Mobile:+86-311-808-126-83

Email:info@ydcastings.com

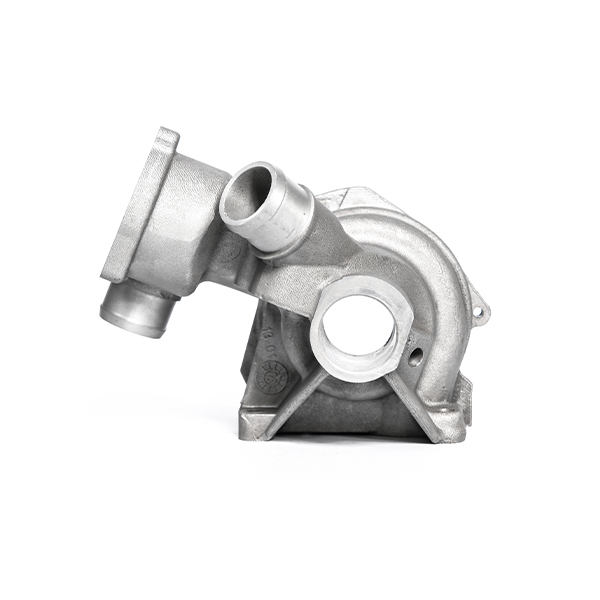

Leading Manufacturers of Impeller Casting for High-Quality Industrial Applications

Impeller Casting Manufacturers An Overview of the Industry

In the world of industrial manufacturing, impellers are critical components used in various applications, including pumps, compressors, and turbines. The manufacturing process for these intricate parts is known as impeller casting, a method that has gained significant traction due to its ability to produce highly complex shapes with excellent dimensional accuracy. This article aims to explore the landscape of impeller casting manufacturers, highlighting their importance, processes, and the factors driving the market.

Understanding Impeller Casting

Impeller casting involves pouring molten metal into a mold to form the shape of an impeller. This manufacturing technique is preferred for its versatility and efficiency, allowing manufacturers to create components that meet specific operational requirements. The materials commonly used in impeller casting include aluminum, bronze, and various alloys, each chosen for their unique properties such as weight, strength, and resistance to corrosion.

The Role of Impeller Casting Manufacturers

Impeller casting manufacturers play a crucial role in the supply chain. They not only produce impellers but also ensure that these components meet the strict quality standards required for various industries, including aerospace, marine, automotive, and chemical processing. The expertise of these manufacturers allows them to offer customized solutions tailored to the specific needs of their clients.

These manufacturers are equipped with advanced technologies and machinery, enabling them to produce high-quality castings at scale. This includes the use of computer-aided design (CAD) for precise specifications, and computer numerical control (CNC) machines for manufacturing accuracy. Furthermore, many manufacturers employ advanced casting methods such as investment casting, sand casting, and vacuum casting, depending on the project requirements.

Market Trends and Growth Drivers

impeller casting manufacturers

The market for impeller casting is expected to grow in the coming years, driven by several factors. First and foremost, the increasing demand for energy-efficient pumps and compressors in the industrial sector is fostering the need for specialized impellers. As industries strive to improve operational efficiency and reduce energy consumption, the focus on high-performance impellers has intensified.

Additionally, the rise of automation and the Internet of Things (IoT) is influencing manufacturing processes. Manufacturers are investing in smart technologies that allow for real-time monitoring and high levels of customization, further enhancing product quality and reducing lead times.

Sustainability is another significant trend affecting the impeller casting industry. Manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials and implementing waste reduction strategies. This shift not only appeals to environmentally conscious consumers but also helps companies comply with strict regulations.

Challenges Faced by Manufacturers

Despite the positive growth outlook, impeller casting manufacturers face several challenges. The most prominent is the fluctuating prices of raw materials, which can impact production costs. Additionally, there is a constant pressure to innovate and improve manufacturing processes to stay competitive in a crowded market. The ability to attract skilled labor is also critical, as the specialized nature of casting requires experienced workers to ensure quality and efficiency.

Conclusion

Impeller casting manufacturers are vital players in various industries, producing essential components that drive the efficiency of machinery and other applications. As the industry evolves, embracing technology and sustainability will be key to meeting future demands. With the right strategies in place, manufacturers can navigate the challenges ahead while contributing to the advancement of industrial manufacturing. By focusing on quality, innovation, and customer satisfaction, impeller casting manufacturers can ensure their relevance and success in an ever-changing market landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025