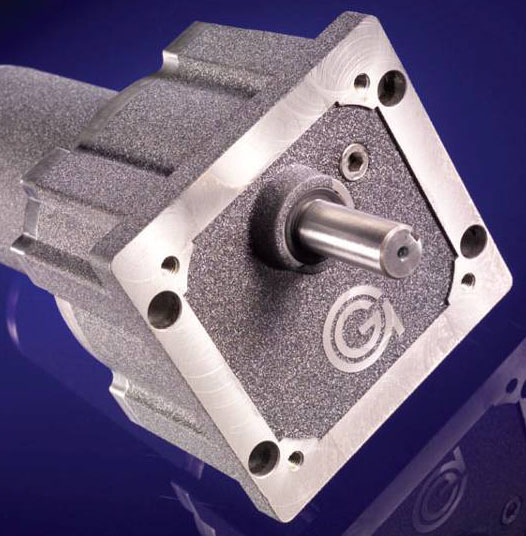

Connector bracket

When selecting an impeller for a pump, various factors come into play to ensure the efficiency and longevity of the system. Impellers are crucial components that directly influence a pump's performance by converting rotational energy into fluid movement. Understanding the nuances of impeller design and function can drastically enhance the effectiveness of your industrial and residential pumping solutions.

Impeller materials hold significant importance in deciding their application suitability. Commonly, impellers are constructed from materials such as stainless steel, cast iron, or plastics. Stainless steel impellers are renowned for their resistance to corrosion, making them ideal for use in environments with harsh chemicals or saltwater exposure. On the other hand, cast iron impellers, though heavier, offer robust mechanical strength and are suitable for operations involving abrasive materials. The type of impeller also affects the pump's efficiency and application. Centrifugal pumps, one of the most common types in use today, often feature closed, open, or semi-open impellers. Closed impellers are widely used in clear liquid applications due to their high efficiency and ability to maintain consistent flow rates. They feature shrouds on each side, offering better support and reduced chances of bending under pressure. However, their complexity often makes them susceptible to clogging, thus less ideal for applications involving particulates.

Open impellers, less prone to clogging due to their straightforward design, are suitable for fluids containing solids. Their structure offers simplicity in terms of maintenance and cleaning, favoring industries dealing with wastewater or slurry. Semi-open impellers bridge the gap, offering a balance by delivering moderate efficiency and handling small particulates without significant clogging risks.

Proper sizing of the impeller is another critical factor. An appropriately sized impeller ensures that the pump operates at optimal energy levels, reducing operational costs and extending the lifespan of the pump system. It's essential to match the impeller size with the required flow rate and head. Over-sizing can lead to inefficiency and energy waste, while under-sizing may cause excessive wear and motor overload.impeller on pump

Balancing the impeller is vital to prevent vibrations and extend the lifespan of both the pump and the motor. Imbalance in an impeller leads to increased wear and tear, potentially resulting in premature failures. Regular maintenance checks and using precision balancing techniques can mitigate these issues, ensuring smooth operations.

Incorporating the latest technologies can further enhance impeller performance. Computational Fluid Dynamics (CFD) modeling is a tool used by many engineers to predict and improve the fluid dynamics around the impeller, tailoring designs to specific applications. By leveraging such advanced techniques, businesses can achieve higher efficiency rates, reduced energy consumption, and lower operational costs.

Experienced technicians should handle the selection and maintenance of pump impellers. Their expertise ensures that every aspect of the pump system is fine-tuned for superior performance, which attributes to enhanced reliability, reduced downtime, and improved overall productivity.

In conclusion, the choice of an impeller plays an integral role in the efficiency and efficacy of a pump system. Through careful consideration of material, design, sizing, and balance, along with leveraging modern technologies, businesses can optimize their pump systems for greater performance, demonstrating the importance of expertise and authoritative guidance in selecting the perfect impeller.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025