Mobile:+86-311-808-126-83

Email:info@ydcastings.com

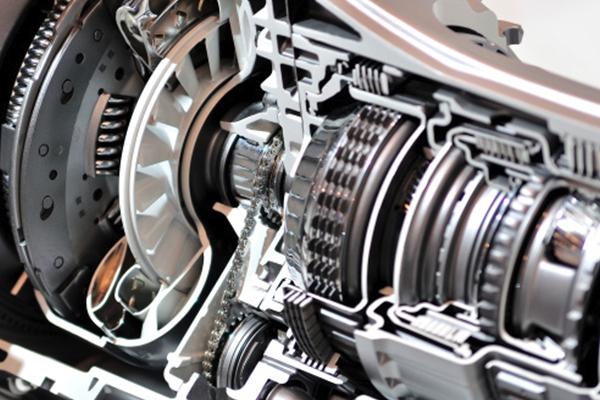

impeller in submersible pump

The Role of Impellers in Submersible Pumps

Submersible pumps are essential devices used in a variety of applications, from managing groundwater resources to providing efficient water transfer in industrial and agricultural settings. At the heart of these pumps lies a critical component known as the impeller. This article explores the function of impellers in submersible pumps and their significance in overall pump performance.

The Role of Impellers in Submersible Pumps

One of the key advantages of using an impeller in a submersible pump is its ability to generate high pressure and flow rates. This is particularly important in applications where water needs to be lifted from deep underground, such as in borehole pumping or in drainage systems. A well-designed impeller creates a high-velocity flow, allowing fluids to be pushed upward through the pump and out into the desired location.

impeller in submersible pump

There are various types of impellers used in submersible pumps, each suited for specific applications. Open impellers, characterized by their lack of shrouds, are often used for pumping fluids that may contain solids or debris. They provide a clear pathway for the fluid, minimizing the risk of clogging. Closed impellers, on the other hand, are more efficient for moving clean liquids and are designed for higher pressure applications. The choice of impeller type depends largely on the characteristics of the fluid being pumped and the specific requirements of the application.

Material selection is also crucial when it comes to impellers. Common materials include stainless steel, bronze, and thermoplastics. Stainless steel impellers are known for their durability and resistance to corrosion, making them ideal for pumping aggressive fluids. Bronze offers a balance of strength and corrosion resistance, while thermoplastics are lightweight and resistant to chemical degradation, providing versatility in various environments.

Moreover, the performance of an impeller is closely linked to its dimensions and design parameters, such as the number of vanes, width, and diameter. These factors play a crucial role in determining the pump's operational efficiency and its ability to handle different flow rates and pressures.

In conclusion, the impeller is a vital component of submersible pumps, influencing their effectiveness and suitability for different applications. Understanding the various types of impellers and their characteristics can help in selecting the right pump for specific needs, ensuring efficient operation and longevity. With advancements in technology and materials, the future of impeller design continues to evolve, promising even greater efficiencies and capabilities in submersible pumping systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025